Urea technology showcases

Casale, Saipem, Stamicarbon & Toyo Engineering Corporation showcase a selection of innovative technologies that have recently been brought to the market.

Casale, Saipem, Stamicarbon & Toyo Engineering Corporation showcase a selection of innovative technologies that have recently been brought to the market.

The reliability of primary reformers is a key issue for syngas plants. Quest Integrity describes the damage mechanisms and material limitations that impact the reliability of reformer outlet systems and the improvements that may be implemented.

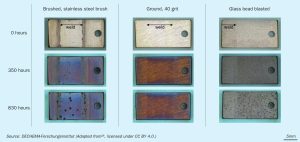

Industrial plants using synthesis gas at elevated temperatures risk metal dusting attack on the equipment, which are typically made of steels or Ni-based alloys. Parameters which impact the metal dusting risk are discussed and factors affecting the material selection and processing are described. One important focus is surface preparation, showing that grinding (40 grit) improves the metal dusting resistance compared to glass bead blasting and brushing. The surface treatment outweighs the impact of welds or the manufacturing route.

A review of the current slate of plans for green and blue ammonia production.

Although global ammonia supply is set to increase this year, there is a shortage of new merchant capacity after 2024 which may lead to rising prices in the medium term.

Large-scale ammonia cracking technology and catalysts will enable the full potential of ammonia to be realised as industries transition towards low carbon energy. In this feature we report on the current status of ammonia cracking processes and catalysts.

Low emissions hydrogen is expected to play an increasing role in the syngasbased chemicals industry, but cost and technical challenges remain.

Although it has been a major exporter of urea, increasing Chinese government restrictions have restricted the seasonal window for exports.

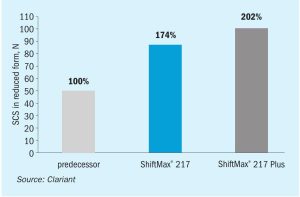

Anton Kariagin and Stefan Gebert of Clariant discuss the benefits and commercial performance of the new low temperature shift (LTS) catalyst – ShiftMax 217 Plus. A case study demonstrates the benefits of this catalyst, providing ultra-low methanol formation resulting in increased ammonia production and/or energy savings.

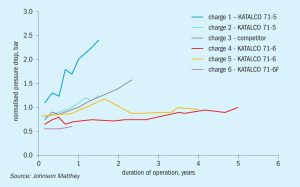

Johnson Matthey's latest KATALCO™ 71-7F high temperature shift catalyst with its robust shape provides lower lifetime pressure drop.