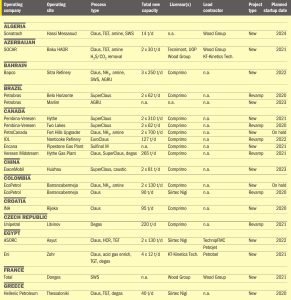

Sulphur recovery projects 2021

Sulphur’s annual survey of recent, current and future sulphur recovery unit construction projects maps the developing shape of brimstone production from fuel and gas processing plants worldwide.

Sulphur’s annual survey of recent, current and future sulphur recovery unit construction projects maps the developing shape of brimstone production from fuel and gas processing plants worldwide.

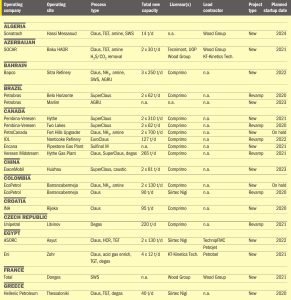

EcoMax™ tail gas catalysts offer a sustainable and cost effective choice for tail gas catalysts. They are made from spent hydroprocessing catalysts, which reduces the environmental and socioeconomic impacts of sourcing fresh cobalt and molybdenum and therefore supports operators’ sustainability goals. B. Visioli of Porocel (a part of Evonik) discusses the benefits of catalyst reuse from hydroprocessing for tail gas treating.

Storm Uri which blanketed the southern states of the US with snow, and led to widespread power outages in Texas, has had a major impact upon US Gulf Coast and Southern-Midwest refined products supply. Most Gulf Coast refineries were shut down or forced to operate at reduced rates. IHS Markit estimated that more than 5.2 million bbl/d of Gulf Coast capacity and 730,000 bbl/d in PADD 2 was impacted by the winter weather at its height, and close to 20% of lower 48 US natural gas production was shut-in in the first half of February. A drop in crude oil production of between 2.2 and 4 million bbl/d was estimated.

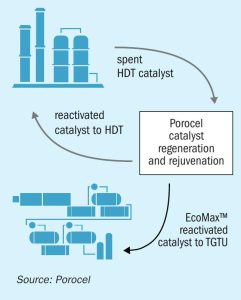

Failure investigations, equipment design and process upgrade projects for SRUs often overlook the impact of water quality. In this article E. Nasat o of Nasato Consulting and L. Huchler of MarTech Systems explore impacts of higher heat transfer rates, control of boiler and condenser water chemistry, conventional equipment design/configurations and monitoring program designs. SRU operators can improve the effectiveness of their failure investigations by implementing a broader, more holistic approach that assesses equipment design, process conditions, operating protocols and water quality issues.

New approaches and novel processing schemes employing oxygen enrichment in sulphur recovery units have been developed and commercialised. In this feature Siirtec Nigi, Linde, Blasch, Fluor and RATE report on their latest developments.

A. Bhargav and A. Krishnan of Helium Consulting Pvt. Ltd discuss how it is possible to reduce SOx emissions within the existing system setup of an oil refinery or gas plant through detailed analysis, expedited corrective actions and the use of automated algorithms in real-time, by using a digital IIoT solution to monitor, control and optimise.

In a few short years Abu Dhabi has grown to become the world’s largest sulphur producer and exporter, and new sour gas projects will lead to additional sulphur recovery capacity, provided they can overcome economic challenges.

A look at the major factors influencing the sulphur market around the world.

Sulphur’s annual survey of recent, current and future sulphur recovery unit construction projects maps the developing shape of brimstone production from fuel and gas processing plants worldwide.

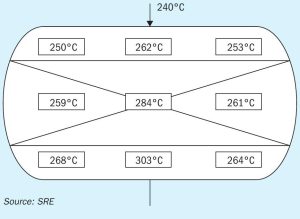

With the ongoing changes in gas field and refinery feedstock compositions, many sulphur recovery units around the world are facing turndown scenarios to such an extent that it is difficult to meet stringent environmental regulations. Equipment and instrumentation behave differently under turndown conditions, and not always in ways that are desirable. Start-ups and shutdowns can place demands on the equipment that are more severe than years of normal operation. In this article, Optimized Gas Treating, Sulfur Recovery Engineering and Comprimo share some of their learnings and experiences of these scenarios.