Sulphur 422 Jan-Feb 2026

28 January 2026

Sulphur concrete sleepers: durable and reliable

MATERIALS OF CONSTRUCTION

Sulphur concrete sleepers: durable and reliable

Thiotrack sulphur concrete sleepers combine high mechanical performance with true circularity, validated by over a decade of field experience and rigorous independent testing. Denis Coppieters of Thiotrack reports on the key features and successful performance of Thiotrack sulphur concrete sleepers, offering high fatigue endurance with a truly reversible circular binder.

Infrastructure managers are increasingly seeking materials that deliver high mechanical performance and authentic end-of-life circularity. Railway networks worldwide face mounting pressure to reduce carbon footprints while maintaining safety and reliability. Conventional cement-based sleepers have served for decades, but their environmental impact and limited recyclability pose challenges for a sustainable future. Thiotrack sulphur concrete sleepers offer a breakthrough: prestressed elements produced at industrial scale, delivering 60 to 80 MPa compressive strength and validated through extended fatigue testing to 5 million cycles – far beyond the 2 million cycles required by EN standards.

The key differentiator lies in the reversible binder: sulphur solidifies by cooling rather than hydration, enabling closed-loop recycling through melting, separation of steel components, and remoulding into new sleepers.

Thiotrack’s journey began with its first sleepers produced in 2013, installed in track in 2014, and still performing successfully today – proof of durability and long-term reliability.

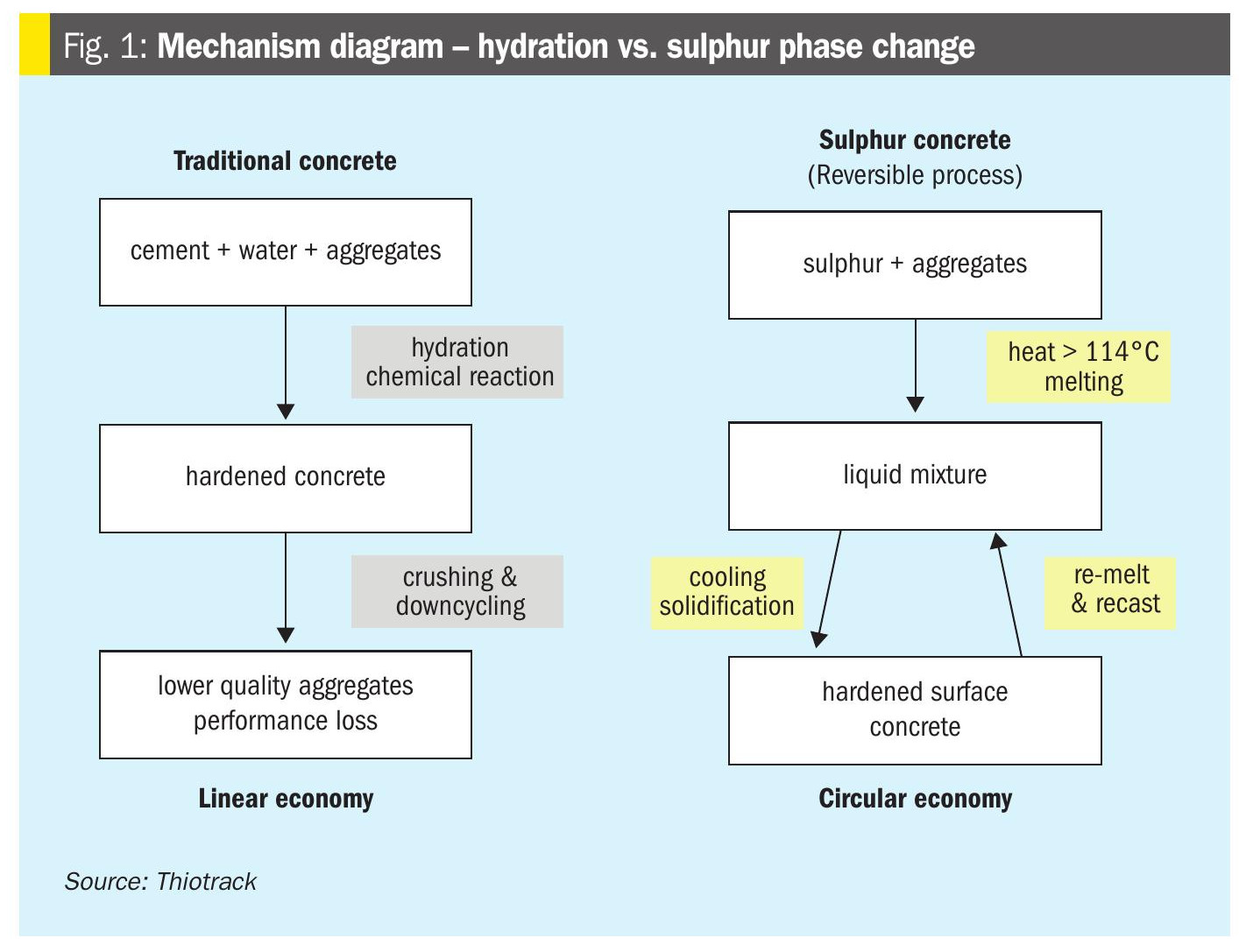

From hydration to phase change: Why sulphur enables circularity

Conventional concrete hardens through irreversible hydration of cement, making recycling complex and often limited to downcycling. Sulphur concrete, by contrast, is thermoplastic: sulphur melts at ~114°C and solidifies upon cooling, a purely physical phase change. This unique mechanism creates a dense, low-absorption matrix with excellent chemical resistance and allows end-of-life sleepers to be re-melted and re-formed without loss of performance (see Fig. 1).

