Sulphur 419 Jul-Aug 2025

17 July 2025

Sulphur: Past, Present, Possibilities

CONFERENCE REVIEW

Sulphur: Past, Present, Possibilities

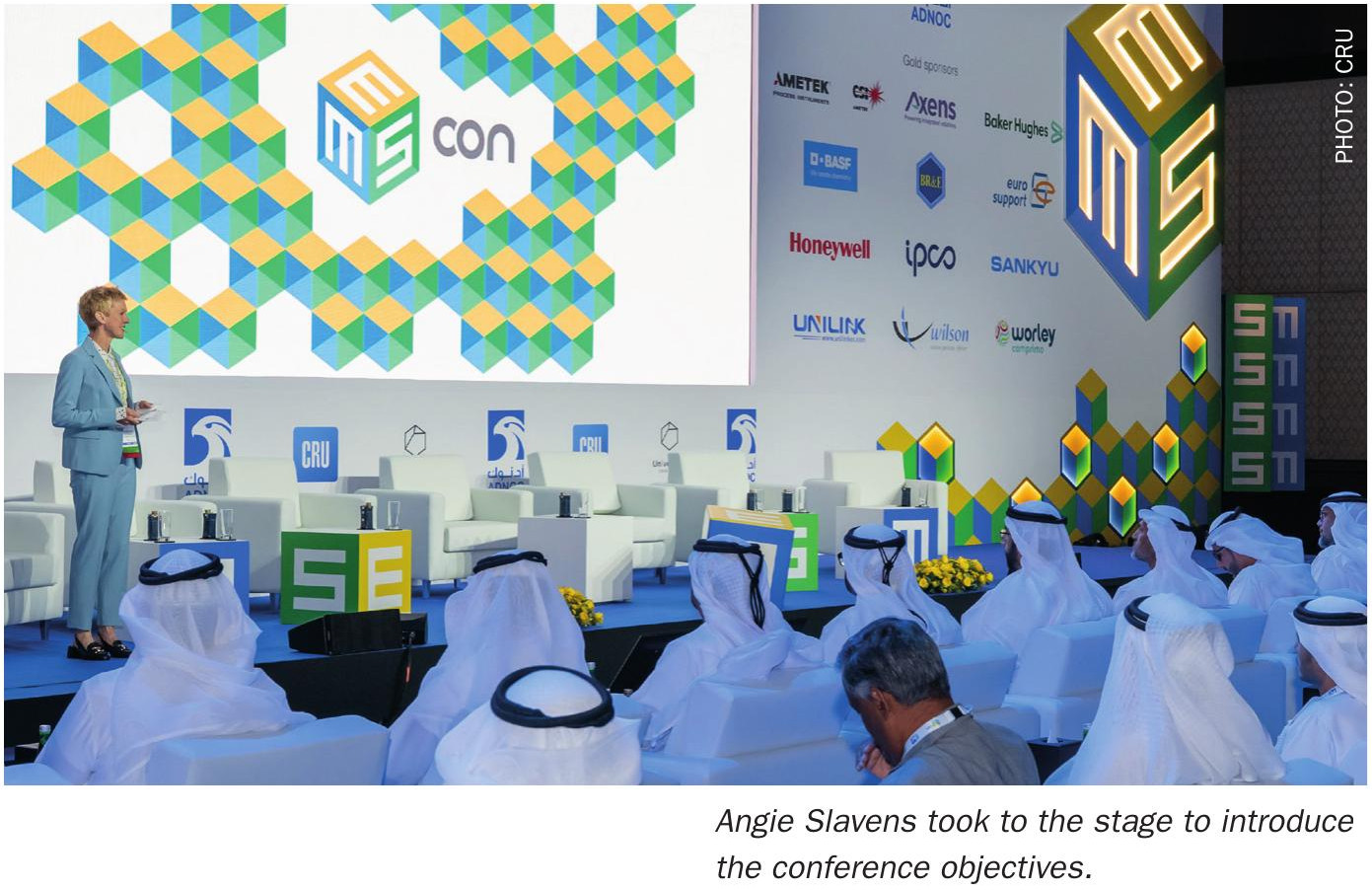

MEScon 2025, which took place in Abu Dhabi from 19-22 May 2025, provided delegates with renewed energy, new connections, and fresh ideas to apply across the sulphur value chain. From legacy learnings to frontier innovation, this year’s theme, “Past, Present, Possibilities”, remained a guiding thread throughout.

