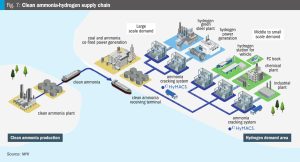

MHI successfully produces hydrogen at ammonia cracking pilot plant

Mitsubishi Heavy Industries says that it has succeeded in producing 99% pure hydrogen by cracking ammonia using steam as the heating source. The production of hydrogen at pilot scale using the steam heating was conducted at the company’s pilot plant in the Nagasaki District Research & Innovation Centre, marking a world first. By contrast to technologies that use heat from burner combustion, MHI’s steam heating system operates at lower reaction temperatures, reducing operating costs. In addition, because a combustion furnace is not required, the system offers excellent features such as the potential for miniaturisation.