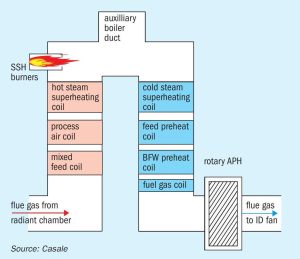

Casale granulation – revolutionising finishing technology

With the addition of Green Granulation technology (GGT), Casale is the only industry licensor able to provide customers with an entire nitrogen fertilizer complex. Ken Monstrey and Matteo Fumagalli of Casale outline the benefits of this technology and its revolutionary new elements.