Fertilizer International 530 Jan-Feb 2026

23 January 2026

AGI delivers first fertilizer tower system in Brazil

Introduction

IntroductionWith agricultural production booming, Brazil’s powerhouse status is being hampered by significant storage infrastructure deficits – not only for grain, but for crucial inputs like fertilizer. AGI (Ag Growth International), as a global leader in the grain, fertilizer, feed, seed, and food sectors, is well positioned to engineer solutions that can address these deficits and help transform the country’s agricultural sector.

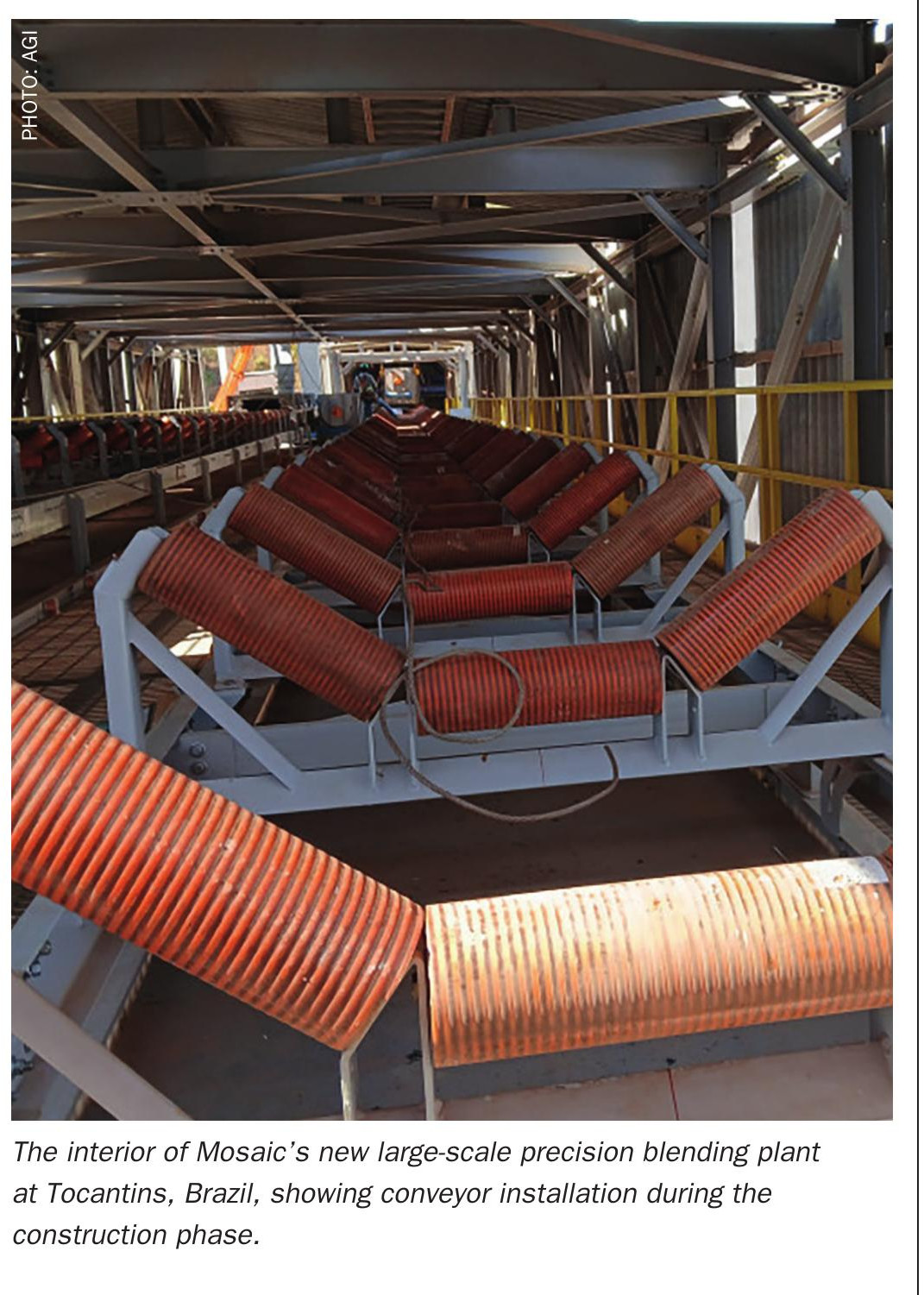

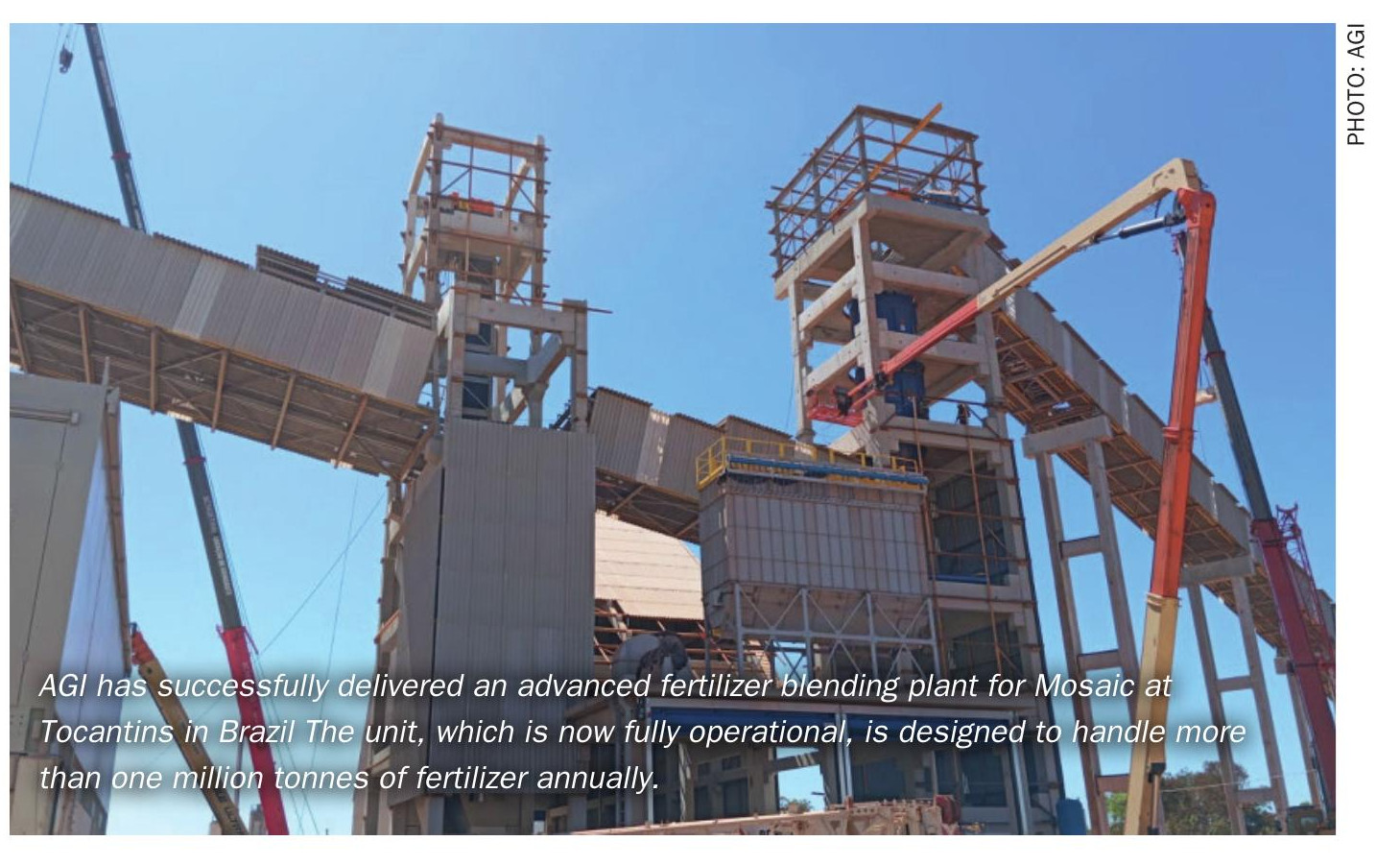

This year, AGI successfully delivered its first vertical fertilizer tower blending system in Brazil for Mosaic at Tocantins, marking a major milestone in its strategic expansion into high-growth agricultural markets. This technologically advanced project showcases AGI’s ability to collaborate with customers and adapt and innovate in response to regional needs.

Strategic expansion into Brazil’s fertilizer market

“Brazil is one of the world’s largest agricultural producers, consuming over 46 million tonnes of fertilizer annually with growth projected at 49 million tonnes by 2030,” says Robson Engers, AGI’s Director of Operations. “Our customer – already holding 20% of the Brazilian fertilizer market – sought to expand its footprint in the country’s northern agricultural frontier. Our partnership underscores a shared commitment to innovation, efficiency and market responsiveness.”

Located in a remote region around 2,000 kilometres from AGI’s Sao Paulo base, the new plant is one of the most advanced fertilizer blending facilities in Brazil. The project includes a complete receiving, blending and load-out system with a fully automated process managed by the customer. The facility is designed to handle more than one million tonnes of fertilizer annually and includes more than 100,000 tonnes of storage capacity.

Engineering innovation and customisation

