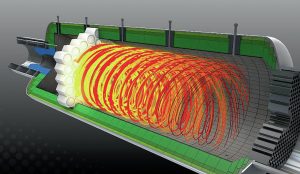

A novel combustion solution

A new burner design for the combustion of natural gas with either combustion air or pure oxygen as the oxidiser has been developed by CS Combustion Solutions. The new Oxijet®-Burner has been designed to perform both start-up and main operation functions with one burner.