Process gas boilers with bypass for steam methane reformers

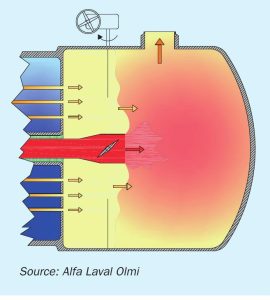

Process gas boilers with an internal bypass system are an important type of shell-and-tube heat exchanger installed in steam methane reforming units. For decades, two traditional designs have dominated the market: the “hot” and “cold” bypass process gas boiler. Today, a third option based on a new design concept is available: the “bayonet” bypass process gas boiler, with process and mechanical features that can provide superior performance, lower opex and improved reliability. G. Manenti of Alfa Laval Olmi SpA discusses the design and operating principles of the different designs.