Nitrogen+Syngas 399 Jan-Feb 2026

22 January 2026

Expanding the melamine horizon with uLEM-N technology

MELAMINE TECHNOLOGY

Expanding the melamine horizon with uLEM-N technology

CASALE has expanded its melamine technololgy portfolio with uLEM-N, a market-driven technology development, which retains the industrial proven high-pressure synthesis section and urea-based offgas scrubbing of the LEM® and uLEM® technologies, and uses an innovative purification section which enhances the process reliability while minimising the energy consumption.

The high-pressure melamine technologies LEM® (Low Energy Melamine) and uLEM® (ultra-Low Energy Melamine) have been on the market since 2013, when CASALE acquired the former Borealis HP melamine technology1,2. Their key features include urea-based offgas scrubbing3, which generates high-temperature and high-pressure anhydrous offgas, and the use of sodium hydroxide to create the alkaline conditions required for melamine purification. These technologies ensure the consistent production of high-quality melamine with minimal energy consumption, but they require a NaOH solution as a consumable chemical. In some regions (for example, Northern China) sourcing these chemicals can be difficult or costly.

Although methods exist to minimise sodium hydroxide consumption4, in some regions the complete elimination of NaOH (even for initial plant filling or small makeup streams) may be required for the technology to be economically viable. Using ammonia in place of sodium hydroxide is well known in melamine production, and applying ammonia in an innovative way has produced a new process scheme. This new process, the latest addition to the CASALE HP melamine technology family, is called uLEM-N (ultraLow Energy Melamine – Ammonia).

Even though using sodium hydroxide instead of ammonia provides lower energy consumption and a simpler process, an optimised ammonia-based purification technology is a good compromise whenever the use of NaOH is uneconomical. The uLEM-N technology completes the CASALE melamine portfolio, enabling CASALE to recommend the most suitable solution on a case-by-case basis.

Although new, uLEM-N has already been selected for its first industrial application by Anhui Haoyuan Chemical Group, which will build a new 60,000 t/a melamine plant in Xinjiang Province (P.R. China)5.

uLEM-N technology overview

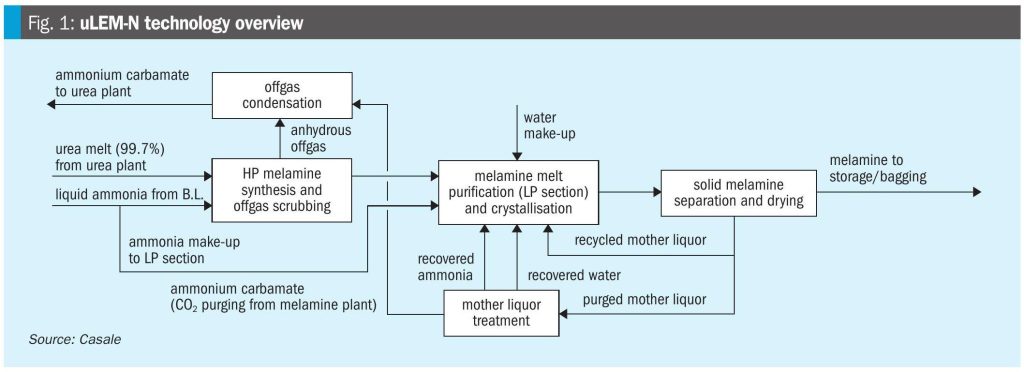

uLEM-N is a high-pressure (HP) technology in which melamine is produced in the liquid phase from urea. Alongside melamine, the process generates an offgas composed of ammonia and carbon dioxide. In this technology, melamine synthesis and offgas separation occur in the high-pressure section of the plant. The offgas is condensed to ammonium carbamate within the plant battery limits, producing low-pressure steam that is used in the same melamine plant. The melamine product is purified in the low-pressure (aqueous) section of the plant (Fig. 1). The basic environment required for the purification is ensured by an ammonia-water solution.

HP melamine synthesis

uLEM-N technology retains the same synthesis section used in the LEM® and uLEM® technologies1,2.

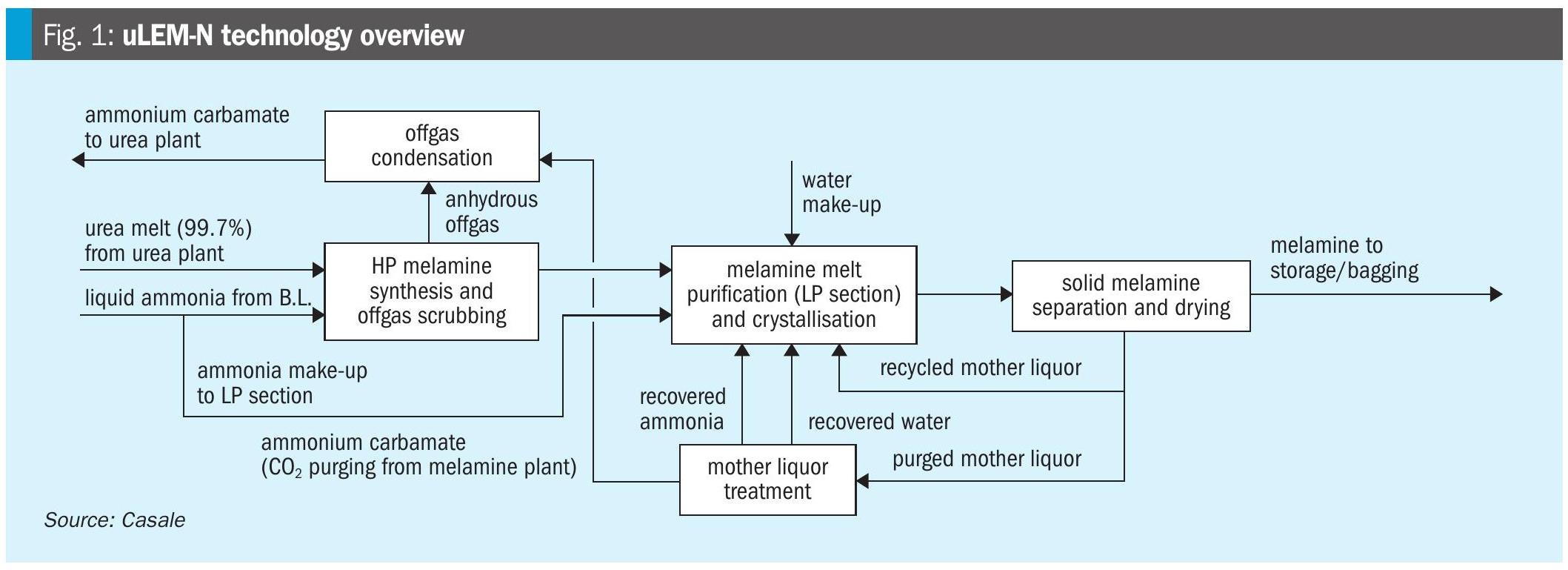

The HP section of a uLEM-N plant comprises a combined reactor6,7 and an offgas scrubber3, as shown in Fig. 2. The operating pressure is uniform throughout this section.

