Fertilizer International 528 Sep-Oct 2025

11 September 2025

Ammonia in the fertilizer value chain

FERTILIZER TECHNOLOGY SHOWCASE

Ammonia in the fertilizer value chain

Stamicarbon, the nitrogen technology licensor of NEXTCHEM, is pioneering future-proof solutions for low-carbon production with two ammonia designs, each tailored to specific project scales, feedstock types, and sustainability goals. Deepak Shetty, Rolf Postma, and Nikolay Ketov of Stamicarbon (NEXTCHEM) look at how the arrival of these technologies will shape the future of the low-carbon economy – across fertilizer, fuels, and the evolving clean energy market.

Growing demand, changing markets

Global ammonia production is forecast to rise in future, attended by further growth in both market value and production capacity. Currently, this expansion is occurring primarily in both the fertilizer sector and ammonia’s traditional industrial applications, driven upwards by factors such as population growth and increasing food demand.

Beyond its conventional role as the key building block for nitrogen fertilizers, ammonia is also emerging as a clean energy carrier, particularly as a fuel and hydrogen vector for decarbonising hard-to-abate sectors.

Ammonia is relatively easy to store and transport in bulk, benefitting from a century-old global production and supply network. This extensive infrastructure is now being repurposed to support the energy transition, with existing ammonia storage, shipping, and port facilities offering a practical solution for moving renewable energy from centres of abundance to centres of demand.

Given that global ammonia production – driven by agriculture demand and its use as an energy vector – is set to increase significantly in coming years, the question is no longer whether demand will grow, but how fast: will ammonia demand simply track global population and economic growth, or accelerate faster as it becomes an essential component of the low-carbon economy?

Reducing the industry’s footprint

Ammonia synthesis, while playing a central role in global food production, is also a notable contributor to industrial CO2 emissions. Reducing this footprint remains a key objective across the industry, with technology providers and producers exploring new pathways to cut fertilizer value chain emissions.

Each and every ammonia decarbonisation route has a role to play – regardless of whether they generate ‘blue’, ‘green’ or other colour-coded products. Blue ammonia builds on established large-scale fossil-based processes, incorporating carbon capture to reduce emissions in the near term. Green ammonia, on the other hand, uses renewable electricity to produce hydrogen via electrolysis, offering a fully sustainable pathway with no direct carbon emissions. Both approaches will be critical as the ammonia industry adapts to meet higher demand and achieve sustainability objectives.

Stamicarbon, the nitrogen technology licensor of NEXTCHEM, is pioneering future-proof solutions for low-carbon production with two ammonia designs, each tailored to specific project scales, feedstock types, and sustainability goals. Whatever the priority, Stamicarbon offers a technology option to match – whether that’s small- to medium-scale green ammonia production from renewable electricity, or large-scale blue ammonia production from fossil sources with integrated carbon capture, utilisation, and storage (CCUS). In all cases, the emphasis is on highly efficient processes, maximum energy integration, and minimised emissions.