The 2025 Middle East Sulphur Conference (MEScon 2025), organised by CRU and UniverSUL Consulting and hosted by ADNOC returned to the Conrad Abu Dhabi, Etihad Towers for four days from 19 to 22 May. This year’s compelling programme celebrated sulphur’s legacy while charting a bold course toward its future. Held in the heart of the world’s largest sulphur-producing region, the event brought together global industry leaders, operators, innovators, and researchers under this year’s unifying theme: past, present, possibilities.

MEScon 2025 – Workshop day

MEScon 2025 kicked off with a high-impact Workshop Day, bringing together professionals from across the sulphur value chain for a full day of learning, collaboration, and technical exchange. Attendees had the opportunity to explore real-world challenges, cutting-edge technologies, and practical solutions across three concurrent workshops and several open forum sessions.

Workshop 1 – Steam and heating considerations in sulphur plants

Led by CSI Ametek, this deep-dive technical workshop focused on the fundamentals and field applications of steam heating systems in sulphur plants. From steam tracing to condensate return, participants gained valuable insights into system design, thermal requirements for different process streams, and lessons learned from operational upsets. Instructors shared practical examples – complete with “war stories” – that highlighted the importance of good design and proactive maintenance in avoiding corrosion, cold spots, and run-down plugging.

Workshop 2 – Navigating sulphur recovery challenges

Sulphur Experts led an engaging, choose-your-own-adventure format where the audience selected the day’s focus topics, including emissions, corrosion, plugging, and safety incidents. Real case studies sparked candid discussions, and participants were encouraged to contribute their own experiences and photos, making for an interactive and memorable session. The collaborative atmosphere fostered peer learning and helped equip attendees with practical takeaways to improve plant reliability.

Workshop 3 – Middle East Sulphur Summit

This focused workshop offered a comprehensive overview of sulphur forming technologies and handling best practices. Presentations from Enersul, IPCO, Samref, ASRL, and DuBois Chemicals highlighted granulation, pastillation, wet prilling, product quality control, remelting, dust mitigation, and acid control. The discussion-driven format ensured attendees left with a clearer understanding of emerging technologies and real-world implementation strategies.

MESconnect

At midday, MESconnect participants came together for their first in-person mentor-mentee meet-up, offering a valuable opportunity to break the ice and spark meaningful conversations that carried on throughout the week. Distinctive ribbons were distributed to help identify mentors and mentees during the event, along with MESconnect BINGO cards designed to encourage interaction through fun, goal-oriented prompts. Brief anecdotal spotlights featuring mentor–mentee stories were shared on stage throughout the conference.

MEScon annual operations roundtable

One of the long-time highlights of the conference, the operations roundtable, brought together a panel of global experts to address pressing issues across the sour gas value chain. From gas treating and sour water stripping, to sulphur recovery, tail gas treating and sulphur handling challenges, the session facilitated the sharing of operational hot topics for discussion amongst the audience.

Technical showcases

The afternoon concluded with a fast-paced series of 15-minute technical showcases, chaired by Ganank Srivastava of BR&E. Rapid-fire talks featuring breakthrough developments in gas treating, mass transfer modelling, decarbonisation strategies, SO2 control, and incinerator performance were presented.

MEScon 2025 – Day 1

MEScon 2025 officially opened its main conference with a compelling program that celebrated sulphur’s legacy while charting a bold course toward its future.

