Nitrogen + Syngas 2023

CRU Events will host the 2023 Nitrogen + Syngas conference and exhibition at the Hyatt Regency Barcelona Tower in Barcelona, 6-8 March.

CRU Events will host the 2023 Nitrogen + Syngas conference and exhibition at the Hyatt Regency Barcelona Tower in Barcelona, 6-8 March.

Cansu Doganay of Lux Research takes a look at the current technology landscape for methane pyrolysis for producing low-carbon hydrogen from natural gas.

A review of the current slate of plans for green and blue ammonia production.

Covid, demographics and a shift from an industrial to a consumer-led economy have stalled China’s previously breakneck growth, with a potential impact upon all commodity markets, including fertilizer. At the same time, Chinese export restrictions have overheated the urea market.

With Europe facing a long-term shortage of natural gas, and Russia looking east for new customers, how will changing global gas markets affect production of key syngas-based chemicals?

Ammonia prices registered another week of losses at the start of January, with supply options continuing to outweigh demand in most regions. Prices have been falling steadily for the past twelve weeks, as the market rebalances after production curtailments across Europe for much of 2022. Steady falls in gas pricing over the past few weeks have put production costs firmly below today’s import price, with European production now scheduled to ramp up at many plants this month.

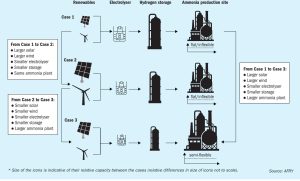

Due to the inherent nature of the renewable power, sizing eSyngas plants powered with renewable energy brings complexity normally not faced by natural gas-based facilities. In this article, Dr Raimon Marin and Dr Solomos Georgiou of AFRY discuss the application of AFRY’s state-of-the-art modelling tool to optimise the size and production of a green hydrogen system and a green ammonia plant based on given renewable power profiles and their associated variability (e.g., hourly, daily, seasonally, and annually).

The market is anticipated to correct lower throughout the rest of the first quarter. Once a clearer picture over seasonal fertilizer demand in Europe emerges, this could stabilise downward momentum.

Air Liquide presents the results of an internal study to identify preferred natural gas-based plant configurations at a methanol capacity of 250 t/d. Delivering small capacity plants requires a focus on the total cost of ownership (TCO) for the economics to be successful, in addition to the CO 2 footprint of the operation. As found by this study, SMR concepts are naturally power balanced for standalone greenfield operations and show no particular advantage for power import in a brownfield setting. POX and ATR cases are greatly improved and even advantaged in a brownfield setting compared to SMR when shifting from power balance to power import cases.

Advanced Methanol Amsterdam (AMA) is a production facility, that will be realised in the Port of Amsterdam's Biopark, which is destined to produce advanced methanol that meets the European renewable energy directive (RED) requirements. Once completed, AMA will be the flagship production site for GIDynamics and GIDARA Energy and for its High Temperature Winkler (HTW ® ) gasification technology. AMA will also be the first of its kind green methanol unit designed by Casale.