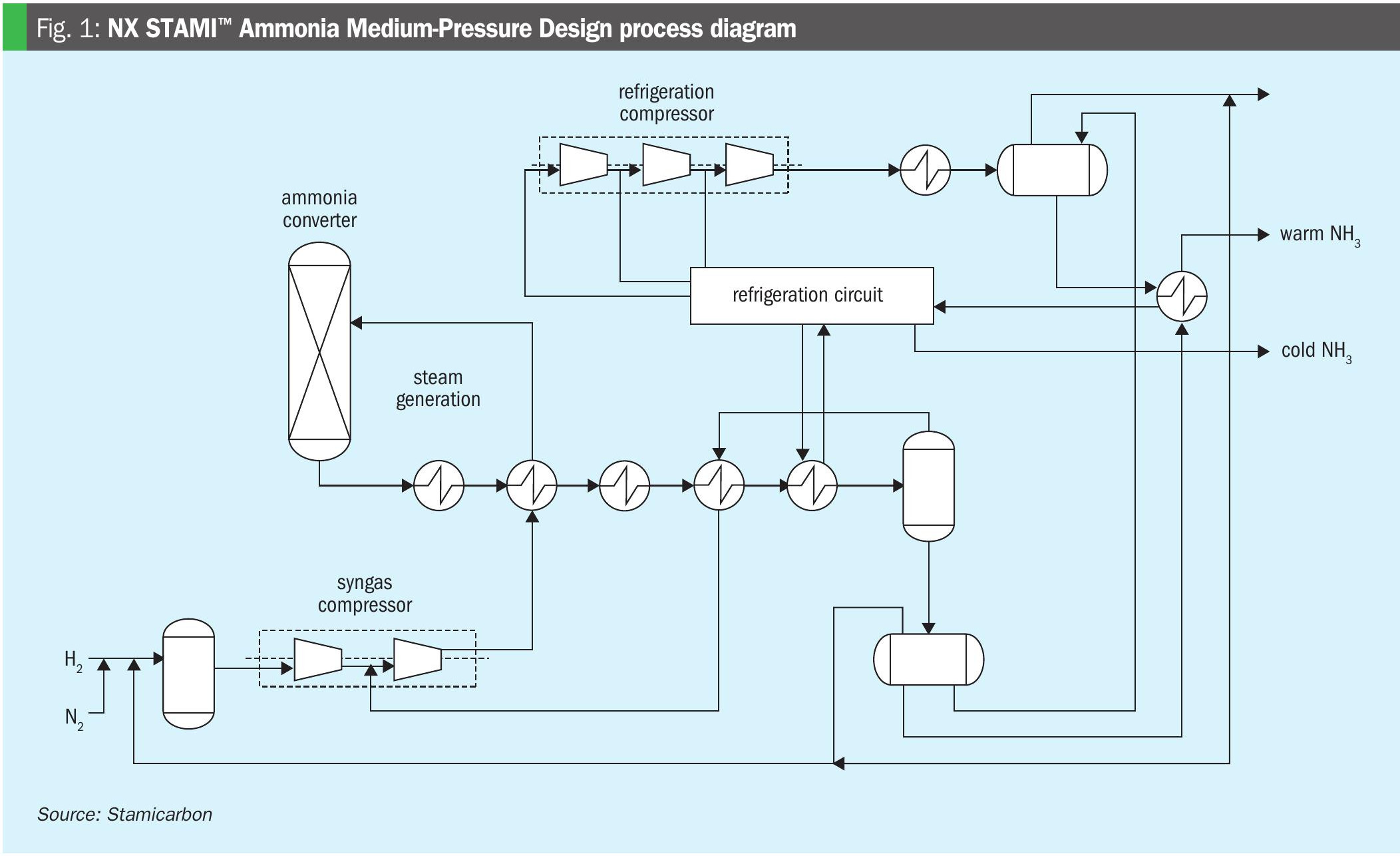

Large scale, high efficiency

To meet the growing demand for cost-efficient, high-performance ammonia production at industrial scale, Stamicarbon offers the NX STAMI™ Ammonia Medium-Pressure Design (Figure 1). This solution builds on the proven Haber-Bosch process, optimised for capacities ranging from 50 to 3,500 metric tonnes per day (t/d). It is particularly well-suited for large-scale ammonia plants using natural gas or other feedstocks and can be effectively integrated with front-end technologies such as steam methane reforming (SMR), autothermal reforming (ATR), and CCUS systems.

With more than 45 industrial references, including large-scale installations, the design offers a reliable and economically viable option for producers seeking to balance scale, efficiency, and emissions performance.

In this design, ammonia synthesis takes place in a multi-bed radial-flow reactor improved to minimise pressure drop and maximise per-pass conversion efficiency. Essentially, the NX STAMI™ medium-pressure design can maximise the per-pass conversion of hydrogen and nitrogen with the smallest possible catalyst volume.

The converter’s first catalyst bed has superior temperature control. This feature enables more efficient operation and extends catalyst life by avoiding hot spots. The result is a highly efficient synthesis loop that improves ammonia yield while consuming less energy. The design is also flexible and, by tailoring key operating parameters (pressure, flow rates, recycle ratios) to the client’s individual needs, can be modified for optimal performance in different scenarios.

Conventional large-scale ammonia plants that use this NX STAMI™ design can be decarbonised by integrating carbon capture at the front-end. Stamicarbon offers advanced ATR technology, via its parent company NEXTCHEM, that is particularly advantageous for these types of ‘blue’ ammonia projects.