Industrial manufacturing: Familiar geometry, faster process

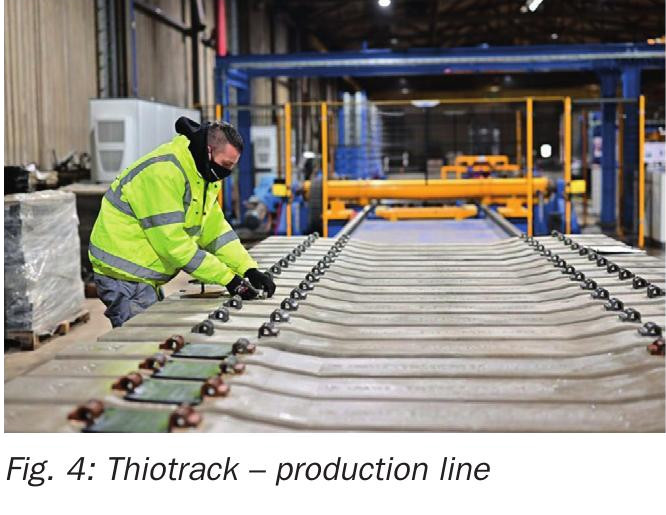

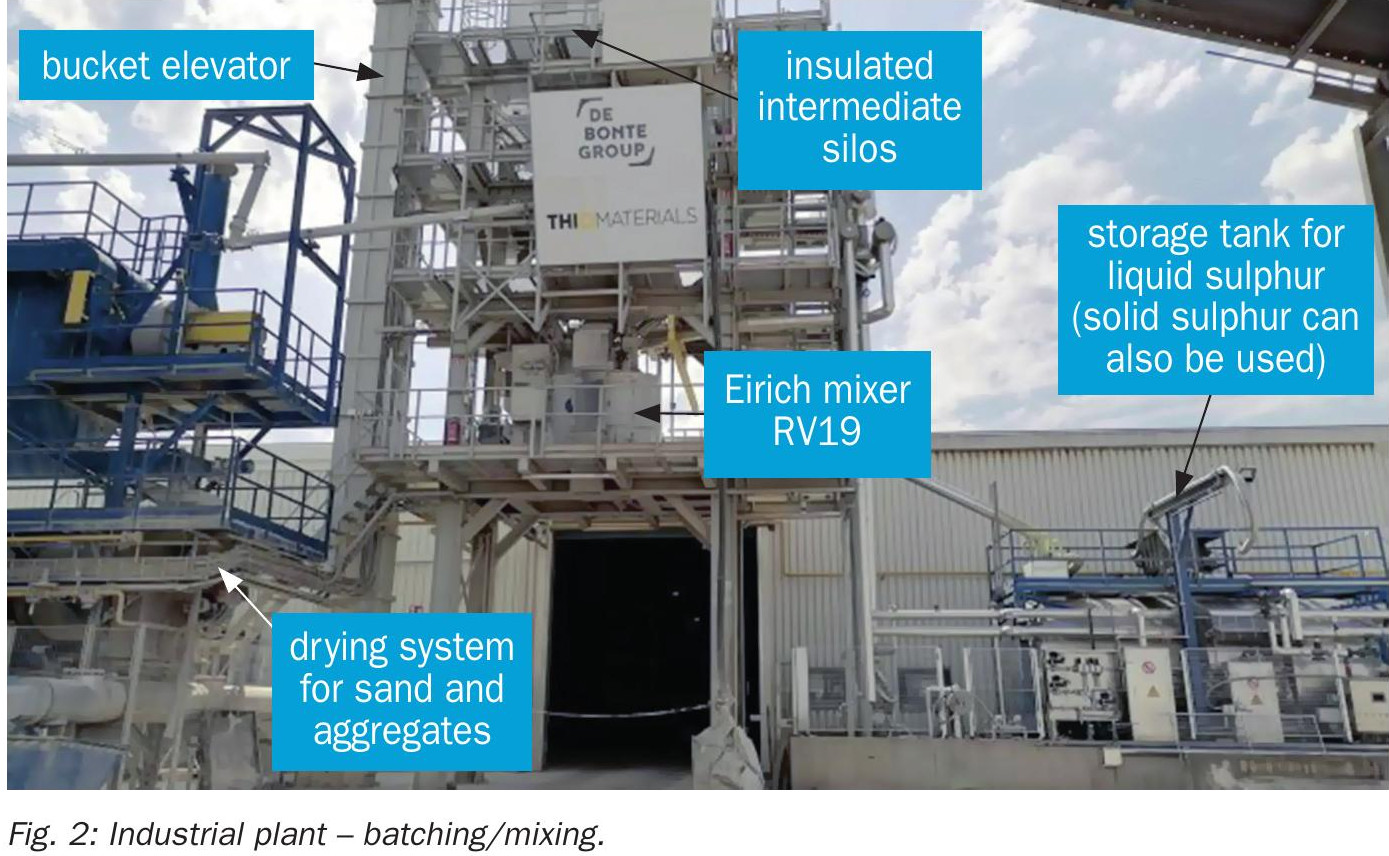

Thiotrack sleepers are produced on prestressing lines similar to those used for cement concrete (Fig. 2).

