Nitrogen+Syngas

31 December 2015

Problem No. 33: Excessive amount of carbamate solution from recirculation section

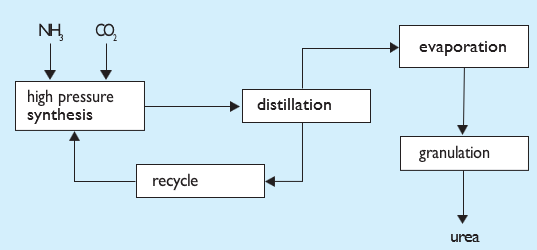

The recirculation or distillation section in a urea plant where unconverted carbamate is separated from the urea/water mixture is a critical section of a urea plant that influences the overall performance of the plant. Too much carbamate solution recycle back to the synthesis section will increase the amount of water in the synthesis and will negatively influence the reactor conversion figures. Fouling in the recirculation section can sometimes cause these operational problems, but how can fouling be identified as the root cause of a problem?

Mr Janusz Mac´kowski of ZCh “Police” in Poland kicks starts the Round Table discussion with the following problem: We have quite an old Stamicarbon plant designed in 1976. The gas outlet pipe from the low pressure rectifying column is connected to the gas outlet pipe from the first desorber of the waste water treatment section and together these are connected to the low pressure carbamate condenser (LPCC). There is no reflux condenser. We have a problem with an excessive amount of carbamate solution in the LP carbamate condenser level tank, which leads to overflowing of the level tank. Is it possible (as a result of some kind of equipment damage) that:

- an additional amount of solution goes through the gas pipe from the rectifying column to the LP carbamate condenser?

- and/or an additional amount of solution goes through the gas pipe from the waste water treatment section to the LP carbamate condenser?

Has anyone experienced such a problem?

Mr Mark Brouwer of UreaKnowHow.com in the Netherlands shares his experience: Yes, I have seen excessive liquid entrainment from the low pressure rectifier to the LPCC due to fouling (iron oxide scaling) of the holes in the trays in the rectifier. What is the urea content in the carbamate recycle?

Janusz replies: We don’t have trays in the rectifying column, we have a bed with rings. Some (not all) of the carbamate solution samples show a very high urea content, up to 29 wt-%.

Mark responds: But you do have a liquid divider on top of the bed – that is what I meant by trays.

29 wt% is a sure indication of entrainment from the rectifier. Do you have a tangential inlet or sprayer for the liquid inlet of the rectifier?

Mr Akbar A of Safco in Saudi Arabia shares his view: We have also experienced the same problem, but with a new Stamicarbon plant where a separate reflux condenser was installed for the desorber column. At the moment when the level of the LPCC level tank shoots up, collect a sample and analyse it for urea. If you find a high urea content, it will be clear that urea solution carryover is occurring from the LP rectifier column only. 29 wt-% urea is too high and may affect the synthesis conditions and HP scrubber, as well as the HPCC equipment.

In a new Stamicarbon urea plant this problem can be solved temporarily by increasing the pressure in the rectifier, but in your case you don’t have a separate condenser for the desorber so this increase in pressure will disturb the desorber performance.

Do you have orifice plugs in the tubes at the bottom of the rectifier? If the internal diameter of these orifice pugs has reduced, that can also cause carry over.

Janusz answers: Yes, we do have something that could be called a liquid divider over the bed. We don’t have a tangential inlet. And we don’t have orifice plugs in the heater tubes.

Mr Easa Norozipour of Khorasan Petrochemical Company in Iran shares his experiences: We have experienced this problem twice in the low pressure rectifier column. After opening the column we saw that the packing bed was choked with corrosion material. Another one was choked in the heater tubes. The failure of the level transmitter in the rectifier tower can also be another cause.

Mr Kashif Naseem of SABIC in Saudi Arabia contributes with his experiences: Possible sources for this is choking of the orifice plugs in the bottom of the rectifying column circulation heater and the packing.

Mr Akbar Ali of SABIC/Safco in Saudi Arabia joins the discussion: For a better understanding of the phenomenon of carry over due to blockage in the top liquid divider and bottom orifice plug, see pictures on previous page, captured after opening the rectifier column following the same problem of solution carry over. After removing these bottlenecks the plant conditions improved.

Janusz replies: In my case the heater was clean but the packing support plate was almost completely clogged with corrosion products – see picture above.

Mr Muhammad Farooq of SABIC/Safco in Saudi Arabia agrees with Mark: I agree with Mark’s observation about the rectifying column. However, a higher recycle rate can be reduced gradually by closing the reactor off gases to the low pressure section provided that the synthesis pressure is in a controllable range, in this scenario the control valve opening should be checked. Although it is not the cause of urea carryover, it may reduce the intensity of the higher recycle rate.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |