Towards a sustainable nitrogen fertilizer industry:

Georgy Eliseev , Principal Analyst at Fertecon for IHS Markit, looks at the medium to long term outlook for both ‘green’ and ‘blue’ ammonia production.

Georgy Eliseev , Principal Analyst at Fertecon for IHS Markit, looks at the medium to long term outlook for both ‘green’ and ‘blue’ ammonia production.

Demand for nickel sulphate is expected to rise rapidly this decade to feed increased battery production for electric vehicles. At the same time, diminishing sources of high grade nickel ores are leading to a renewed focus on high pressure acid leaching (HPAL) of laterite ores, with a significant impact on sulphur and sulphuric acid demand.

Copenhagen Infrastructure Partners (CIP) has unveiled plans to build Europe’s largest power-to-ammonia facility at the Danish port of Esbjerg, based on electricity from offshore wind turbines. The company said the plant will consist of 1GW of electrolysis capacity, capable of supplying sufficient hydrogen to produce 300,000 t/a of ammonia, and that the ammonia will be used as both as agricultural fertiliser and as fuel for the shipping industry. Excess heat generated in the process would be used to provide heating for around one third of local households in communities around the plant, to be sited on the west coast of Denmark. The company has signed a memorandum of understanding for the project with companies from both the agriculture and shipping sectors, including Danish Crown, Arla, DLG, Maersk and DFDS Seaways. CIP anticipates that it would cost approximately $1.2 billion to build the facility. They are currently seeking investors for the project and expect that the investment decision would be reached by 2023. The plant could enter commercial operations in 2026.

Bodo Albrecht, BASF writes: Among the many sad news of 2020 is the passing of Alan Heywood, a leading authority in the advancement of nitric acid catalysts and recovery systems. At the time I first met Alan in 1997, he already had 6 patents to his name ranging from improved aircraft gas turbine igniters and “ZGS” grain stabilized precious metal composite materials to PGPs “cartridge” catalyst, arguably the first true catalyst system ever produced.

Newly-developed froth flotation equipment and reagents are improving selectivity and the grade and recovery of phosphate concentrates.

Clariant, says that Conrad Keijzer become its new chief executive officer as of January 1st, 2021. Interim executive chairman Hariolf Kottmann has thus returned to his position as chairman of the board. Keijzer is a Dutch citizen with a long track record in the chemical industry, including 24 years with leading global paints and coatings manufacturer AkzoNobel, where he was CEO of the Performance Coatings Division and a member of the Executive Committee. Most recently, Conrad Keijzer was CEO of Imerys, a French supplier of mineral-based specialty solutions.

Alexander Prygunkov became Uralchem’s new CEO on the 4th December. Mr Prygunkov, who was formerly PIK Group’s chief operating officer, will focus on the digital transformation of the company. He is also expected to strengthen Uralchem’s position in the chemicals and agricultural industries, and introduce a more modern approach to business management.

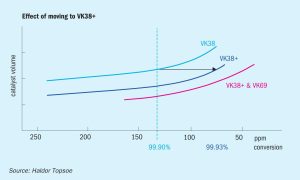

Selecting the right catalysts for the SO2 converter in a sulphuric acid plant has always been about balancing expenses, gains, and compliance. With increasing demands for sustainability and in challenging economic times, operators need to adjust their plants to get even more from less. This has led to market demand for new catalytic solutions that offer better productivity and a lower climate footprint, all at the lowest cost possible. Catalyst design and formulations continue to evolve with Haldor Topsoe, DuPont Clean Technologies and BASF all adding new types of sulphuric acid catalysts to their portfolios.

Norilsk Nickel has finally closed down its nickel smelting operation at Nikel in Russia’s Murmansk region; the company’s oldest still operating production facility. The shutdown is part of the company’s environmental programme, which aims to significantly reduce its environmental impact at all production sites. The Nikel closure will eliminate SO2 emissions in the cross-border area with Norway, which had become a major bone of contention with the Norwegian government. Norilsk aims to reduce SO2 emissions at Kola by 50% by the end of 2020 and 85% by the end of 2021, and is modernising its production in Monchegorsk, including the construction of new state-of-the-art facilities.

The coronavirus outbreak necessitated a ‘virtual’ CRU Sulphur + Sulphuric Acid conference last year, held in November 2020.