Nitrogen+Syngas

31 January 2016

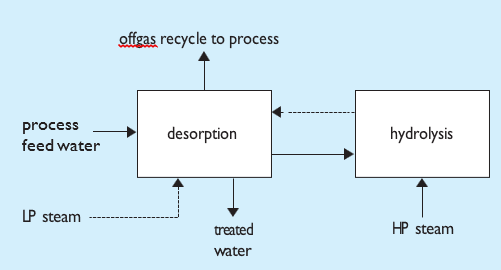

Problem No. 34: Reuse of off-spec waste

The waste water treatment section in a urea plant processes the water containing NH3-CO2 and urea from the vacuum system in the evaporation section. It delivers an almost NH3-CO2-urea-free purified process condensate that is suitable for reuse outside the urea plant. This process condensate can be discharged with a content of 1 ppm of urea and 1 ppm of ammonia. With such negligible values of pollutants, three targets are simultaneously realised which contribute to reducing the cost of urea: specific consumption of ammonia is decreased, environmental pollution is reduced and the possibility to reuse the process water is guaranteed for several technical purposes.

Mr Niraj Nimje of RCF Thal in India kicks off this Round Table discussion with a practical and troublesome problem: In our Saipem urea plant, after the booster ejector and condenser washing in the vacuum section, we are experiencing problems with the concentration in the waste water section feed tank and the off grade condensate is wasted as effluent. What methods can be used to treat this off-spec condensate to make it BFW grade? I have heard of using a polishing unit for such cases but what is the maximum concentration that is permitted? What are the exact arrangements required to ensure quality?

Mr Prem Baboo from NFL company in India shares his experience: We have carried out the following modifications to the vacuum sections:

- crown flushing of 2nd stage vacuum separator (cone flushing) with 99.7% urea solution to minimise the water load and to minimise prilling diversion;

- condenser flushing with waste water (waste water to distillation), a 2″ line taken from the distillation tower feed pump for flushing and to minimise the water load in the waste water section;

- water monitoring and water balance in each shift.

We receive waste in the DM plant containing 1.0 ppm urea and 2-3 ppm ammonia and this is suitable as DM water. We maintain the following parameters:

- distillation pressure top 1.8 kg/cm2g and a temperature of 112°C; bottom temperature of 132°C; low pressure steam to distillation flow is 11.0 t/h;

- waste water flow about 80-82 m3/h at 3,500 t/d load;

- hydrolyser pressure 34 kg/cm2g and temp 232°C; steam flow to hydrolyser about 5.0 t/h;

- waste water analysis 5.5 to 6.0 wt-% ammonia and 0.9 to 1.0 wt-% urea.

Mr Nagaraju from Notore Chemical Industries in Nigeria asks a question: Does the waste water from the 2nd desorber contain such high levels of ammonia and urea? In our plant it used to be around 100 ppm urea and 50 ppm ammonia.

Prem replies: This high concentration of ammonia and urea cannot be taken in demi-water, it means your hydrolyser is not working properly, the hydrolyser outlet urea should be less than 1-2 ppm. Please clarify your hydrolyser pressure, temperature and desorber temperature etc.

Mr Kashif Naseem from SABIC in Saudi Arabia shares his idea and asks a question: I agree with Prem that waste water with an ammonia and urea concentration of 1~3 ppm is acceptable for use as BFW after passing through a polisher.

Like Prem you are using this in boilers as boiler feed water, have you observed any corrosion in the boiler or steam line and what is the status of ammonia and urea in CBD?

Niraj provides further information: Prem, we perform the same activities that you mentioned and we are getting BFW quality water without any polishing unit. Our hydrolyser and distillation units are working fine at 25 kg/cm2 and 1.8-2 kg/cm2 respectively, but after crown washing, condenser booster ejector washing, or during any upset, the waste water tank concentration changes (temporarily) and off-spec wastewater is generated.

During such situations we increase the steam to the hydrolyser and distillation column. After a revamp our waste water load increased from 40 to 50 m3/h so it is sometimes difficult to maintain the quality of water generated after performing activities mentioned. As we don’t have any polishing unit, we are looking forward to it, and want to convert even small quantities of off spec waste water into boiler feed water.

Prem replies: For BFW water ammonia is not a problem because the ammonia is added to raise the pH of the BFW. Only urea is a problem due to a problem of your hydrolyser. Hydrolysis is a function of temperature and you cannot raise the temperature beyond 223°C at a pressure of 25 kg/cm2 with a revamp. You should revamp this section by either increasing the residence time or raising the pressure.

Please note the residence time of your hydrolyser has been reduced after the revamp.

Mr Mang Tãn Phong from Petro Vietnam Ca Mau fertilizer company in Vietnam raises another question: Our plant uses Saipem technology for the urea synthesis and TEC technology for the fluid bed granulation. Our MMU section didn’t work well so we decided to stop operating the MMU section and feed formaldehyde directly to the pump suction line. In this case our waste water after treatment still contains formaldehyde (more than 500 ppm). The parameters at the top and bottom of distillation are, respectively 4.2 bar and 130°C, 4.7 bar and 157°C. The condition in the hydrolyser is 31 bar and 230°C. How does formaldehyde at concentrations above 500ppm affect the BFW, and how can it be treated?

Mr Mark Brouwer from UreaKnowHow.com in the Netherlands replies: Formaldehyde will be converted into formic acid in the hydrolyser. Depending on how the purified process condensate is reused, additional measures may be needed to avoid corrosion problems. For example reuse as cooling water make up may be possible without further treatment, while reusing it as boiler feed water for 40 bar steam will require further purification. One could send the purified process condensate to the inlet of the demi water section where the carbon filter and ion bed exchangers will take care of the formic acid.

Mr Majid Mohammadian from OCI in the Netherlands shares his idea: If you are injecting the formaldehyde as an anti-caking agent for the granulation/prilling section, it should normally be injected to the discharge of P8 and not P6, in this case you will have much less formaldehyde in your waste water treatment section. Can you clarify why you are injecting it to P6?

Mr Nikhil Kamat from India asks a question: What should the ammonia content and urea content in the treated waste water be so that it can be used as boiler feed water?

Prem replies: In our plant, the treated water from the distillation tower contains about 2-3 ppm ammonia and 0.5-0.8 ppm urea. This treated water is sent directly to the DM plant (cation/anion/ mixed bed) and then used as BFW. The turbine condensate and steam condensate are sent to the DM plant i.e. cation unit for iron removal only and then used for BFW

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |