Fertilizer Industry News Roundup

Mining major Anglo American is to invest up to $4 billion to complete its Wood-smith mine project in the UK.

Mining major Anglo American is to invest up to $4 billion to complete its Wood-smith mine project in the UK.

A complete listing of all articles and news items that appeared in Nitrogen+Syngas magazine during 2022.

A complete listing of all articles and news items that appeared in Sulphur magazine during 2022.

Ammonia prices registered another week of losses at the start of January, with supply options continuing to outweigh demand in most regions. Prices have been falling steadily for the past twelve weeks, as the market rebalances after production curtailments across Europe for much of 2022. Steady falls in gas pricing over the past few weeks have put production costs firmly below today’s import price, with European production now scheduled to ramp up at many plants this month.

The past year has been a difficult, even disastrous one for Europe’s fertilizer producers. High natural gas prices have kept plants shuttered, with 70% of the continent’s ammonia production shut down at times. It remains uncertain how much of this will return to production this year, or indeed ever.

Sulphur run-down lines are typically sized by referencing past projects and ‘rules of thumb’. Very little analysis is performed to identify the impacts of slope, fittings, valves, etc. It is critical to maintain an open vapour path from the condenser to the sealing device. CSI has observed problems in the field which appear to be caused by undersized run-down lines and has developed a method of predicting the liquid level in a run-down line that considers the most common elements.

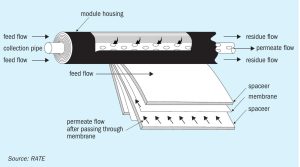

CO2 emission abatement strategies have become increasingly important as the world strives to combat global climate change. RATE discusses carbon capture options available for sulphur recovery units.

The world has seen a number of hydrogen explosions in double absorption plants mostly in the intermediate absorption tower (IAT). To review this increase and to determine the causes, an International Hydrogen Safety Workgroup was formed including major acid plant contractors, major acid producers, and consultants in the sulphuric acid arena. Davis & Associates Consulting explores some of the findings.

Last year attention was drawn to the potential for large scale decarbonisation to leave the world short of the key resources of sulphur, and hence sulphuric acid. But is there a global sulphur shortage on the distant horizon?

Almalyk Mining and Metallurgical Company (AMMC) has awarded Metso Outotec a euro 70 million order for the delivery of two sulphuric acid plants to be built for AMMC’s zinc roasting facility in Almalyk, Uzbekistan. Metso Outotec’s scope of delivery includes the design and delivery of Planet Positive equipment for two gas cleaning and sulphuric acid plants, which will process all off-gases from the zinc roasters into industrial-grade sulphuric acid. In addition, Metso Outotec will deliver utility facilities, such as a common cooling tower system and a common air compressor system.