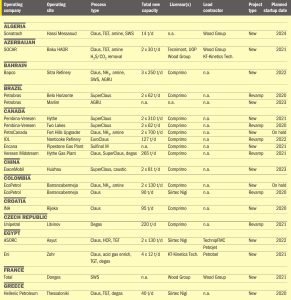

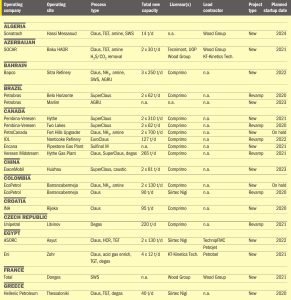

Sulphur recovery projects 2021

Sulphur’s annual survey of recent, current and future sulphur recovery unit construction projects maps the developing shape of brimstone production from fuel and gas processing plants worldwide.

Sulphur’s annual survey of recent, current and future sulphur recovery unit construction projects maps the developing shape of brimstone production from fuel and gas processing plants worldwide.

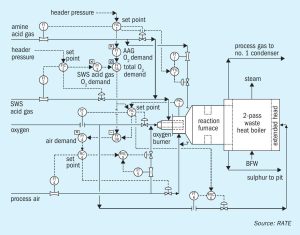

With the sulphur content of crude oil and natural gas on the increase and with the ever-tightening sulphur content in fuels, refiners and gas processors will require additional sulphur recovery capacity. At the same time, environmental regulatory agencies of many countries continue to promulgate more stringent standards for sulphur emissions from oil, gas and chemical processing facilities. Rameshni & Associates Technology and Engineering discusses options for compliance with new regulations on emissions regarding IMO 2020 compliance and report on the results and evaluation of three case studies. Worley Comprimo reports on the revamp of a sulphur complex built in the late 1980s at a refinery in East Asia with the aim to increase the capacity, improve the availability and reliability and make the unit environmental compliant.

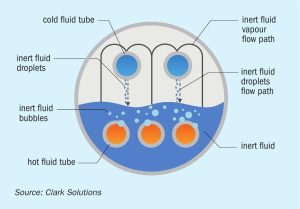

N. Clark, B. Avancini and V. Sturm of Clark Solutions discuss a novel technology, SAFEHX® , providing a new approach to the cooling of strong sulphuric acid. Prototype results are shown and indicate a safe and stable cost-effective technology. SAFEHX® can be extended to every heat exchanger system where corrosion, mixture risks, fouling, process liquid loss (or contamination) and temperature control are key concerns.

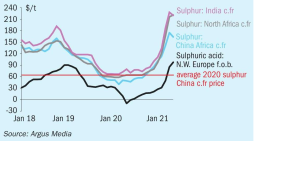

While the covid pandemic has kept refinery run rates down in 2020, new refinery sulphur capacity will nevertheless form the bulk of new additions to sulphur production over the next few years. But delays to projects on both the supply and demand sides could tip a fairly balanced market in either direction.

Meena Chauhan, Head of Sulphur and Sulphuric Acid Research, Argus Media, assesses price trends and the market outlook for sulphur.

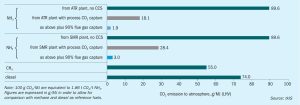

Reducing the carbon footprint in the synthesis of chemicals is a new global challenge as the world works towards providing sustainable products designed to minimise their environmental impacts throughout their whole lifecycle. This article looks at the role of blue technologies as part of a roadmap towards the decarbonisation of fuels and chemicals.

Judging by the pages of the project announcements in our news section, you’d be forgiven for thinking that the ammonia and methanol industries were all running off hydrogen generated from electrolysis, and that we had already entered an era of ‘clean’ chemical generation which did not require fossil fuels as a feedstock. Of course, while companies can naturally be forgiven for wanting to put the best public face on their green credentials, it does obscure the fact that for the moment 99% of syngas generation comes from natural gas, coal, and some coke or naphtha.

Although the urea market has weathered the pandemic relatively well, a significant amount of new capacity is due to come on-stream in the next year or so, and could keep prices depressed unless more Chinese capacity closes.

Gas availability and pricing continues to affect ammonia and methanol output from Trinidad, while Venezuela struggles with sanctions and political instability.

Hans Vrijenhoef has stepped down as Chief Executive Officer of Proton Ventures with immediate effect. He will continue to serve as non-executive chairman of the management board for at least another three years to support the growth of the existing business of green ammonia production technologies. Paul Baan succeeded Hans Vrijenhoef as of April 1st, 2021. Baan has served in leadership positions at Ørsted and EON. He is an engineer by background who has a strong understanding of Power to X technology and business cases.