The year ahead: affordability and availability concerns

We look ahead at fertilizer industry prospects for the next 12 months, including the key economic and agricultural drivers likely to shape the market during 2022.

We look ahead at fertilizer industry prospects for the next 12 months, including the key economic and agricultural drivers likely to shape the market during 2022.

Market Insight courtesy of Argus Media

New low-cost metal oxide solid scavengers for hydrogen sulphide (H2 S) removal from wet and dry natural gas have been developed and deployed at commercial scale. The desulphurisation process uses a proprietary sorbent chemistry to achieve a high sulphur capacity and removal efficiency. G. Alptekin, F. Kugler and M. Schaefer of SulfaTrap LLC describe the new technology and its performance.

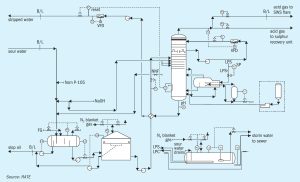

M. Rameshni and S. Santo of RATE discuss different sour water stripping gas processing options, depending on contaminants in the sour water streams and site-specific requirements.

Anglo American plc has announced a number of senior leadership changes. Seamus French has decided to leave Anglo American at the end of 2021 after 14 years with the company and will be replaced as CEO of Bulk Commodities by Themba Mkhwanazi , currently CEO of Kumba Iron Ore. Mpumi Zikalala , currently managing director of De Beers Managed Operations, has been appointed as CEO of Kumba. Both appointments will take effect on 1st January 2022. Mpumi’s successor at De Beers Managed Operations will be confirmed in due course.

The Valkyrie™ process was first introduced as a reborn version of redox technology for treating H2 S in natural gas processing.In this article Streamline Innovations Inc. highlights some of the new developments and successful applications of the Valkyrie process and its redox technology, in both gas and water streams.

Developments in sulphuric acid technology and engineering know-how are highlighted by recent project case studies from DuPont Clean Technologies, Metso Outotec and thyssenkrupp Uhde.

Lithium-boron miner ioneer Ltd has awarded DuPont Clean Technologies a contract for the license, engineering, and supply of proprietary equipment for a planned sulphuric acid plant at the company’s Rhyolite Ridge project in Nevada. DuPont will work with engineering partner SNC-Lavalin on the plant design, using MECS® sulphuric acid technology for the 3,500 t/d sulphur-burning unit, as well as controls that limit emissions to among the lowest in the world for this type of facility. DuPont will also supply its latest generation MECSSuper GEAR® ™ catalyst and other critical proprietary equipment. The contract is conditional on a final investment decision by the ioneer board of directors.

Considering the current shift to produce biofuels instead of conventional oil products, M. van Son of Comprimo discusses the impact that this may have on the ability to process the sour water acid gas streams produced in existing or new sour water strippers.

Although the number of new sour gas developments has slowed in recent years compared to the large boost of the previous decade, sour gas projects continue to be a major source of new sulphur production.