The day began with the opening ceremony, where ADNOC executives reaffirmed the UAE’s pivotal role in the global sulphur landscape. Adel Al Jaberi (SVP, ADNOC Sour Gas) welcomed attendees, followed by a keynote address from Musabbeh Al Kaabi (CEO, ADNOC Upstream), who reflected on the region’s evolution from sulphur producer to innovation pioneer. A video was shown, which showcased the history and growth of MEScon over the past 11 years. MEScon co-founder, Angie Slavens of UniverSUL Consulting, then took the stage to frame the conference’s objectives and the spirit behind this year’s theme. During her talk, Angie asked the audience to share their thoughts on the conference theme with respect to the sulphur industry which resulted in feedback highlighting the importance of the region to the future of sulphur.

The morning continued with an insightful State of the Industry session, where CRU’s Dr Peter Harrisson provided a global sulphur market overview. Presentations followed on China’s emerging demand trends (Unilink), sulphur use in Indonesia’s growing nickel and HPAL sectors (Neo Energy), and advances in sulphur science and technology from Khalifa University and other sulphur innovators, including Element 16, Sultech and Wilson International. The session highlighted new avenues for sulphur deployment in fertilizers, and energy storage – underscoring its important role in the global economy.

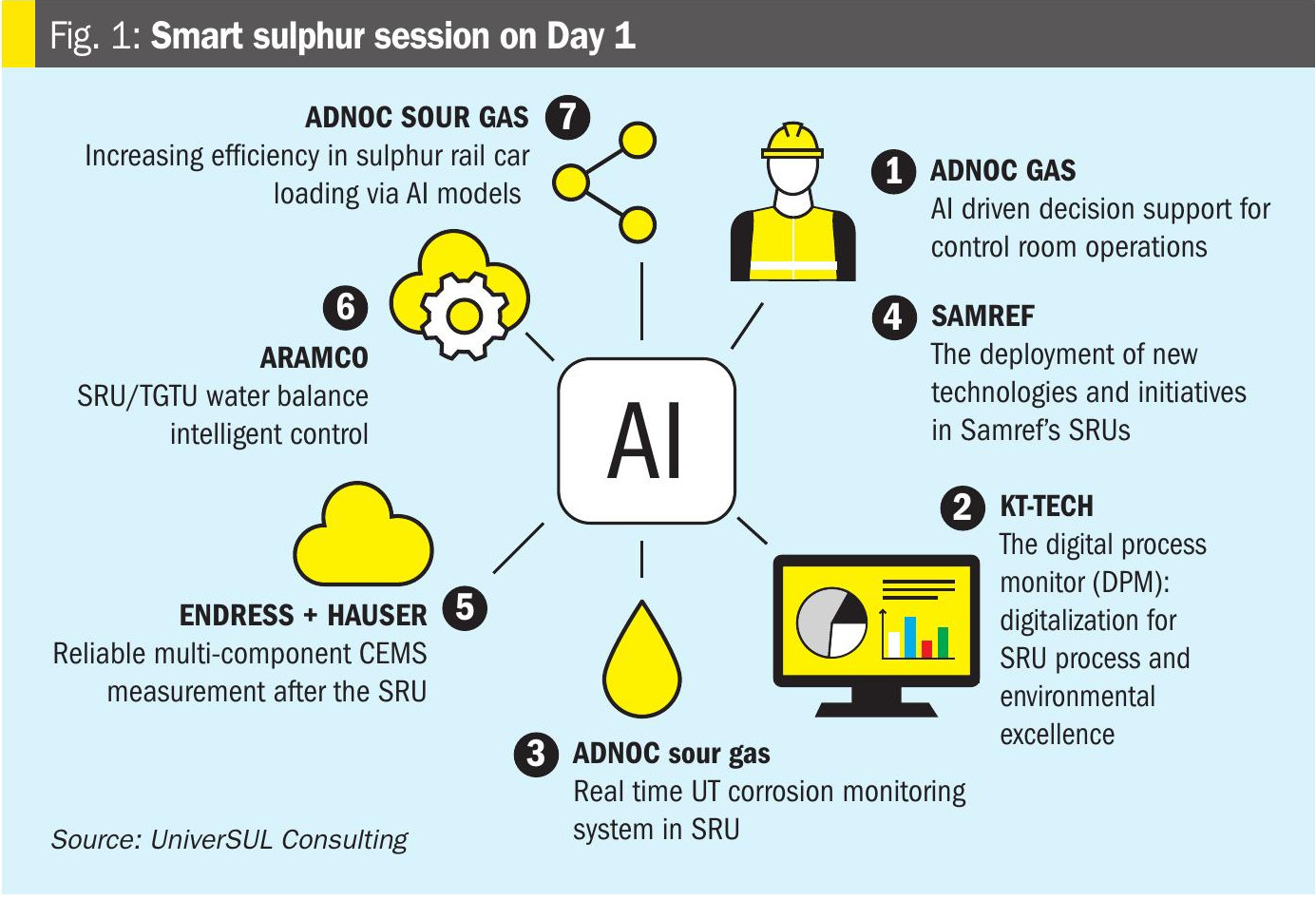

Smart sulphur: Digitalisation and AI in action

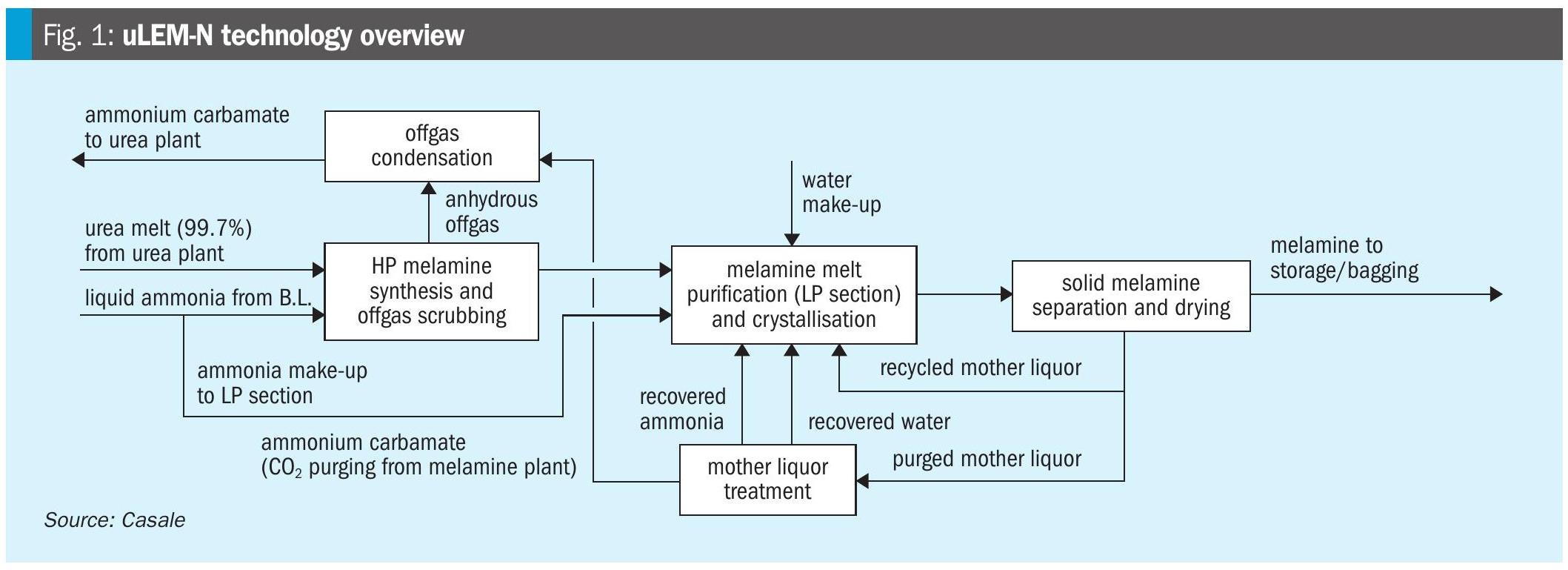

The afternoon session showcased how digital tools and AI are transforming plant performance, safety, and emissions monitoring. From real-time corrosion tracking and intelligent water balance control to AI-enhanced SRU loading and PLC upgrades, speakers from ADNOC, KT-Tech, Samref, Aramco, and others offered a look at the next frontier of operational excellence (see Fig. 1). The session concluded with an engaging panel discussion and interactive quiz to reinforce key takeaways.

