Nuclear powered ammonia

With green ammonia from renewable energy facing cost hurdles to adoption, thoughts have turned to using nuclear energy as a carbon free alternative.

With green ammonia from renewable energy facing cost hurdles to adoption, thoughts have turned to using nuclear energy as a carbon free alternative.

As Comprimo celebrates its 100th anniversary, we explore the group’s history from its earliest days in the Netherlands in the 1920s to its current status as a global leader in gas treatment and sulphur recovery technology.

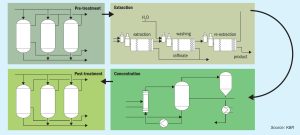

KBR designs and builds customised phosphoric acid purification plants tailored to the individual demands of clients. Christopher Heikkilä, KBR’s Business Development Manager, outlines the process design requirements and the challenges associated with impurities removal.

How does an engineering company complete the basic and detailed engineering for a phosphoric acid plant – and provide the full design for the off-site sections and utilities? Jan Tytgat, De Smet Agro’s Process Engineering Manager, explains an approach based on partnership with the technology licensor and client that combines engineering expertise with experience.

Morocco’s OCP is continuing to expand its phosphate fertilizer production capacity. This includes the construction of new sulphur-burning acid capacity to support phosphate production and provide carbon-free power.

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

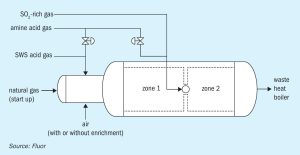

Fluor investigates how SO2 impacts the Claus furnace temperature in an SRU and the ways to mitigate it. This article studies the extent of quenching experienced in the Claus furnace with varying amounts of SO2 in the Claus feed. A case study is presented based on real operating data of a refinery Claus plant with a feed gas cocktail that includes substantial SO2 recovered from a regenerative flue gas desulphurisation unit.

Evaporation and crystallisation are widely used throughout the fertilizer industry. These powerful production processes are helping fertilizer manufacturers diversify their product portfolios, improve profitability and meet sustainability goals.

Bedeschi has been awarded a contract by Tecnicas Reunidas and Wison Engineering for the engineering and supply of new sulphur-handling equipment. Tecnicas Reunidas and Wison Engineering are working in a 70-30 joint venture partnership on the North Field Expansion Project (NFXP) Sulphur Project, which forms part of the overall Qatar North Field Expansion Project. Last year were awarded a $600 million contract to process and export sulphur from the projected expansion of the liquefied natural gas (LNG) facilities in Ras Laffan Industrial City. The new sulphur plant will have the capacity to process an average of 5,000 t/d of molten sulphur.

Sulphurnet discusses the importance of a whole life cycle cost analysis at the conceptual design phase when making investment decisions about new sulphur processing facilities.