Sulphur forming project listing 2020

Sulphur ’s annual listing of new or recently completed sulphur forming projects worldwide covers both new sour gas and refinery sulphur forming projects as well as upgrades at existing units.

Sulphur ’s annual listing of new or recently completed sulphur forming projects worldwide covers both new sour gas and refinery sulphur forming projects as well as upgrades at existing units.

“T here are,” Mark Twain once remarked, “three kinds of lies: lies, damned lies, and statistics.” It’s certainly difficult to know what to make of economic statistics and indicators at the moment, in the world turned upside down that the Covid-19 pandemic has delivered. Here in the UK, we are told that April and May saw the national economy contract by 25%, the largest fall in 300 years of the Bank of England’s economic record keeping, and the situation is very similar across much of the developed world. But how real is that figure? After all, we were all sent home in March, to ‘lock down’ and prevent the spread of the virus, and we are only now starting to move back towards some semblance of normality. Some of us, fortunately or not, have still been able to work from home, but for much of the economy, especially for much of the service sector; tourism, travel, restaurants and hotels, theatres and cinemas – there has been zero activity. Remove half of the largest sector of the economy for three months and surely a 25% fall in output is exactly what you’d expect? But is that real, or just a number? Has that activity gone for good, or, now that we are emerging, blinking into the sunlight again, can we switch the economy back on again as easily as we switched it off?

On June 30th, following clearance from the European Commission, Outotec completed the year-long merger of Metso’s Minerals business with Outotec via a partial demerger of Metso. The newly formed company, Metso Outotec, will focus on leadership in sustainable minerals and metals processing and recycling technologies. Headquartered in Finland, Metso Outotec employs over 15,000 professionals in more than 50 countries and its combined sales for 2019 were e4.2 billion.

IPCO provides an update on its latest activities, with flexible processes enabling IPCO’s project for the first drum granulation plant in Europe to remain on track despite unprecedented Covid-19 restrictions.

Fugitive dust emissions during the handling and storage of formed sulphur can result in negative environmental impacts and under specific conditions result in an explosion hazard. Enersul has developed a dust suppression system specifically targeted at controlling sulphur dust particles. The Enersul SafeFoam Transfer System (STS) reduces sulphur fines at critical transfer points throughout any sulphur handling system, resulting in a significantly safer and more environmentally friendly sulphur handling system.

We profile the US ‘big three’ North American phosphate producers, Mosaic, Nutrien and Simplot, and disruptive market entrant Itafos.

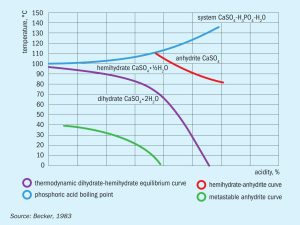

The DA-HF phosphoric acid process has been successfully implemented at Grupa Azoty’s Police fertilizer production plant in Poland, as part of a revamp of the site’s existing DH plant. Sébastien Havelange and Alexandre Wavreille of Prayon Technologies outline the performance improvements achieved by this first-of-its-kind plant.

Three large-scale phosphoric acid plants constructed as part of the world-class Umm Wu’al project in Saudi Arabia are now fully operational. James Byrd of Worley (formerly Jacobs ECR) describes the execution of the project from basic engineering through to plant performance tests.

Nutrien is the world’s largest crop nutrient company with a market capitalisation of almost $20 billion (Figure 1). This fertilizer industry giant produces and distributes over 25 million tonnes of potash, nitrogen and phosphate products for agricultural, industrial and feed customers globally. The company’s agriculture retail business also serves over 500,000 growers worldwide through a network of international outlets.

Nutrien has temporarily shut down one of the four ammonia plants at its Trinidad production site.