Kore seeks new owner for Kola potash project

The Kola potash project is up for sale and has started early works in the Republic of Congo.

The Kola potash project is up for sale and has started early works in the Republic of Congo.

EU Executive Vice‑President Stéphane Séjourné published an op‑ed calling for tying European public funding to companies that commit a substantial share of production to the EU. The piece, syndicated in several major outlets including Handelsblatt on 2 February 2026, was presented as a call signed by 1,141 European business and union leaders. “Whenever European public […]

The Saudi Arabian Mining Company (Ma’aden) says that the Ministry of Energy has approved the allocation of feedstock for its fourth phosphate project. This project aims to produce approximately 1.1 million t/a of ammonia and increase the production of phosphate and specialty fertilizers by about 2.5 million t/a, raising the company’s total production capacity to nearly 12 million t/a. This will further solidify Ma’aden’s position as one of the world’s largest producers of phosphate fertilizers, according to a company statement. Ma’aden will now commence engineering studies and obtain the necessary approvals.

Syria restarted a phosphate production site in Homs province after a decade-long shutdown, according to local media reports 25 November. The washing and drying facility is part of Syria’s Al-Sharqiya mine. The Syrian government has indicated that it plans to increase its presence in global phosphates market as part of efforts to support the country's economy.

Romanian oil and gas group OMV Petrom has commissioned a new sulphur recovery unit at its Petrobrazi refinery, near the southern city of Ploiesti. Development work on the new SRU began in 2023, and represents the second at the site, treating acid gas produced during the refining process. The euro 45 million investment is part of euro 2 billion of improvements that have been made over the past 20 years as part of the company’s strategy to modernise its refining capabilities, aiming to reduce environmental impact. Last year, the company said it would invest around euro 750 million to build several sustainable fuel plants at the refinery, which are expected to become operational in 2028.

Syria’s Geological and Mineral Resources Authority has signed an agreement with Teryaq, a subsidiary of Serbia’s Exlixir Group, aimed at exporting 1.5 million t/a of phosphate by the end of 2026. The agreement marks a significant step in Syria’s efforts to expand international partnerships and optimise its mineral resources for economic gain. Elixir Group owns the largest phosphoric acid plant in Europe and operates three fertilizer plants in Serbia.

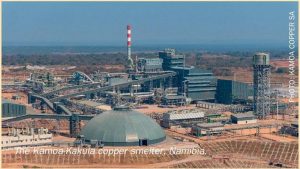

Ivanhoe Mines says that the first copper anodes were produced by Kamoa-Kakula’s 500,000 t/a direct-to-blister copper smelter on December 29, 2025, approximately five weeks after the commencement of the smelter’s heat-up and one week after the first feed of concentrate.

Three German subsidiaries of the Belgian chemical group DOMO Chemicals have filed for insolvency, following weak demand in the European chemicals sector, high energy costs and a significant increase in imports of polyamide resins from outside the European Union, in particular from China. Court appointed administrator Prof. Lucas F. Flöther said that day-to-day operations would continue for the time being. Around 585 employees are affected across the three companies; DOMO Chemicals GmbH and DOMO Caproleuna GmbH in Leuna and DOMO Engineering Plastics GmbH in Premnitz.

Mosaic has started activities to idle single super phosphate (SSP) production at its Fospar and Araxá facilities in Brazil due to the recent sharp increase in sulphur prices, the company said 16 December. The company said it has also suspended future purchases of sulphur, and it may review these decisions after 30 days. Sulphur spot prices in Brazil were assessed by CRU at $515/t c.fr at the time, representing the highest level since June 2022, and a staggering 180% increase from the figure of $182/t c.fr at the start of 2025. Prices for SSP, however, have been relatively stable, with only slight increases in recent weeks. CRU's assessment for 18-20% SSP was at $200-245/t c.fr Brazil in December, up from $190-240/t in November, though it remains below the $230-265/t of June.

Sulphur prices have risen rapidly in recent months as the market moves into a period of deficit which is likely to last until 2028.