The outlook for urea

Although the urea market has weathered the pandemic relatively well, a significant amount of new capacity is due to come on-stream in the next year or so, and could keep prices depressed unless more Chinese capacity closes.

Although the urea market has weathered the pandemic relatively well, a significant amount of new capacity is due to come on-stream in the next year or so, and could keep prices depressed unless more Chinese capacity closes.

While the covid pandemic has kept refinery run rates down in 2020, new refinery sulphur capacity will nevertheless form the bulk of new additions to sulphur production over the next few years. But delays to projects on both the supply and demand sides could tip a fairly balanced market in either direction.

Metal processing in Northeast Asia is the major source of sulphuric acid exports from the region, and the ramp up of Chinese copper smelter capacity is leading to increased acid availability.

Calgary-based Pieridae Energy Ltd says that it has hired a new Chief Operating Officer as from April 5th. Darcy Reding is a professional engineer with 30 years of experience in small and medium-sized private and public upstream oil and gas companies, 20 years of that in leadership roles. Reding spent the last decade at NAL Resources as VP of Operations and VP Operations & Geoscience. Prior to NAL, Reding held technical and leadership roles with Norcen Energy, Northrock Resources, Samson Exploration and Enterra Energy Trust.

There is an old adage that if you put two economists in a room, you will get three different opinions. As the world enters its second year of dealing with the coronavirus pandemic, that certainly still seems to be the case among those grappling with predicting an increasingly uncertain world.

With declining ore grade feed to a metallurgical smelting process comes an increase in impurity load in the gas cleaning/acid process chain. K. Hasselwander, L. Skilling and C. Bartlett of Metso Outotec discuss a range of process solutions and how to maintain high productivity while keeping costs in check.

We report on the latest potash mining and processing technology from Andritz, Ebner, Köppern, K+S and Veolia. Recent case studies for potash projects globally are also provided.

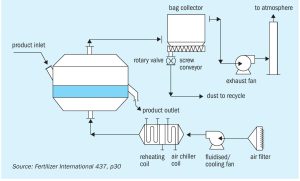

Plant operators require effective and efficient equipment for cooling the solid materials generated during fertilizer production. The main options include fluid bed coolers, rotary coolers and bulk flow coolers.

We profile a selection of the leading players in India’s large and dynamic domestic fertilizer industry.

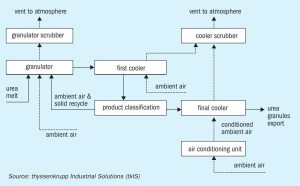

Globally, thyssenkrupp Industrial solution (tkIS) has engineered and built nine urea granulation plants during the last 10 years. Based on this experience, Benedict Jass, Marc Wieschalla and Ivo Mueller of tkIS describe two different cooling concepts for urea granules – fluid bed cooling and bulk flow cooling – and their contrasting advantages and disadvantages.