Nitrogen+Syngas 331 Sept-Oct 2014

31 October 2014

Problem No. 26: How to find a leak in a liner

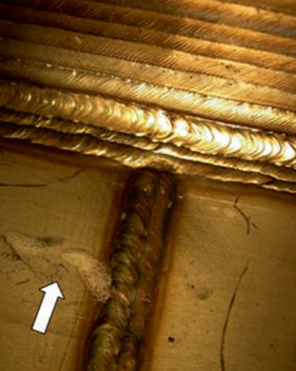

High pressure urea synthesis equipment consists of a carbon steel pressure bearing wall, which is protected by a protective layer. Carbamate can corrode carbon steel with a rate of 1000 mm per year. The protective layer can be a loose liner or weld overlay. Loose liners require an accurate and reliable leak detection system in order identify in time that there is a leak in the liner. Once a leak is confirmed, the only advice is to stop the plant and repair the leak. But how can the leak be located? It is not always easy to find a small leak. There are several methods: helium leak test, air soap test, ammonia leak test, etc, but which method works best for small leaks?

Mr Mark Brouwer of UreaKnowHow.com in the Netherlands starts the Round Table discussion: A leak in a liner is identified by a leak detection system. According to your experiences what are the best ways to find the precise location of the leak?

Mr Chris Boyda of Agrium Inc. in Canada shares his experiences: We recently experienced a liner leak in our HP stripper. Initially, we tried to use a pressurised ammonia test to locate the leak. This test required putting a small amount of pure ammonia in between the liner and the vessel shell and controlling the pressure to ~5 psig. On the vessel interior we tried to locate the leak by using ammonia sensitive paper (blue print paper), and ammonia sensitive spray.

Due to the very small size of the leak, this test failed numerous times. At this point we tried using helium. The helium test was set up where a vacuum pump was used to apply a vacuum to the leak detection ports, and small amounts of helium were swept over all internal welds until we detected helium on the gas chromatograph on the vacuum side. This helium method was very successful in helping to locate the leak location and did not risk over-pressuring the cavity between the liner and the shell.

Mr Srivatstava Prabhat of Tata Chemicals Limited in India shares his experiences: Leak detection in HP equipment liners especially in a stripper is a little tricky compared to a reactor because some of the weep holes connected to the liner are independent. In the case of the reactor all weep holes are interconnected. For identification of a leak in the liner we have used a method in which we pressurised the shell side with low pressure steam maintaining a pressure of 0.5 kg/cm2 (selecting a weep hole close to the leak point.) Then, by touching the inner surface we were able to detect heat in the area of the leak. By pressurising the shell side with air, maintaining a pressure of 0.5 kg/cm2 with the same weep hole, and applying a rich soap solution in the selected area from the inside, with the help of an air bubble leak test method the leak source point can be identified. Another method is the helium leak test method. This is a good method but it needs time. Pressurising with ammonia in my opinion is not a suitable method for identification of a leak because of the safety risks for the person entering the vessel. In addition, welding is difficult in the presence of ammonia so removal of ammonia is also important. If the leak is near to a single point liner ammonia removal can be difficult and time consuming. If someone has a more suitable method, please share as this is very useful and almost all fertilizer plants face this problem.

Mark asks for some clarifications: What do you mean by a single point liner, do you mean that the liner compartment contains only one leak detection hole? Normally each liner compartment has two leak detection holes so that flushing is possible with a gas from one hole to the other. This is normally valid for all kind of HP equipment. Please elaborate on your statement that a stripper is a more tricky job than a reactor. Please confirm that with the shell side you mean the area between the liner and the carbon steel pressure wall.

Mr Girish Prakash of Tata Chemicals Limited in India provides some answers: Probably, what Prabhat means is that for a Saipem reactor and stripper the weep hole arrangement is slightly different. Also there are a few weep holes, which are not connected to others.

The helium leak test has proved to be a good alternative in our experience.

Mark provides further information: Stamicarbon’s advises (see E-newsletter dated 24 January 2011) that there are two recommended methods for finding a leak: the bubble test and the ammonia leakage test.

In cases where the leak is large enough, a bubble test is an appropriate method. The detectable leak rate using the bubble method is in the range of 10-3 std.cc/s (standard cubic centimeters per second). For smaller leaks an ammonia leak test is advised. Ammonia is introduced behind the liner with a maximum pressure of 0.03 barg. After a period of 8 to 10 hours leaks with a leak rate as small as 0.02 to 0.03 cc/hr becomes detectable. The detectable leak rate is about 1000 times better compared to the air bubble test; 10-6 std.cc/s.

Srivatstava replies to the earlier questions: Principally weep holes of all HP equipment items must be interconnected at at least one point. But in our stripper I have checked many times and found that some of the weep holes in the stripper are independent although they are in the minority.

The reason I say that strippers are more tricky it is more difficult in the bottom portion specially if the leak occurs from the joint of exchanger tube sheet and bottom dome of stripper shell. Yes, the shell side means the area between the liner and the carbon steel pressure wall.

Mr Amrit Ramnanan of IPSL in Trinidad and Tobago shares his experiences: In the TEC ACES HP synthesis loop equipment the following techniques are employed to determine the location of a liner leak after the leak detection system has flagged a problem:

- review equipment drawing for liner welds associated with detection hole;

- Use dye penetrant inspection of liner weld(s). What else can be done if the leak is still not found?

Mr Son Nguyen of PVFCCO in Viet Nam replies: You can apply steam to the weep holes and then measure the conductivity as condensate comes out at the outlet to determine fairly accurately where the leak is.

Mark replies: The disadvantage of putting steam or condensate behind the liner is that one can introduce stress corrosion cracking risks to the carbon steel. Several times severe cracks have been found in the carbon steel pressure wall on the inside (liner side) and in all these cases the end user followed the practice of putting steam or condensate behind the liner.

Son responds: Am I right in saying that stress corrosion will only take place if you cannot maintain a continuous flow of steam or condensate?

Mark replies: SCC is caused by a combination of chemical substances and metals at certain conditions.

For example, nitrates with carbon steel or chlorides with stainless steel at certain temperatures and stresses.

Also carbonates with carbon steel can cause SCC. I am not aware that assuring flushing condition will avoid that. Why you think so?

Son reacts again: You can see many steam drums and pipelines are made by carbon steel as well.

Mark replies: Yes, but in HP urea equipment carbamate and carbonates can enter when there is a leak.

You can find more information about stress corrosion cracking in a publication by National Physical Laboratory, which you can download from UreaKnowHow.com’s E-Library.

The point I want to make is that in several cases cracks have been found on the liner side of the pressure bearing carbon steel wall and a connection with flushing with steam of condensate cannot be ruled out.

Mr Ashish Kumar Panda of OMIFCO in Oman contributes to the discussion: I have experience of leak detection in a urea reactor with ammonia vapour. The ammonia vapour after pressure reduction (as recommended by equipment manufacturer) is charged through one of the weep holes of the suspected leakage area. Other weep holes in the particular segment are kept plugged. Wet phenolphthalein paper is pasted inside the reactor. Leakage is detected by development of pink colour on the leakage point. This procedure is very effective in detecting very small leakages. Please ensure proper air purging inside the vessel to avoid accumulation of ammonia vapour. Breathing apparatus inside the vessel is a must.