Sustainable fertilizer production

Pejman Djavdan , CEO of Stamicarbon looks at the ways in which the fertilizer industry must grapple with issues such as decarbonisation, sustainability and more efficient use of nutrients.

Pejman Djavdan , CEO of Stamicarbon looks at the ways in which the fertilizer industry must grapple with issues such as decarbonisation, sustainability and more efficient use of nutrients.

SABIC’s general assembly has approved the appointment of Abdulrahman Al-Fageeh as SABIC CEO, and an executive member of the board of directors until April 9, 2025 – the Board’s tenure end date. In its previous meeting, the Board of Directors, had agreed to appoint Dr. Mohammed Yahya Al-Qahtani as vice chairman. At the meeting, Khalid Al-Dabbagh, SABIC Chairman, noted that the past year had been difficult one, though “SABIC managed to face the challenges by intensifying its development programs to achieve record numbers in terms of production, sales, and revenues that exceeded the achievements of the previous year. However, its net profits have not met its aspirations and have shrunk compared to last year due to the worsening global conditions.” He also said that SABIC is pursuing plans to manage working capital through the Cash Cost Transformation program, and is sparing no effort to achieve sustainable growth, adopt long-term strategic goals for sustainability, and reduce emissions related to the life cycle of its products across the value chain.

Gasification, particularly of waste and biomass, is seeing interest as sustainable sources of syngas. But there are both technical and commercial challenges to wider adoption.

Johnson Matthey (JM) has signed an LCH™ technology licence with Equinor and Linde Engineering for H2H Saltend, one of the UK’s largest low carbon hydrogen projects. JM was selected alongside EPC partner Linde Engineering for the major FEED contract by Equinor. The licence counts towards JM’s milestone of winning more than ten additional large-scale projects by 2023/24.

Nitrogen+Syngas’s annual listing of new ammonia, urea, nitric acid and ammonium nitrate plants.

Further downward corrections are possible but the rate of demand is stabilising, suggesting the market floor is in sight, though some have suggested that May could bring another sharp reduction in the Tampa contract price towards the mid$300s c.fr. Demand remains sluggish in both eastern and western hemispheres.

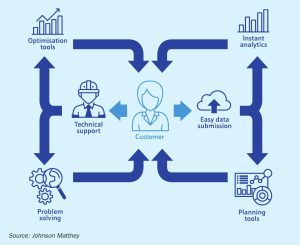

Combining a deep scientific knowledge, engineering and field experience with state-of-the art technology, Johnson Matthey is proud to introduce its next generation of digital simulation tools via its JM-LEVO™ digital portals to further support customers in achieving their operational and sustainability targets.

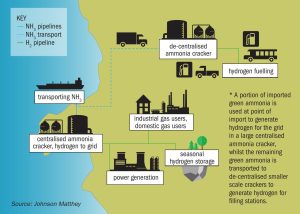

Advances in clean hydrogen and ammonia production is fuelling worldwide interest in a new market for hydrogen and ammonia to provide a reliable low-carbon energy future. Ammonia cracking, the dissociation of ammonia back into hydrogen, delivers a pathway to large-scale sustainable hydrogen production. In this article KBR, Johnson Matthey, thyssenkrupp Uhde, Duiker, Proton Ventures and Casale report on their technologies and approaches to ammonia cracking in a low carbon economy.

With the market for green ammonia set to grow significantly in the coming years, modularisation of ammonia plants can bring many benefits to new projects, including optimised cost, speed of delivery and reducing overall risks. thyssenkrupp Uhde is committed to further develop standardised, modular solutions for its clients. Tobias Birwe and Dustin Mayor explain the company’s modularisation concept.

In 1967 Stamicarbon revolutionised the urea process by the invention of the high-pressure CO2 stripper by Petrus J. C. Kaasenbrood. The high-pressure CO2 stripper led to following benefits: