Sulphur 392 Jan-Feb 2021

31 January 2021

Is sulphur the missing ingredient?

TSI REVIEW

Is sulphur the missing ingredient?

Ron Olson of The Sulphur Institute considers sulphur’s important role in plant health.

Sulphur is demanding more attention these days because the amount provided free of charge, via acid rain and other sources, is becoming less. There have been large changes in the global and regional sulphur dioxide (SO2 ) emissions over the last few decades. At the same time, increasing yield trends have increased sulphur removal by the crop. A bushel of corn removes 0.08 lb (36g) of sulphur in the grain and 0.09 lb (41g) in the stalk or 0.17 lb (77g) total. That means 200 bushels of corn takes up 34 lb/acre of sulphur, or 38 kg/hectare. In terms of actual plant available sulphate (SO4 ) that is 102 lbs of SO4 per acre (114 kg/ha). By understanding the nature of sulphur and its role in plant growth, farmers around the world can ensure their crops are never starved for this essential nutrient.

Characterised by its bright yellow colour, sulphur can take many forms or oxidation states; elemental sulphur ions, mineral sulphate or sulphide gas. This is unique to sulphur, for example potassium always remains a potassium ion as it passes through soil microbes and plants. Soil microbes are essential for converting organic sulphur (not available to the plant) into sulphate which is available to the plants. Ninety-five percent of all sulphur found in the soil is tied up in its organic matter.

Sulphur’s role in plants

Plant dry matter contains 0.2-0.5% sulphur (about the same percentage as phosphorus). In crop production, sulphur’s most critical job is helping produce protein molecules and amino acids, which are required to produce chlorophyll, lignin, and pectin. To do that, it assists in photosynthesis, the process in which plants convert sunlight into chemical energy.

In one aspect of protein production, sulphur helps metabolise nitrogen. If a plant tissue test reveals a sulphur deficiency, it probably will show a nitrogen deficiency too. Both are structure-building components, so sulphur (like nitrogen) is required early in the season. The plant needs sulphur to build the factory that will produce the seed or fruit.

Besides showing a pale green colour, sulphur deficiency results in stunted growth. Anything that retards growth delays maturity. Sulphur-deficient corn will delay tasseling and pollination and matures later. Plants become inefficient, producing less growth per day. Below the ground, sulphur deficiency shows up in a slow-growing, smaller, inefficient root system.

The pale green colouration, stunted growth and delayed maturity mimic the symptoms of nitrogen deficiency. The main difference is that nitrogen deficiency shows up in the bottom leaves of the plant, but sulphur deficiency shows up in the newer growth; the top leaves or whorl. Unlike nitrogen, sulphur is not mobile in the plant, so the plant cannot mobilise sulphur from older portions and move it to newer ones.

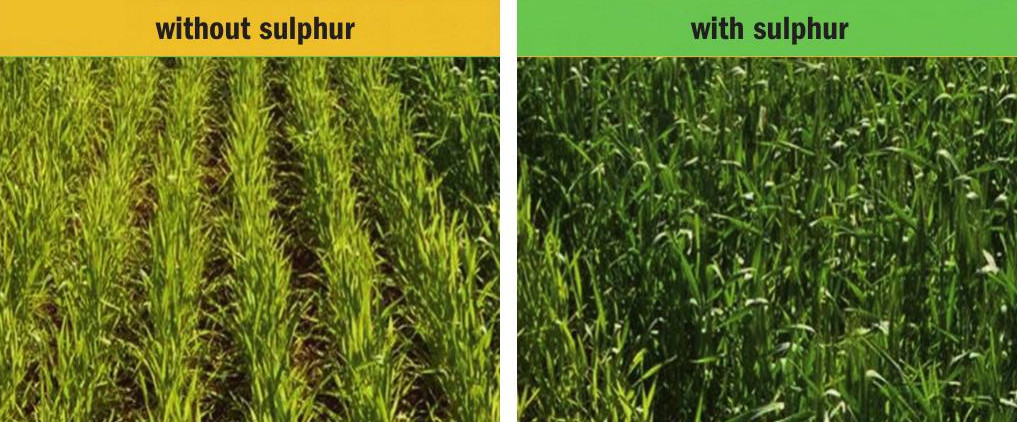

Figure 2 shows young corn plants growing with and without sulphur. On the left the plants are growing well, showing good green colour and vigour. On the right the plants are a pale green colour, lacking vigour – the health of these plants has been significantly impacted by the lack of sulphur. In this example the lack of sulphur is slowing down photosynthesis and root development. NPK fertilizer application was the same for both plots. Only sulphur was missing.

Figure 3 shows a wheat crop on the left severely impacted by the lack of sulphur. Again the NPK fertilizer application was the same for both plots. Only sulphur was missing, resulting in reduced photosynthesis and delayed and reduced plant development.

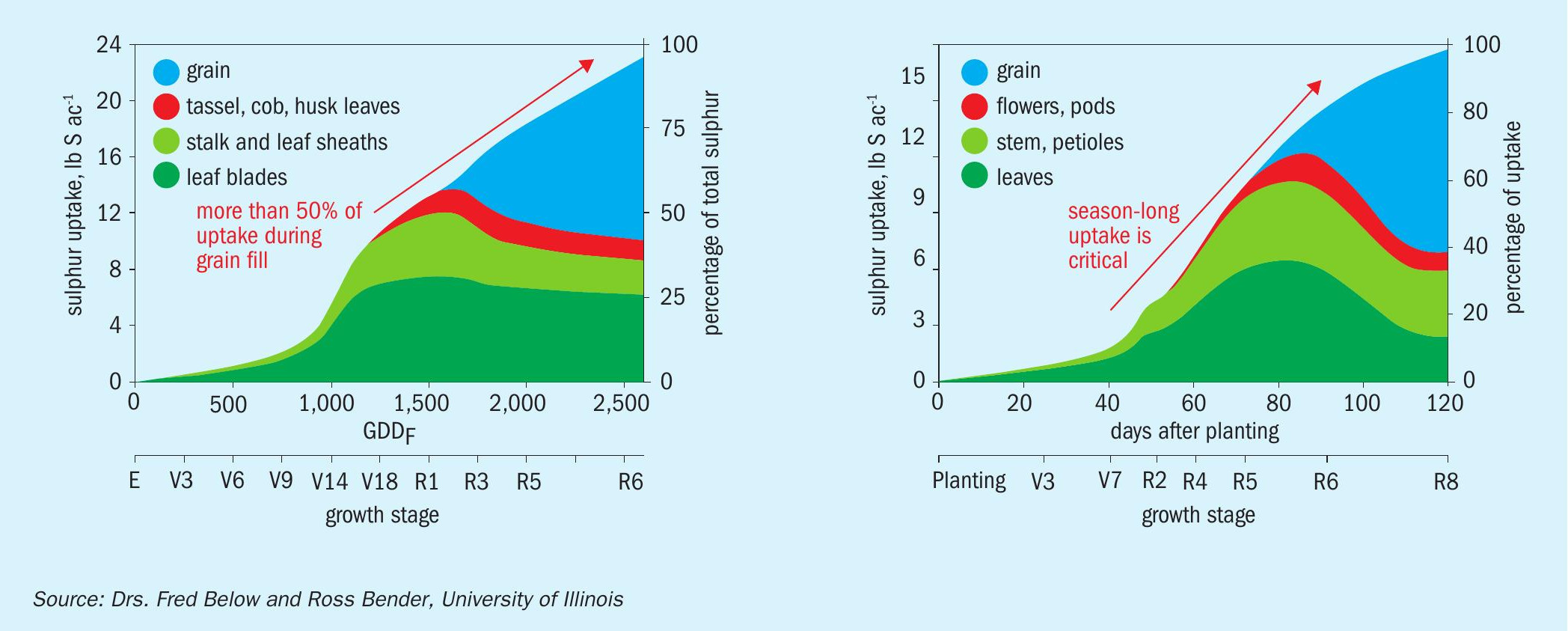

Figure 4 shows corn and soybean sulphur usage. A corn plant uses 52% of all seasonal sulphur needs post-tassel. A soybean plant uses over 85% of all season sulphur needs during its reproductive stages.This confirms that corn and soybeans need a full season supply of sulphur to meet the crop’s needs during critical growth periods.

