Nitrogen+Syngas 399 Jan-Feb 2026

26 January 2026

Redefining economical small-scale methanol production

METHANOL PRODUCTION

Redefining economical small-scale methanol production

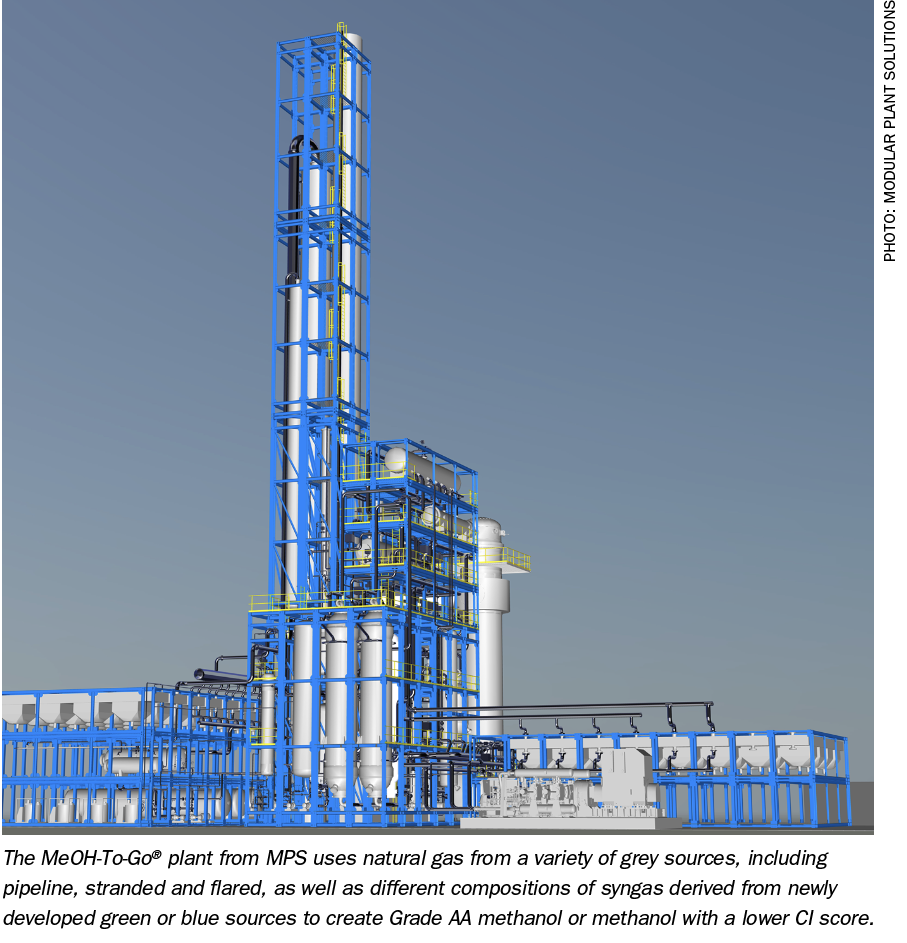

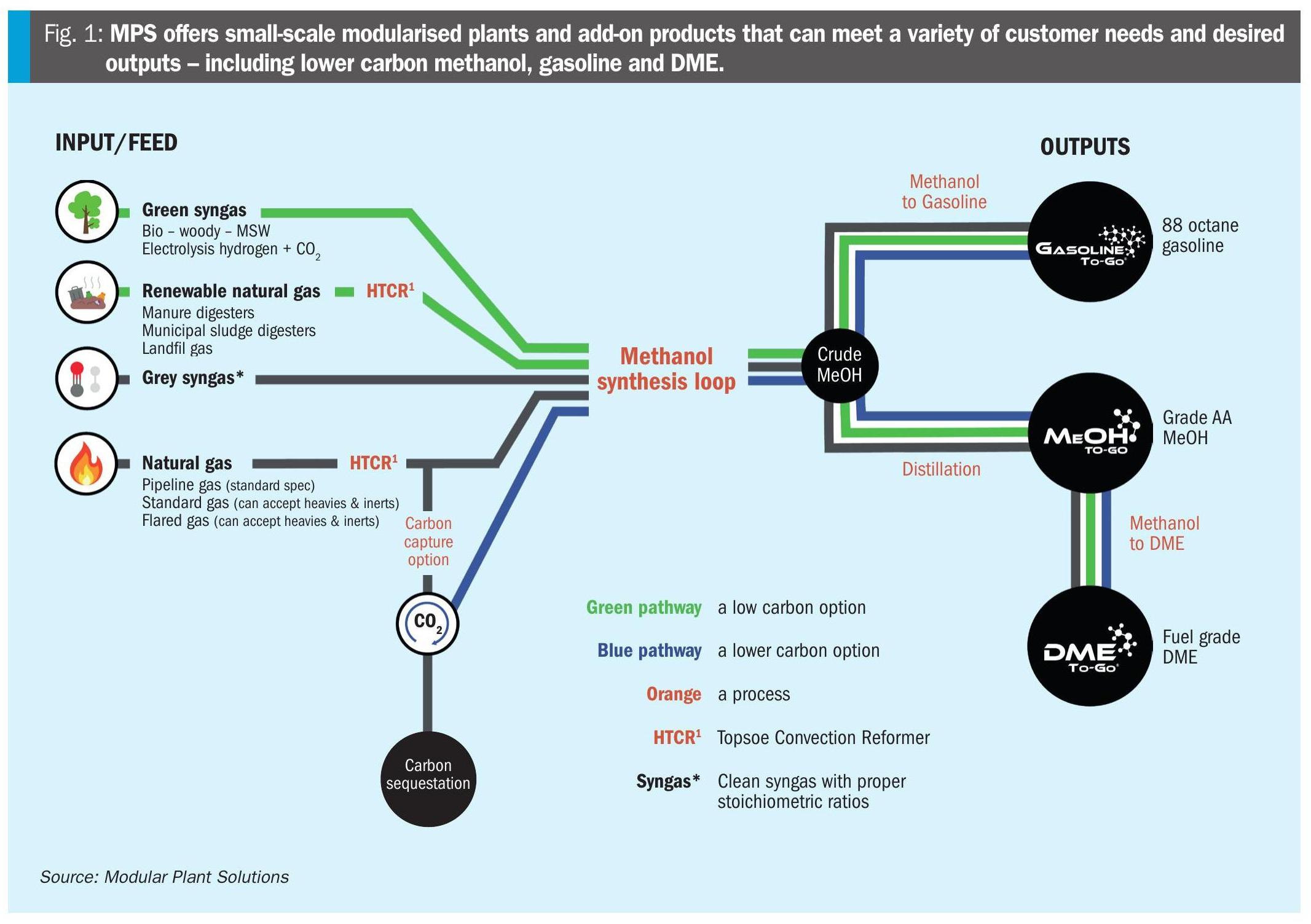

Traditionally, methanol production has relied on large-scale facilities designed for high-volume output, high capital costs, and long project timelines. However, the energy industry faces a growing need for regionalised, flexible, and lower-carbon solutions. Russell Hillenburg of Modular Plant Solutions (MPS) introduces the MeOH-To-Go® plant, a new approach to methanol production through small-scale, modularised plant design.

In the global drive toward sustainable and decentralised energy production, methanol continues to prove its versatility as both a platform chemical and an increasingly important low-carbon fuel. Modular Plant Solutions’ flagship plant, the MeOH-To-Go® plant, brings a new approach to methanol production through small-scale, modularised plant design. Built on a patented system, with modular frames that conform to the ISO-1496/CSC container standard, MeOH-To-Go® enables economical methanol production with a variety of feedstock possibilities, from remote stranded gas fields to renewable natural gas and syngas sources.