ATR, by yielding a high-pressure syngas stream with a high concentration of CO2 , makes downstream carbon capture far more efficient. In fact, carbon capture rates higher than 98% can be achieved by NEXTCHEM’s ATR-based ammonia production – with 40% less solvent circulation compared to a conventional amine-based technology.

NEXTCHEM’s ATR operates at a high pressure (60+ barg). This reduces the compression duty needed in the ammonia synthesis loop, compared to conventional lower pressure reforming, as well as reducing the reactor size versus a conventional ATR. This translates to a lower capital cost profile and lower operating costs.

Moreover, the ATR route uses well-proven and robust equipment and a simplified process scheme that improves overall energy efficiency rates. When coupled with CCUS, an ATR-based ammonia plant can achieve world-scale output with a significantly smaller carbon footprint.

Powered by Renewables

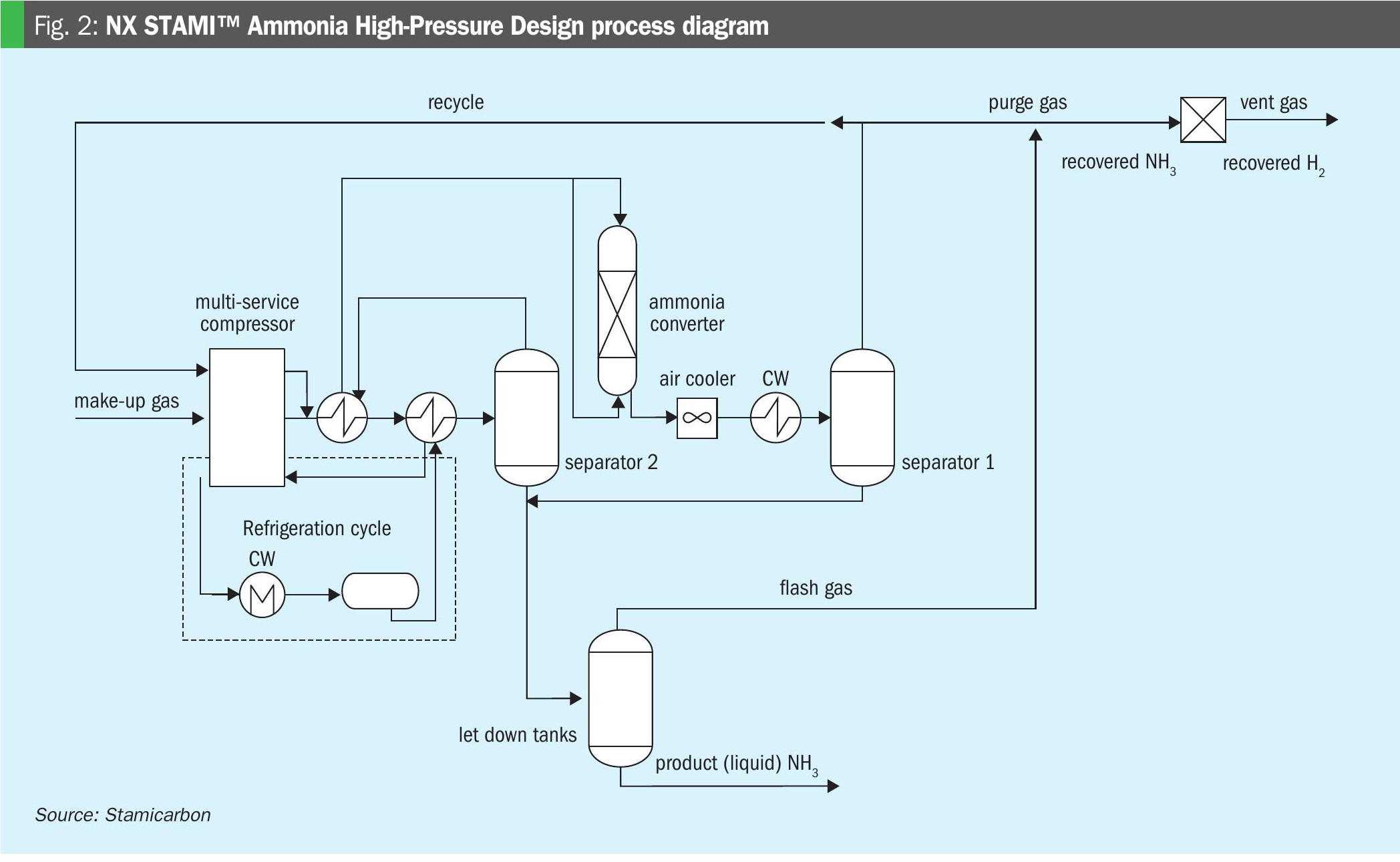

Most ‘green’ ammonia projects today fall within the small to medium capacity range, being limited by the availability of renewable electricity and the scale of electrolysis equipment. Stamicarbon offers the NX STAMI™ Ammonia High-Pressure Design (Figure 2) – a proven solution for production capacities from 50 t/d up to 500 t/d – to meet growing demand for green ammonia plants.

The process is specifically engineered for green ammonia production, where efficiency, small footprint and simplicity are key. It features a high-pressure synthesis loop operating at over 300 bar, with this enabling a high conversion rate per pass and reducing the need for recycle compression and refrigeration.

The elevated synthesis loop pressure allows the condensation of ammonia using cooling water in a single stage. This significantly reduces the overall equipment count by eliminating the need for a refrigeration compressor. This operational simplification reduces capital expenditure for the synthesis section alone by an estimated 25-30%, making the NX STAMI™ high-pressure design a cost-effective and scalable choice for green ammonia production.

The single-bed axial-flow ammonia converter also features a compact tubular reactor design. Inside the converter, heat exchanger tubes are submerged within the catalyst bed to carefully control the temperature. This precise temperature control prolongs catalyst life and maintains performance by preventing hot-spot formation and catalyst sintering. The inclusion of an integrated start-up heater within the converter also ensures the reactor heats up smoothly during plant start-up.