MEScon 2025 – Day 2

Day 2 of MEScon 2025 continued the conference’s momentum with a dynamic program focused on sustainability, innovation, and operational excellence across the sulphur value chain. With strong engagement from operating companies and technology leaders, the day highlighted practical strategies for driving efficiency, reducing emissions, and optimising performance, solidifying MEScon’s position as the global hub for sulphur industry collaboration.

The day began with a session titled “Going green in a yellow world.” Alya Al Ali (ADNOC Sour Gas) framed the session’s objectives around sulphur’s evolving role in the energy transition and circular economy. Presentations explored innovative H2S recycling (Fluor), sustainability advancements in ultra-sour operations (ADNOC Sour Gas), decarbonisation pathways for natural gas (ADNOC Gas), and SRU optimisation strategies (Worley, NMDC, Aramco). The session concluded with a lively panel discussion, reinforcing the industry’s collective push toward greener operations.

Poster spotlights

Poster spotlights took place on Day 2 and Day 3 of the conference, complementing the conference’s technical themes. The poster sessions provided a platform for emerging research and operational case studies, as well as offering delegates the opportunity to engage directly with presenters and dive deeper into technical innovations beyond the main sessions.

Sweet solutions for sour gas

The afternoon featured the “Sweet solutions for sour gas” session, highlighting advances in sour gas production and treating. Presenters from ASRL, ADNOC Offshore, ExxonMobil, BASF, BR&E, Wood, and ADNOC Gas tackled challenges such as sulphur deposition in gas production systems, regenerable sulphur solvents, SRU integration with upstream units, and leveraging digital tools to enhance plant performance. Edward Vera Douglas from Aramco chaired the session and provided thoughtful questions and insights throughout the afternoon.

MESconnect insights

In the morning, Angie Slavens of UniverSUL Consulting and Elmo Nasato of Nasato Consulting took the stage to share insights they’ve been offering to their mentees throughout the event. Elmo encouraged attendees to embrace lifelong learning, while Angie emphasised the value of stepping outside one’s comfort zone to foster growth. Kicking off the afternoon session, Alyaziya Abdulla Alkaabi of ADNOC Sour Gas reflected on her meaningful conversations with mentors and professionals, and her contributions to the MESconnect wall.

MEScon 2025 – Day 3

MEScon 2025 concluded with a powerful finale that brought sulphur recovery, tail gas treating, and forming & handling technologies into sharp focus. As the industry looks toward a future shaped by reliability, environmental stewardship, and innovation, Day 3 delivered practical insights and technical depth to cap off a highly impactful week.

The day opened with remarks from Ali Al Hendi (ADNOC Gas) on behalf of the MEScon Technical Committee, followed by session framing from Rob Marriott (ASRL). The morning’s technical block featured field-tested lessons from commissioning, start-up, and optimisation efforts at major facilities including Aramco Jazan and Petronas Melaka. Experts from Ametek, CSI Ametek, NCL, and Axens provided insights into gas-phase chemistry, sealing technologies, and novel catalyst ideas in tail gas treating units.

A key highlight was the session’s panel discussion, which invited open dialogue between presenters and the audience – reinforcing MEScon’s mission to create a collaborative space for peer exchange in the world’s largest sulphur-producing region.

Shaping sulphur: Forming and handling

In the afternoon, the focus shifted to solid sulphur logistics with a session led by Sultan Alshamsi (ADNOC Gas). Aramco, IPCO, and ADNOC Sour Gas shared strategies to enhance reliability and performance in sulphur solidification. The session covered why and how to solidify sulphur, best practices in sulphur handling, and emerging dust and spill control solutions. Samref and DuBois Chemicals presented a compelling case study on overcoming persistent dust challenges, while ADNOC Gas rounded out the session with insights on advanced mitigation strategies.

MEScon continues to be a place where global collaboration, regional leadership, and technical excellence converge to shape the future of the sulphur industry.