Rethinking scale: From world-class to modular-class

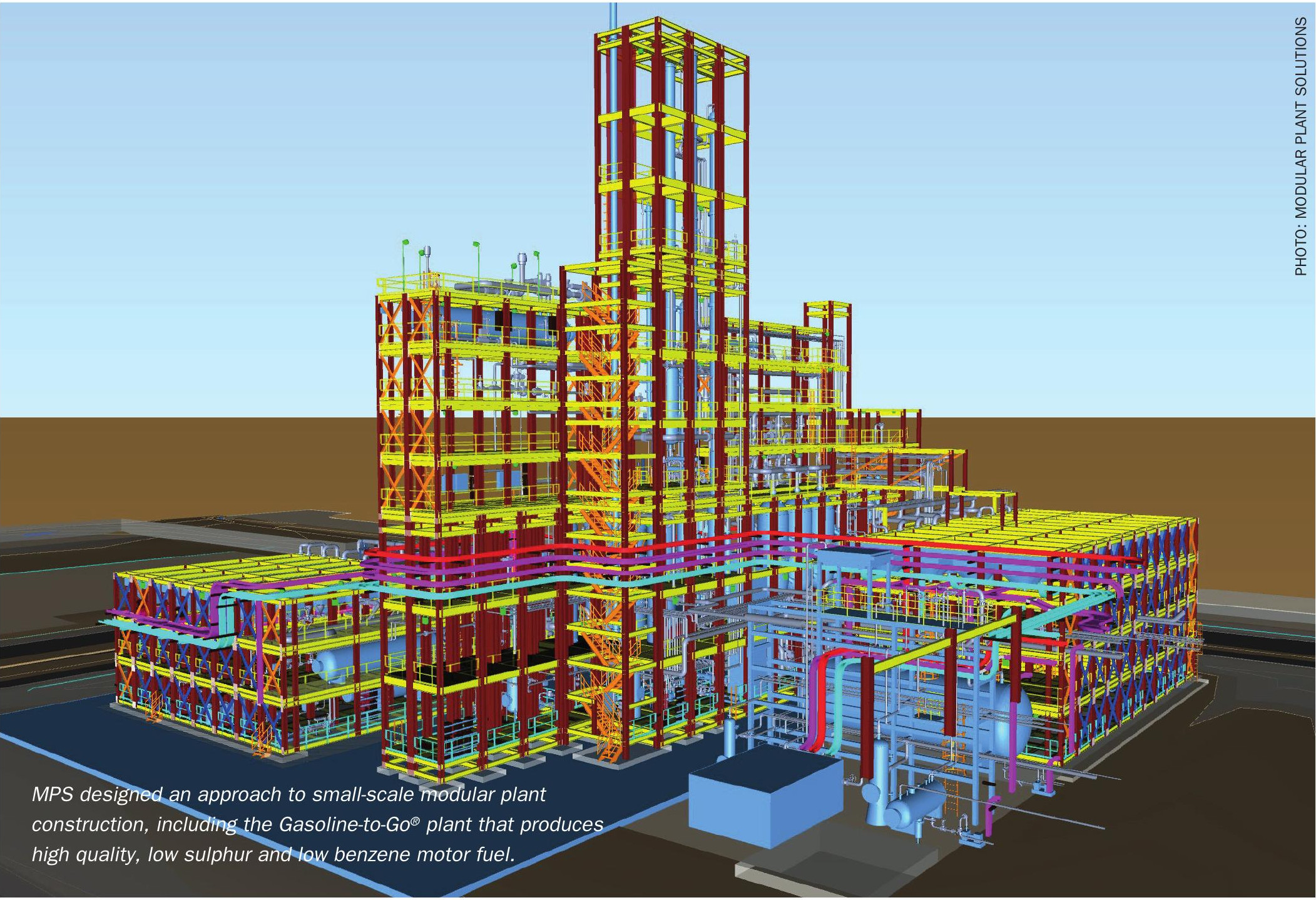

The MeOH-To-Go® plant is roughly one-twentieth the size of a conventional world-scale facility, yet it delivers commercial-grade AA methanol production through a highly engineered, modular system. Each module is prefabricated within frames the size of standardised ISO shipping containers, allowing plant module transport by truck, rail, or cargo ship and on-site assembly.