This project, says Engers, pushed AGI beyond its standard solutions, requiring extensive custom engineering and new product development. Key innovations include:

• Custom bucket elevator leg: Designed with reinforced mild steel casing and conveyor belt side panels, this feature reduces material costs while maintaining structural integrity – offering a cost-effective and durable solution tailored to the customer’s unloading systems.

• Liquid impregnation system: Integrates liquid additives into dry fertilizer, enhancing nutrient delivery and crop yield – supporting sustainable agriculture and better farm outcomes.

• Dosing bins and scale hoppers: Engineered using finite element analysis (FEA) to ensure structural integrity and precise metering, essential for accurate blending and operational reliability.

• Modular construction: Due to the remote location, systems were designed for sectional transport, ensuring seamless integration and minimal material loss.

Collaboration and risk mitigation

According to Engers, the project’s success was driven by AGI’s Technical Risk Summary and Plan (TRSP) process, which identified and mitigated potential risks early in the project lifecycle.

“Cross-functional collaboration between global product management, engineering and local Brazilian teams was instrumental in navigating challenges related to logistics, weather and cost competitiveness,” he adds.

A model for future product transfers

This project exemplifies AGI’s evolving approach to technology transfers – not as simple replications, but as unique opportunities for market-specific innovation.

“The lessons learned and technologies developed for our customer in Brazil are now being considered for reverse transfer into North America and other global markets,” says Engers.

As AGI continues to refine its global product transfer strategy, the Mosaic project stands as a benchmark for future initiatives.

“With a focus on listening to local market needs, fostering cross-border collaboration and embracing innovation, AGI is well-positioned to lead the next wave of agricultural infrastructure development worldwide,” sums up Engers.