A single, electrically driven reciprocating compressor is also used to handle both fresh make-up gas and recycle gas in the synthesis loop. This minimises the number of compressors required, improving reliability and cutting maintenance costs.

Overall, the converter and other equipment are more compact, thanks to the high operating pressure. This means the overall footprint of the plant remains very small – a key benefit for decentralised or modular green ammonia installations.

NX STAMI™ high-pressure technology has four operating green ammonia references, giving Stamicarbon the strongest reference list in the sub-500 t/d capacity range. Its efficient design with a simplified layout is ideal for distributed, smaller-scale projects that can be scaled up as renewable infrastructure grows. By adopting this proven technology, early movers in the green ammonia space are achieving their decarbonisation goals while positioning themselves for future expansion as electrolyser and renewable capacity grows.

Decarbonising the fertilizer value chain

Green ammonia can feed directly into a urea plant to produce low-carbon fertilizer, cutting the overall carbon footprint. Ammonia can also be converted to nitric acid and ammonium nitrate, these providing even greater potential for reducing greenhouse gas (GHG) emissions from fertilizer production.

Integrating green ammonia synthesis with downstream units can improve plant efficiency by sharing process outputs. An integrated low-carbon fertilizer complex can share the oxygen from water electrolysis, for example. These integrations save energy, lower emissions, and achieve savings in capital and operating costs through shared resources.

One example of an integrated low-carbon fertilizer plant currently under development is the FertigHy project in France. Scheduled to begin construction in 2027, the plant will produce 500,000 tonnes of low-carbon nitrogen-based fertilizers annually, powered by hydrogen sourced from renewable and low-carbon electricity. Stamicarbon’s NX STAMI™ Ammonia and NX STAMI™ Nitrates technologies will play a central role in the process, supporting low-emission ammonia synthesis and high-efficiency nitric acid production with minimal GHG emissions.

Conclusion

The development of advanced ammonia technologies – designed for a variety of feedstocks, scales, and applications – is opening the door to a new generation of low-carbon fertilizer production plants. By integrating blue and green ammonia technologies with downstream processes for urea and nitrates, it is possible to design fertilizer complexes that deliver on both economic performance and have positive climate impacts. The arrival of these technologies will shape the future of the low-carbon economy – across fertilizer, fuels, and the evolving clean energy market.