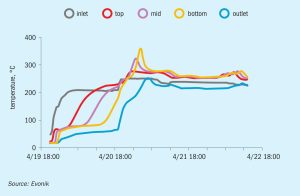

When digitalisation meets reality

In 2019 Topsoe launched its ClearView™ technology for WSA and SNOx sulphuric acid plants. This article focuses on the results and learnings from the first implementation of ClearView™ at a new WSA plant at Anglo American Platinum’s Polokwane smelter in South Africa.