Press Release: Greene Tweed achieves hydrogen compression breakthrough with record-speed composite impeller

Greene Tweed's advancement in hydrogen compression technology sets a record-breaking tip speed to 688 m/s in testing

Greene Tweed's advancement in hydrogen compression technology sets a record-breaking tip speed to 688 m/s in testing

MHI has successfully completed the Ghorasal Polash Urea Fertilizer Project in Bangladesh - the country’s largest fertilizer complex. Key features of the project include: the KM CDR Process™ that captures CO2 , cuts emissions and boosts urea output; an energyefficient granulation unit using a bulk flow cooler to reduce power demand; and reinforced digital safety management.

Advances in cooling technology are providing fertilizer facilities with new options when it comes to upgrading outdated equipment and improving environmental sustainability of their existing operations. Igor Makarenko of Solex Thermal Science explores cooling strategies to improve operational efficiencies while also reducing their energy consumption, greenhouse gas emissions and overall carbon footprint.

Globally, operational renewable ammonia projects have exceeded one gigawatt (GW) of installed electrolyser capacity for the first time. Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of well-advanced projects and the associated technology options for ammonia synthesis.

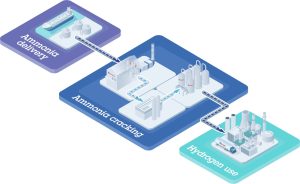

Air Liquide is developing a new ammonia cracking technology based on its proven steam methane reforming (including SMRX™ ) technology, which introduces a heat exchange concept to cut energy use, lower environmental impact, and potentially eliminate steam export. Leveraging extensive SMR design expertise, a robust R&D programme, and an industrialscale NH3 cracking pilot plant, it aims to rapidly mature all technology blocks and deliver safe, reliable, and customisable lowcarbon hydrogen solutions to meet growing demand.

Ammonia is poised to grow beyond fertilizers into energy transition roles, with lowcarbon pathways via blue ammonia and green ammonia, supported by existing logistics and market structures. To support this transition, Stamicarbon is expanding its NX STAMI™ ammonia technologies – with a mediumpressure design for large, CCUSintegrated plants and a highpressure design for small/ medium renewable projects – demonstrating efficiency, reliability, and cost advantages.

Sultech Global Innovation Corp., a Canadian agricultural technology company, has signed a memorandum of understanding (MoU) with ADNOC Sour Gas for its micronised elemental sulphur technology. Under the MoU, the companies will conduct a feasibility study and pilot production program to establish the UAE’s first commercial micronised sulphur manufacturing facility. The initiative will integrate Sultech’s patented micronisation process within ADNOC’s sulphur granulation at the Shah Gas Plant, the world’s largest ultra-sour gas operation.

NextChem and Siemens Energy have signed a memorandum of understanding to cooperate on the development and commercialisation of a high temperature methanol fuel cell, based on a newly designed modularised solution. With an initial focus on the high-end yachting segment, the target market for the cooperation is the maritime industry and beyond. According to the MoU, NextChem will focus on the design and supply of the methanol fuel cell module, while Siemens Energy will leverage its expertise in onboard system integration, complete electrification and energy management with the aim of delivering a complete solution to shipyards and owners.

Topsoe has been selected as the renewable diesel technology partner for CountryMark’s Mount Vernon, Indiana refinery. Located in southwestern Indiana, the refinery processes 35,000 bbl/d of crude oil. With the addition of Topsoe’s HydroFlex technology, CountryMark aims to produce up to 250,000 barrels of renewable diesel annually. The new unit is expected to enable an emission avoidance of approximately 84,500 t/a of CO2 e. CountryMark, a farmer-owned cooperative, will use local soybean oil as the primary feedstock to produce renewable diesel, helping create a locally sourced renewable fuel economy in Indiana.

thyssenkrupp nucera says that it has successfully completed the acquisition of key technology assets from Danish company Green Hydrogen Systems (GHS), as announced in June. The transaction was finalised following receipt of all necessary regulatory approvals and the consent of the court-appointed insolvency administrator. The asset deal includes intellectual property as well as a test facility with a full-size prototype in Skive, Denmark.