Sulphur uptake

Aside from a small amount of sulphur in rainfall, or foliar feeding of sulphur fertilizer, the main form of sulphur that plants can take up is sulphate. The large amounts of sulphur needed to produce crops must be taken up by the root system in order to meet the plant’s needs. The amount of sulphur consumed by the plant depends on how much of the nutrient the roots contact as they grow through the soil. In the soil, sulphate moves toward the roots by diffusion and mass flow. In diffusion, sulphate moves from a more concentrated area to a less concentrated area – similar to food colour dispersing in water.

In mass flow, water containing sulphate is pulled to the plant roots. Transpiration through the plant draws more water out of the soil, bringing sulphate with it.

The sulphur cycle

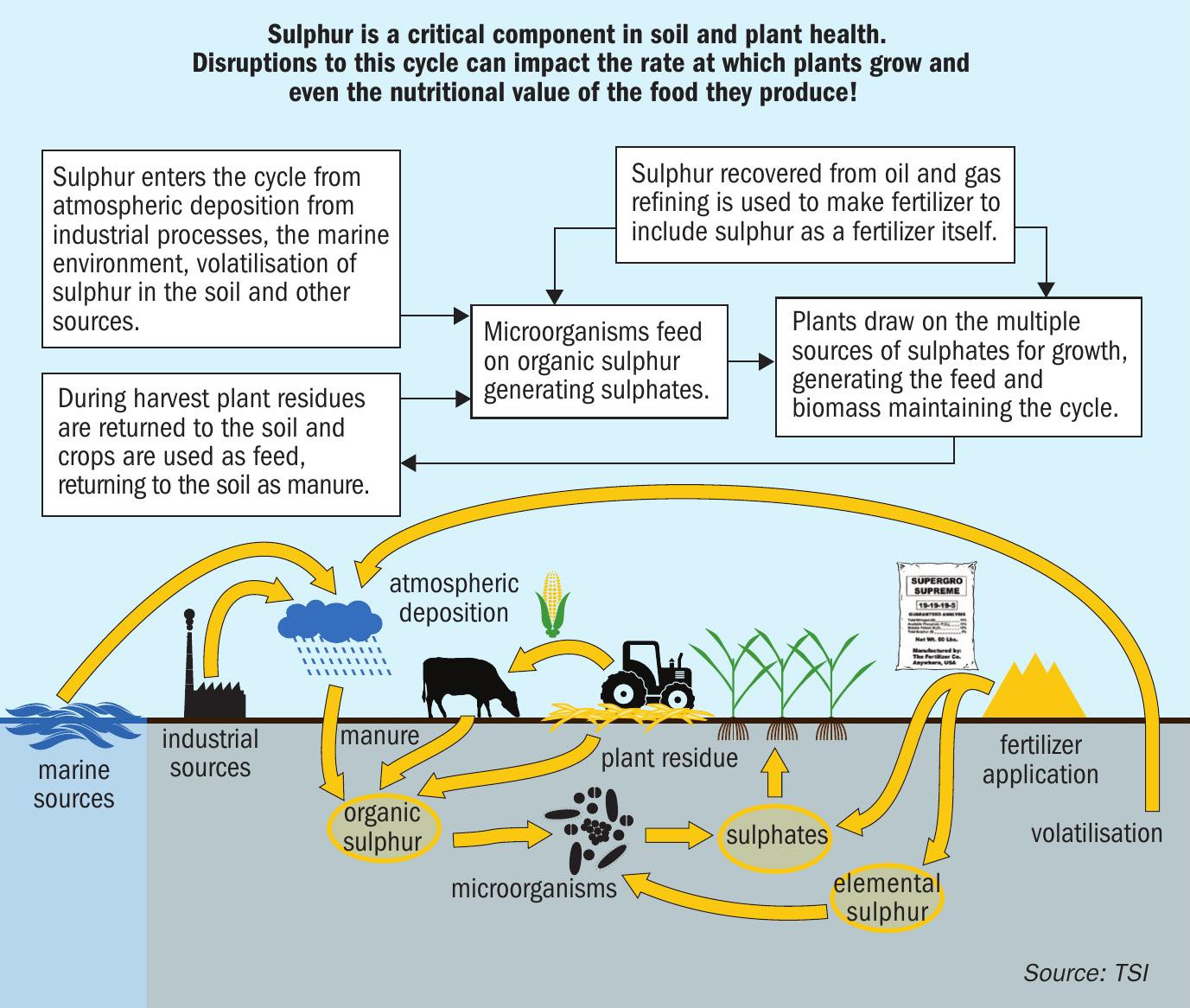

In the soil, there are three forms of sulphur: sulphide gas, sulphide minerals and elemental sulphur, which need to be oxidised into sulphate for plants to use. All of these sources go through oxidation. Like nitrogen and phosphorus, sulphur follows a cycle in which it moves from the organic form, which plants cannot use, to the inorganic form, which they can take up and return again.

Some microbes and plants immobilise sulphur; others mineralise (or oxidise) it into sulphate. Mineralisation and immobilisation go on at the same time. The sulphur cycle is shown in Figure 5: it shows how sulphur gets to the crop; the forms of sulphur and what happens to the sulphur, like plant uptake, leaching and volatilisation. It is key to note that sulphur is lost from the soil in much the same way as nitrogen is. Sulphur is absorbed as the sulphate ion and can also enter plants as sulphur dioxide gas. Sulphur comes into soil solution via the mineralisation of organic matter. Low organic matter soil can be deficient, as 95% of sulphur found in the soil is tied up in the organic matter. Each 1% of organic matter can supply 3-5 lbs/1.4-2.3 kg of sulphur via mineralisation.

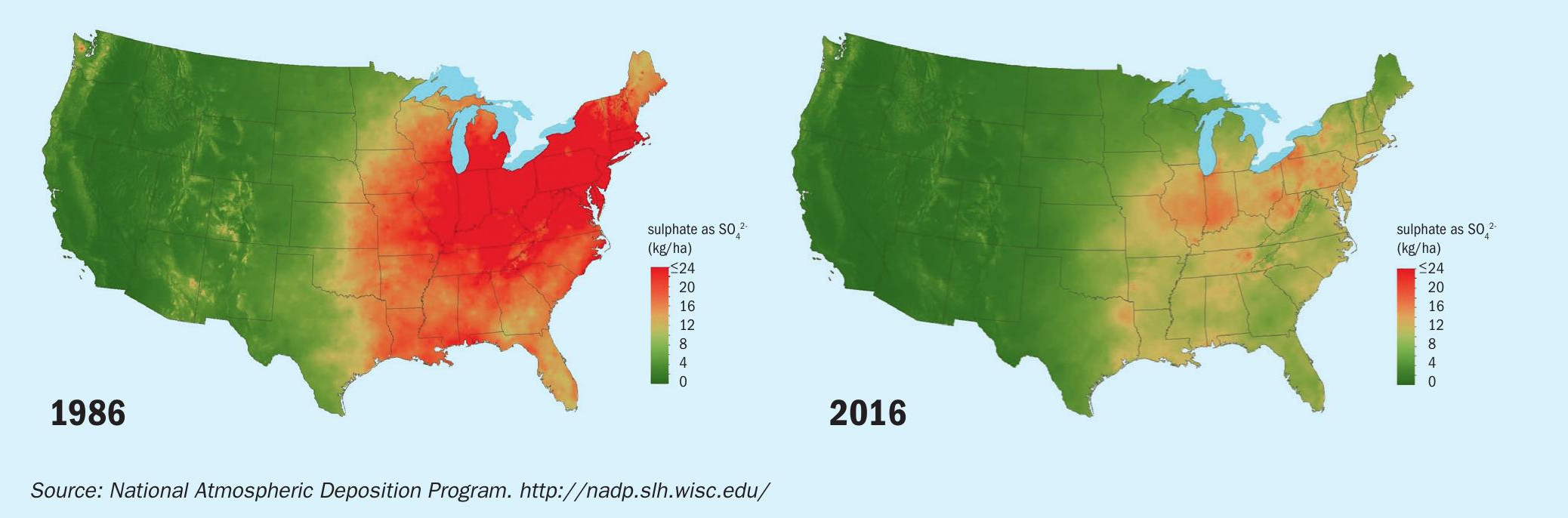

Sulphur deficiencies in soils are increasing and sulphur fertilizer has become more important because higher crop yields are removing more sulphur.At the same time, crops are receving less sulphur from the air due to the decreased use of high sulphur coal and removal of sulphur dioxide from stack gases (up to 25-30 lbs/acre or 25-35 kg/hectare of sulphur used to be deposited free in industrialised countries via acid rain). Figure 6 shows the sulphate ion wet deposition in the US for 1986 being greater than 25 kg/ha compared to 4-8 kg/ha in 2016.This is an 80%+ reduction in sulphate ion deposition and is similar to reductions in Europe and other parts of the globe.

Sulphur as a nutrient

Important factors to remember about sulphur as an essential plant nutrient include:

- Sulphur deficiencies are more common due to higher yields and less sulphur dioxide gases being emitted from stacks.

- Sulphate (SO4 ) is highly mobile in the soil and can leach like nitrogen.

- Most soils typically cannot supply adequate sulphur nutrition through mineralisation.

- Low mineralisation growing seasons (cooler and wetter than normal) can increase sulphur deficiency.

- Corn takes up 52% of its sulphate needs after tasseling and pollination and soybeans take up 85% of its sulphate needs during flowering and pod fill.

- There is a strong relationship between nitrogen and sulphur since both are associated with chlorophyll formation and both are constituents of proteins.

Approximately 54% of all recovered sulphur produced globally is used in agricultural fertilizer production to produce food to feed a hungry world. The science of sulphur has not changed. Sulphur will continue to be an essential plant nutrient supporting the changes coming from the Internet of Things, digitalisation of agriculture, machine learning, artificial intelligence, and big data. Here are nine areas that represent some of these trends:

1. Smart fertilizers were listed as number 5 out of the Top 10 Emerging Technologies at the 2019 World Economic Forum.

2. The global implementation of the 4R Nutrient Stewardship Principles: Right Product, Right Rate, Right Time, Right Place.

3. Emerging landscape of biostimulant/ biological products

4. Soil health, cover crops, reduced tillage, and regenerative agriculture

5. Biotechnology – as new hybrids and varieties that can deliver higher protein content sulphur will matter and play a key role

6. Sulphur-enhanced fertilizers and direct application of sulphuric acid (H2 SO4 )

7. Precision agriculture tools that will create algorithms to deliver targeted fertilizer applications down to many sub-fields within a field that will drive yields, efficiency, profitability, and sustainability.

8. Nanotechnology to make fertilizers more efficient

9. Greater use of robots in agriculture

As we study these trends, TSI is going to examine how sulphur impacts or is impacted by each one. The need for sulphur by global crop production is significant and looks to create positive benefits for the Sulphur industry. The Sulphur Institute is well positioned to help its members move into this exciting future.

References