Key process steps:

- Aggregates preheated to ~135–140°C

- Molten sulphur blended and cast into preheated moulds

- Demoulding in 2 to 3 hours (vs. 8 to 24 hours for cement curing)

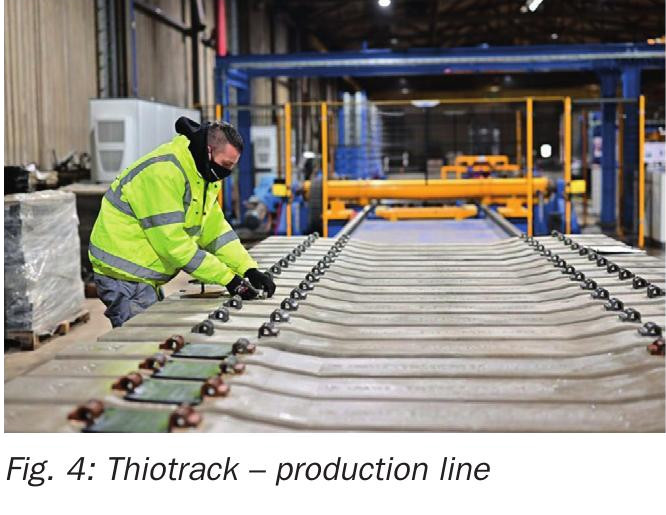

This short cycle accelerates production and reduces energy for curing. The Baudour (Belgium) factory operates at 10 t/h, producing up to 120,000 sleepers/year (Fig. 4) plus sulphur concrete pipes, using standard prestressing reinforcement and fastening inserts.

Mechanical performance: Strength and fatigue endurance

Compressive strength: Thiotrack sleepers consistently achieve 60–80 MPa, exceeding EN 13230 requirements and European network specifications.

Fatigue resistance: Independent testing (Fig. 3) by Technical University of Munich (TUM) on a B70 sleeper confirmed exceptional endurance: Normative requirement: 2 million cycles

- Thiotrack result: 5 million cycles, crack widths of 0.06 mm (loaded) and 0.03 mm (unloaded) (limits: ≤0.10 mm and ≤0.05 mm)

- Ultimate load measured after 5 million cycles: FrB > 394 kN, no fracture (requirement: >384 kN)

This performance demonstrates a service life comparable or superior to traditional concrete sleepers.

Durability and field experience

Thiotrack sleepers have been deployed across Europe (Fig. 5): Infrabel (Belgium), ProRail (Netherlands), SNCF Réseau (France). Feedback confirms compatibility with standard maintenance, including thermite welding, and highlights advantages in low water absorption, acid resistance, and abrasion resistance – ideal for harsh environments and coastal conditions.

The reverse process: True closed-loop recycling

Sulphur’s thermoplastic nature enables a fully reversible lifecycle:

- Heat the sleeper to liquefy sulphur.

- Separate prestressing wires and inserts.

- Recast new sleepers using recovered materials.

Lab and field trials confirm equivalent performance for recycled sleepers. SNCF has operated recycled Thiotrack sleepers in track since 2020, validating circularity in real-world conditions.

Environmental perspective

Replacing cement with sulphur eliminates clinker-related CO2 emissions and water use. While 85% of the mix (aggregates + sand) remains identical to cement concrete, the binder changes:

- Cement sleepers: ~15% cement

- Sulphur sleepers: ~10% sulphur

Sulphur’s carbon footprint (from refinery recovery via Claus process) is estimated at 232 to 276 kg CO2 eq per tonne (Journal of Environmental Chemical Engineering, April 2024). In comparison, Portland cement averages ~748 kg CO2 eq per tonne (Infociments, 2024).

Result

Replacing cement sleepers with sulphur sleepers reduces binder-level CO2 emissions by ~70%, and overall sleeper footprint roughly half that of a CEM I cement sleeper, even accounting for heating energy during production.

Pipes: A complementary application

Thiotrack also manufactures sulphur concrete pipes (Fig. 5) for sewerage, leveraging the same binder technology for acid and abrasion resistance. This diversification reinforces the robustness of sulphur concrete for infrastructure.

Outlook: Partnerships for scale

Thiotrack invites rail operators, infrastructure managers, and industry partners to collaborate on pilot projects, regional production models, and joint testing programs – accelerating the transition to cement-free, circular sleepers.