Sulphur in agriculture

Sulphur’s key role as a plant nutrient means that its use as a fertilizer continues to be a major area of demand.

Sulphur’s key role as a plant nutrient means that its use as a fertilizer continues to be a major area of demand.

Tight supply limits availability as China maintains export restrictions.

Rapidly increasing lithium production is projected to require several million t/a of sulphuric acid in the next few years, with China, the USA and Australia the main consumers.

Building on the success of its previous conferences, SulGas Mumbai 2025 brought together 154 sulphur and gas treating stakeholders, representing 68 companies for its 7th technical forum in the Indian subcontinent. We report on some of the key topics on the agenda.

The first installed combination of a regenerative SO2 scrubbing system with a sulphuric acid plant using Worley Chemetics’ CORE™ reactor technology started up in November 2022. The combination of these technologies allows production of high-grade sulphuric acid from gases with low and/or fluctuating SO2 concentrations. C. Trujillo Sanchez and R. Dijkstra of Worley Chemetics report on the design concepts of this integrated process, highlight where it is most effective and report on the start-up and first years of operation of the plant.

Apart from having a good plant design, good maintenance practices and good operational discipline are key to optimise the performance of an acid plant and to protect it from corrosion and achieve a long life. B. Mumba, T. Mwanza and P. Ng’ambi of Kansanshi Mining PLC explore the Kansanshi sulphuric acid plant operations and the key parameters monitored and practices adopted that have helped to extend the catalyst campaigns from two years to four years.

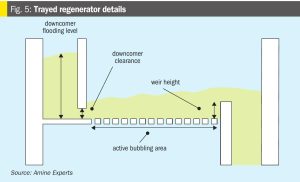

Preventing regenerator amine carryover to the sulphur recovery unit can have catastrophic consequences and must be avoided at all costs. B. Spooner and M. Sheilan of SGS Amine Experts detail how by correctly interpreting operating data, having proper instrumentation and good chemical analysis, amine carryover can be prevented.

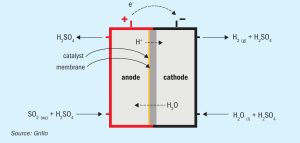

New concepts focused on the transfer and combination of existing sulphur and sulphuric acid technologies to support decarbonisation of the sulphuric acid industry are being investigated. In this article three research projects are discussed: sulphur dioxide depolarised electrolysis for green regeneration of spent acid, use of renewable heat and catalyst to the splitting process from sulphuric acid to SO2 for reduction of fossil fuel consumption, and sulphur as an energy vector.

Nickel sulphate is an intermediate step in the production of materials for batteries, and is seeing rapid demand growth as the auto industry moves towards electric power trains.

The 2030 greenhouse gas emission reduction goals in the European Union are driving oil and gas producers to reduce CO2 emissions wherever possible. This extends to even the incinerator attached to a sulphur recovery unit (SRU). In this article Sulphur Experts review the role of the incinerator, how the three most common European TGUs each affect the demand on the incinerator itself, and the potential reduction in CO2 emissions for a generic facility of each type.