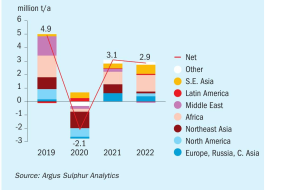

Price Trends

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Meena Chauhan , Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

Sulphur processing from sour gas fields dominates regional production, but the geographical remoteness of the area from end use markets and restrictions on sulphur storage means that producers often opt to reinject acid gas into oil and gas wells.

Are we on the verge of a fertilizer production, trade and supply crisis? Some usually sober and authoritative voices seem to think so.

Market Insight courtesy of Argus Media

The feed phosphates industry is caught between conflicting trends currently, according to Alberto Persona of the Fertecon fertilizer team at IHS Markit. While the long-term demand-side fundamentals look broadly stable, there is still likely to be a fight for market share due to competition from substitute products and the emergence of new projects.

More than 230 delegates from 45 countries participated in CRU’s Sustainable Fertilizer Production Technology Forum, 20-23 September 2021. To highlight this successful virtual event, we report on keynote and selected technical presentations.

Fertilizer International presents a global round-up of current potash projects.

ACI will convene the 5th European Mineral Fertilizer Summit in London on 1-2 December 2021. Fertilizer International is proud to be a partner for this year’s event.

Market Insight courtesy of Argus Media

A move towards smaller scale feedstocks such as renewable energy and waste and biomass gasification is leading to increased focus on improving the efficiency of small-scale, modular plants.