Phosphates project listing 2021

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

Fertilizer International presents a global round-up of phosphate rock, phosphoric acid and finished phosphates projects.

Johnson Matthey and KBR have announced that they have signed a global strategic alliance agreement to license a new ammonia-methanol co-production process that combines the companies’ ammonia and methanol process technologies. The companies say that the co-production process makes the most of synergies between the two technologies, maximising savings while offering the highest levels of safety, flexibility and reliability.

Fertilizer International presents a global round-up of current potash projects.

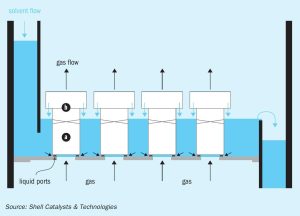

G. Bowerbank and W. Blas of Shell Catalysts & Technologies discuss low cost strategies to maximise value at existing gas processing facilities. Changing solvents, introducing advanced column internals or a combination of both are relatively simple and cost-effective options for boosting production or revenue with minimal investment.

Haldor Topsoe and Comprimo® have announced a global strategic alliance to jointly license the TopClaus sulphur removal and recovery technology. TopClaus combines Topsoe’s energy efficient wet sulphuric acid (WSA) process with the industry-standard Claus process, enabling plant operators to handle acid gases and achieve sulphur removal efficiencies of above 99.9%. The Claus part of the unit recovers elemental sulphur from acid gases, and the tail gases from the Claus unit are then treated in the WSA unit, where the remaining sulphur compounds are converted into sulphuric acid.

Air Products and Haldor Topsoe have signed a global alliance agreement. Under the terms of the agreement the two companies will use their combined market network for developing potential projects and the combination of their expertise on large-scale ammonia, methanol and/or dimethyl ether (DME) plants to be developed and built globally. It gives Air Products access to Topsoe’s technology licenses and the supply of engineering design, equipment, high-performance catalysts and technical services for ammonia, methanol and DME plants that are built, owned and operated by Air Products. It also allows for the integration of Topsoe’s technology into many Air Products’ technologies including gasification of various feedstocks, and synthesis gas processes.

Tecnimont SpA has signed an EPC contract worth approximately e200 million with Gemlik Gübre Sanayii Anonim Sirketi for the construction of a new urea and urea ammonium nitrate (UAN) solutions plant at Gemlik, 125 km south of Istanbul. The plant will have a capacity of 1,640 t/d of granular urea and 500 t/d of UAN, and will be based on Stamicarbon urea technology, a fully owned subsidiary of the Maire Tecnimont group. The scope of work includes engineering, supply of all equipment and materials and construction and erection works. Project completion is planned within about three years of the contract beginning.

The Indonesian government’s decision to enforce the processing of more copper and nickel ores domestically rather than export them to China has led to the rapid development of domestic smelter capacity as well as nickel acid leaching projects.

Although North America is no longer the world’s largest sulphur exporter, it remains a major producer and consumer, and there are still significant exports and imports of sulphur into and out of the region.

China’s copper industry is facing difficulties caused by the coronavirus outbreak in the country. Prolonged factory closures, particularly in Hubei province, at the centre of the outbreak, as well as neighbouring Guangdong and Zhejiang, also badly affected, have caused a slump in demand for copper domestically as copper fabricators remain on extended closure. However, smelters have resisted cutting production. Daye Nonferrous, based in Huangshi at the centre of coronavirus outbreak, continues to operate at 80% of its 600,000 t/a capacity for 1Q 2020, according to the company, in spite of quarantine and transport restrictions which have reduced truck shipments to the smelter – Daye is reportedly still able to receive copper concentrate shipments via the Yangtze River to Huangshi port.