Redefining economical small-scale methanol production

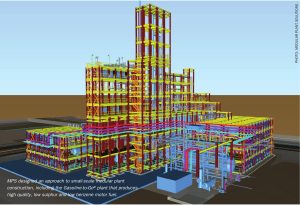

Modular Plant Solutions (MPS) introduces the MeOH-To-Go® plant, a new approach to methanol production through small-scale, modularised plant design.

Modular Plant Solutions (MPS) introduces the MeOH-To-Go® plant, a new approach to methanol production through small-scale, modularised plant design.

Cover story! CASALE’s Giovanna Roviello and Francesco Baratto provide an update on the Villeta 'green' fertilizer project in Paraguay.

Brazil is well-positioned to lead the global transition to low-carbon ‘green’ fertilizers, suggests Petter Ostbo, CEO and founder, Atlas Agro.

CF Industries has made its first shipment of certified low-carbon ammonia to Europe.

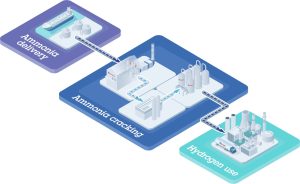

Air Liquide is developing a new ammonia cracking technology based on its proven steam methane reforming (including SMRX™ ) technology, which introduces a heat exchange concept to cut energy use, lower environmental impact, and potentially eliminate steam export. Leveraging extensive SMR design expertise, a robust R&D programme, and an industrialscale NH3 cracking pilot plant, it aims to rapidly mature all technology blocks and deliver safe, reliable, and customisable lowcarbon hydrogen solutions to meet growing demand.

Could demand mandates help the build the market for green fertilizers – by placing mandatory purchasing requirements on large-scale end users?

Delegates gathered in Morocco in September for AFA's Technical Conference. We present selected highlights from this year’s event.

Kevin Rouwenhorst of the Ammonia Energy Association (AEA) provides an overview of green ammonia projects and the associated technology options.

Swiss technology company ABB has signed a term sheet agreement with SwitcH2 to engineer and supply automation and electrification solutions for SwitcH2’s floating production, storage and offloading (FPSO) unit dedicated to producing green ammonia from green hydrogen, to support future demand for low-carbon marine fuels.

IFA has announced the finalists of its first-ever competition to find the next generation of innovative companies.