2025 AIChE Ammonia Safety Symposium

Venkat Pattabathula reports on the American Institute of Chemical Engineers’ (AIChE) Safety in Ammonia Plants and Related Facilities Symposium, held from September 7–11th 2025, in Atlanta, Georgia, USA.

Venkat Pattabathula reports on the American Institute of Chemical Engineers’ (AIChE) Safety in Ammonia Plants and Related Facilities Symposium, held from September 7–11th 2025, in Atlanta, Georgia, USA.

MHI has successfully completed the Ghorasal Polash Urea Fertilizer Project in Bangladesh - the country’s largest fertilizer complex. Key features of the project include: the KM CDR Process™ that captures CO2 , cuts emissions and boosts urea output; an energyefficient granulation unit using a bulk flow cooler to reduce power demand; and reinforced digital safety management.

The following case study describes a serious incident and the consequences of erroneously mixing nitric acid with hydrochloric acid. In Part 1 we reported on the incident and the causes that led up to the event. In part 2 the impact, recommendations and lessons learned will be discussed.

Advances in cooling technology are providing fertilizer facilities with new options when it comes to upgrading outdated equipment and improving environmental sustainability of their existing operations. Igor Makarenko of Solex Thermal Science explores cooling strategies to improve operational efficiencies while also reducing their energy consumption, greenhouse gas emissions and overall carbon footprint.

Globally, operational renewable ammonia projects have exceeded one gigawatt (GW) of installed electrolyser capacity for the first time. Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of well-advanced projects and the associated technology options for ammonia synthesis.

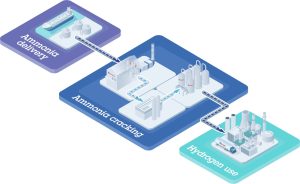

Air Liquide is developing a new ammonia cracking technology based on its proven steam methane reforming (including SMRX™ ) technology, which introduces a heat exchange concept to cut energy use, lower environmental impact, and potentially eliminate steam export. Leveraging extensive SMR design expertise, a robust R&D programme, and an industrialscale NH3 cracking pilot plant, it aims to rapidly mature all technology blocks and deliver safe, reliable, and customisable lowcarbon hydrogen solutions to meet growing demand.

Ammonia is poised to grow beyond fertilizers into energy transition roles, with lowcarbon pathways via blue ammonia and green ammonia, supported by existing logistics and market structures. To support this transition, Stamicarbon is expanding its NX STAMI™ ammonia technologies – with a mediumpressure design for large, CCUSintegrated plants and a highpressure design for small/ medium renewable projects – demonstrating efficiency, reliability, and cost advantages.

thyssenkrupp Uhde says that it has successfully commissioned a hydrogen recovery unit (HRU) at the Fertil ammonia-urea plant in Ruwais, owned by Fertiglobe, a global exporter of urea and ammonia. The scope of work included engineering, procurement and site supervision during installation and start-up of the units.

As I write this editorial, the 30th meeting of the Conference of the Parties (COP) to the UN Framework Convention on Climate Change – aka COP-30 – is taking place in Brazil. It is fair to say that the attempt to try to restrict a large greenhouse gas-driven temperature rise across the planet has become one of the defining issues of our age, and particularly for an energy-intensive industry such as our own, responsible as it is for up to 2% of global carbon and carbon equivalent emissions. The move towards lower carbon intensity production of hydrogen, ammonia and methanol, via carbon dioxide capture and sequestration, gasification of biomass or waste, or electrolysis of water using renewable power, has come to dominate our news coverage, and in this issue we also carry articles on the state of play of both ‘blue’ and ‘green’ ammonia production, as well as technology for ‘cracking’ ammonia back to hydrogen and nitrogen for its potential use as a hydrogen carrier.

As part of the Japanese government’s Green Transformation scheme, two hydrogen producers have been selected to receive subsidies for low-carbon production projects. Out of the overall $1 trillion GX scheme, $51 billion is earmarked for hydrogen and ammonia investments, with the bulk going towards a long-term programme that subsidises the increased production costs. The first two recipients are a Toyota Tshuho-led consortium (electrolytic hydrogen for steel), and Resonac (hydrogen from used plastics for ammonia). In the programme, production projects are required to have the support of a major hydrogen consumer – in Resonac’s case, this is Japanese chemicals giant Nippon Shokubai, who will offtake the ammonia produced from lower-carbon hydrogen.