This approach offers multiple advantages:

- Predictable capital expenditure: Modular fabrication ensures repeatable designs and controlled costs.

- Accelerated deployment: Parallel manufacturing and plug-and-play assembly reduce project timelines.

- Reduced site risk: Minimal on-site construction lowers exposure to weather delays and labor shortages.

- Consistent quality: Factory-built modules ensure repeatable performance and easier maintenance.

By contrast, traditional methanol plants require extensive site development, field fabrication, and long commissioning phases. MeOH-To-Go® shifts much of that work off-site, an advantage that improves economics for smaller-scale projects.

From flaring to fuel: Unlocking value in stranded gas

A key design driver for MeOH-To-Go® was the global challenge of stranded and flared natural gas. According to World Bank data, roughly 148 billion cubic metres of associated gas is flared annually – a waste of valuable resources and a significant contributor to greenhouse gas emissions.

Because MeOH-To-Go® plants can be transported and assembled in remote areas, they provide an economically viable way to capture, convert and monetise stranded gas. By turning this wasted feedstock into methanol, operators can reduce flaring, generate marketable products, and support local economic activity – all within a smaller carbon footprint.

The plant’s feedstock flexibility also opens opportunities beyond stranded gas. MeOH-To-Go® can utilise grey natural gas, renewable natural gas (RNG), or syngas from green or blue sources to produce Grade AA methanol, either grey or low-carbon. This adaptability allows operators to align production with their feedstock availability, carbon reduction targets and market strategy.

Technology inside the box: The MeOH-To-Go® design

At the core of the MeOH-To-Go® concept is its patented modular structure (U.S. Patent 11952769, 2024), which integrates process and structural engineering within ISO-1496 compatible frames. Beyond simply “fitting equipment into boxes,” this patented design allows for vertical orientation of modules and stacking of tall process components such as distillation columns – a first for a process plant based on ISO-1496 compatible frames.

This vertical module integration maximises space efficiency while maintaining full process capability. The ISO-1496 compatible modules also simplify shipping and on-site installation.

The MeOH-To-Go® plant includes all key process elements for methanol synthesis – reforming, compression, synthesis loop, distillation, and utilities – compactly arranged for transport and field assembly. The plant utilises Topsoe’s high-efficiency convection reformer HTCR technology, and each module arrives pre-piped, pre-wired, and factory-tested to minimise commissioning time.

Modularisation as a strategy, not a scale-down

While “modularisation” has become a common buzzword in plant design, the approach with MeOH-To-Go® represents true modular engineering, not simply a scaled-down replica of larger systems. By standardising design and fabrication around ISO dimensions, MeOH-To-Go® achieves repeatability and scalability across multiple plant configurations.

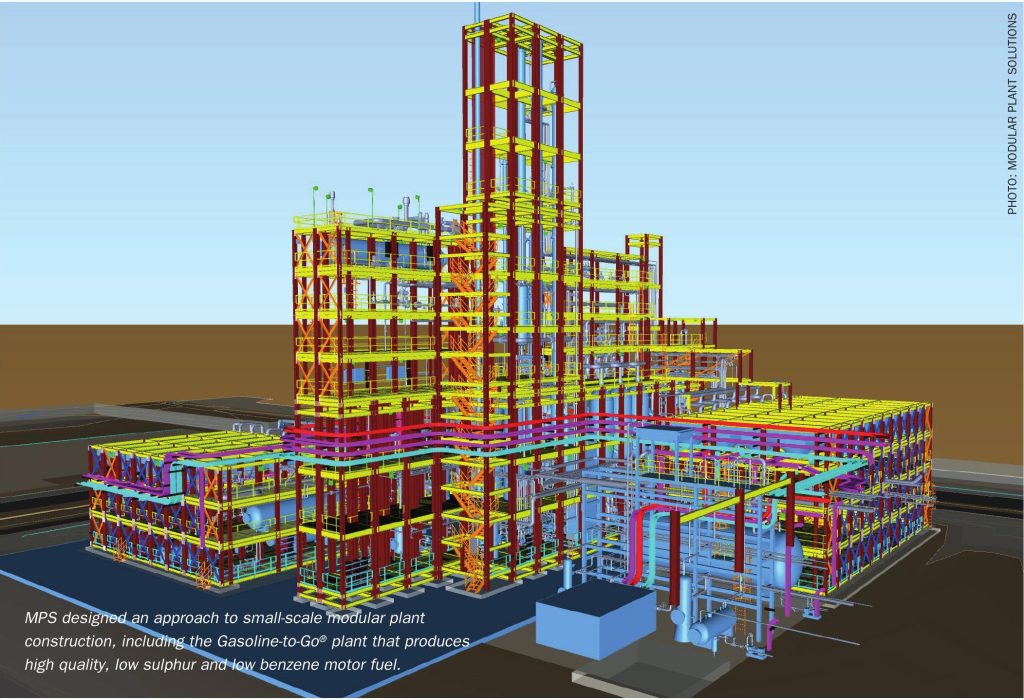

This strategy extends to more than methanol alone. MPS’s modular approach can integrate additional back-end processing units, including:

- Gasoline-To-Go®, for producing 88-octane gasoline and LPG directly from syngas or natural gas.

- DME-To-Go®, for producing dimethyl ether (DME), a clean-burning diesel alternative.

These pre-engineered add-ons allow customers to tailor production to market needs, for example, a methanol plant near a port that later expands to produce gasoline or low-carbon DME.

Driving economical and sustainable methanol production

One of the primary challenges in small-scale methanol production has always been the balance between capital cost and operating efficiency. Historically, small plants could not compete on per-tonne economics with mega-scale facilities. MeOH-To-Go® closes that gap.

Through modular construction, reduced labour requirements, and standardised equipment, the plant lowers total installed cost. The system’s self-sufficient utilities minimise dependence on external infrastructure, enabling stand-alone operation – ideal for remote or distributed applications.

Furthermore, MeOH-To-Go® can integrate carbon capture or sequestration modules, supporting a range of low-carbon pathways. This makes it a compelling technology for companies seeking to align with decarbonisation mandates while expanding into new markets for renewable fuels and sustainable chemicals.

Licensing and industry collaboration

Beyond building and delivering turnkey MeOH-To-Go® plants, MPS has expanded its strategy through technology licensing and modularisation services. This enables energy companies and developers to apply MPS’s patented modular structural system to their own small-scale projects – whether for methanol, hydrogen, ammonia, other syngas derivatives or products.

Licensing partners benefit from MPS’s engineering expertise, patented modular approach and process integration experience, reducing design risk and accelerating deployment. As demand grows for localised production of fuels and chemicals, these partnerships make small-scale modularisation a practical reality across the energy sector.

A path forward for decentralised syngas applications

Methanol’s versatility – as a hydrogen carrier, fuel component, and key building block chemical – makes it an important part of the shift toward a cleaner, more sustainable energy future. Yet the industry’s ability to harness that potential depends on more flexible production strategies.

By making methanol production economical at small-scale, MeOH-To-Go® unlocks new routes for regional energy independence and chemical manufacturing. The plant’s modular architecture supports rapid deployment in diverse environments, from oilfields and ports to biogas sites and industrial parks.

Conclusion

The MeOH-To-Go® plant represents more than a new way to build methanol plants – it represents a new way to think about process engineering itself. By combining modularisation, flexibility, and sustainability, MPS has redefined the economics of small-scale methanol production.

As the syngas and nitrogen industries evolve toward cleaner and more adaptable solutions, technologies like MeOH-To-Go® can help bridge the gap between intent and practical deployment.

MPS shows that smaller can indeed be smarter and more sustainable. MPS is working to bring some new applications online in the near future, leveraging various green feedstocks to produce methanol to fuel.