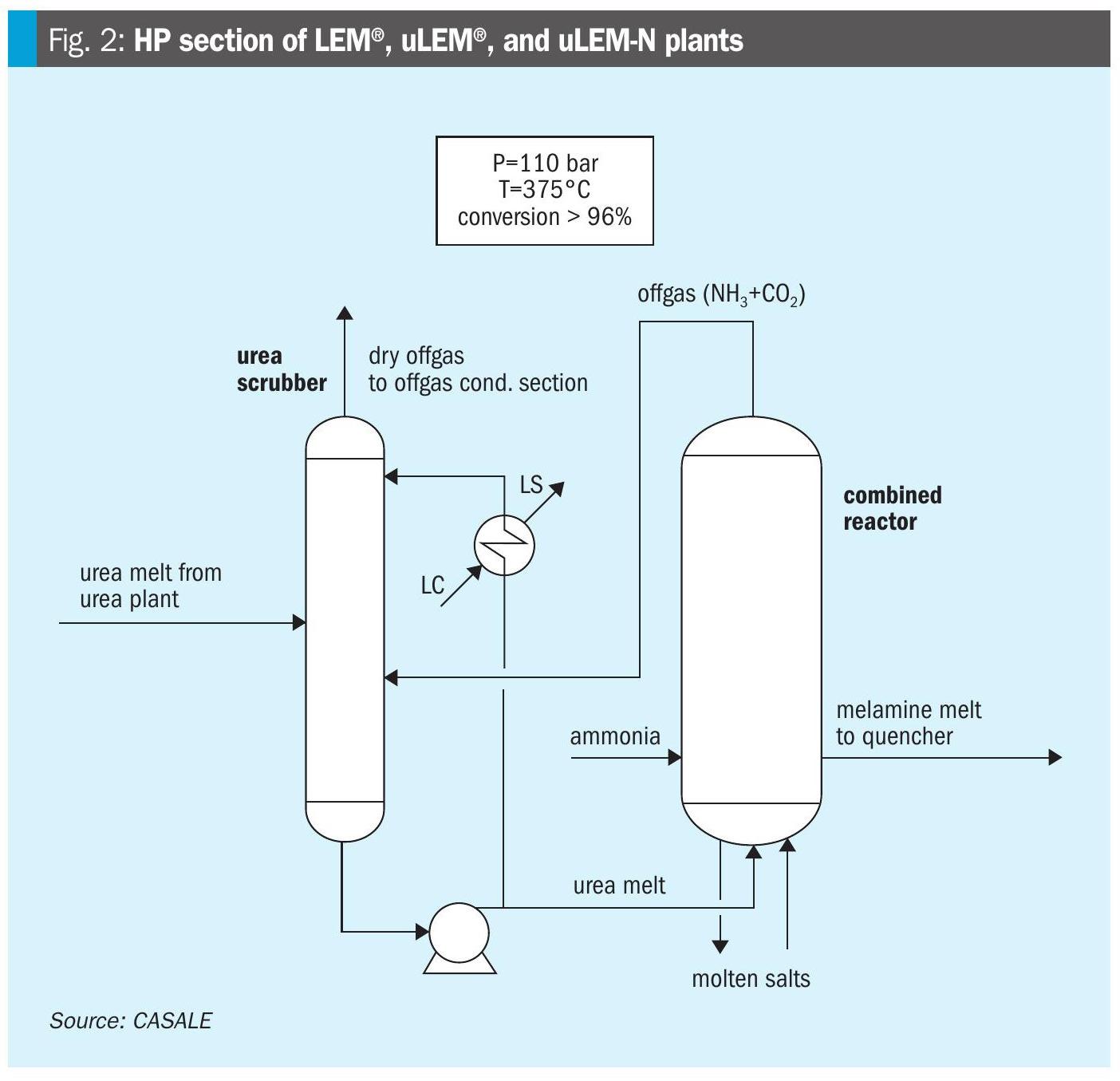

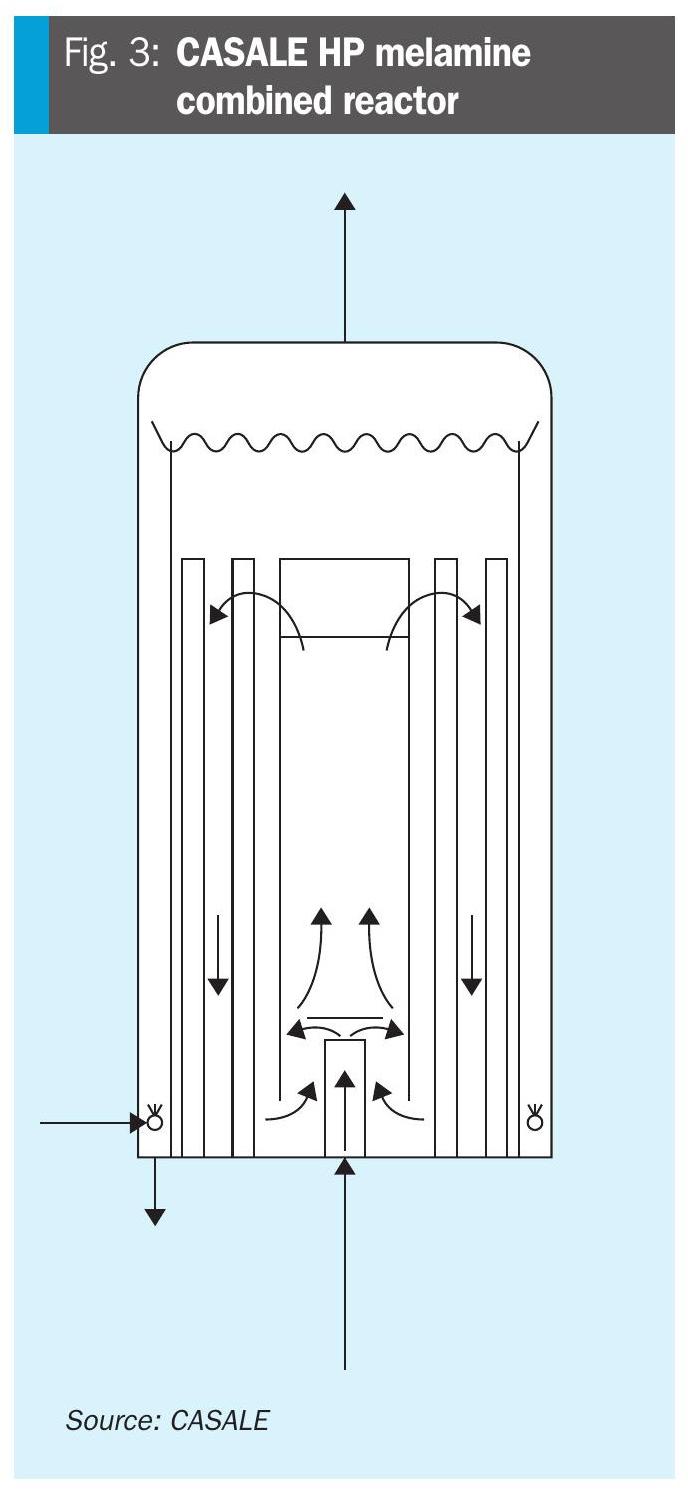

The combined HP melamine reactor consolidates the duties of the first and second reactors conventionally used in melamine plants into one piece of equipment. It consists of two coaxial reaction zones: a central reaction zone and an annular reaction (stripping) zone that surrounds the central zone (Fig. 3).

In the central reactor zone, the bulk conversion of urea to melamine is achieved, and the heat of reaction is supplied by circulating molten salts. In designing the combined reactor, the central reaction zone was not modified compared with the traditional first reactor.

The annular section of the combined reactor performs the function of the second reactor in the traditional dual-reactor configuration.

The offgas from the central reaction zone and the stripping gas from the annular zone are discharged from the top of the combined reactor and routed to the urea scrubber.

Reactor internals have been carefully designed to enhance the stripping process in the annular zone; consequently, the two reaction zones retain their distinct identities and functions even though they are combined in a single vessel. The combined reactor performs better than a sequence of two reactors because it uses the stripping volume more effectively than a standard second reactor.

The melamine HP combined reactor is the standard reactor in the LEM®/uLEM®/uLEM-N process schemes. On request,LEM®/uLEM® /uLEM-N can still be supplied with the traditional dual-reactor configuration.

In the urea scrubber, the offgas is washed by counter-current contact with molten urea. The primary objective of this washing is to remove melamine from the offgas before it is recycled to the urea plant.

Offgas scrubbing with molten urea is a distinctive feature of melamine technologies. CASALE has long-standing knowhow in designing and operating this type of scrubber in HP melamine plants, supported by industrial experience from operating plants.

Proper design of the scrubber and the heat exchanger3, and the correct selection of the urea circulating pump, require deep practical knowledge of plant operation and maintenance. Accurate simulation models for design and material selection are not commercially available8; therefore, operational data and experience are the foundation of the company’s expertise and enable the design of reliable urea-based offgas scrubbing units.

The first application of the scrubber dates back to the mid-1990s at the Castellanza plant in Italy (currently not in operation).

Following the Castellanza experience, upgraded scrubbers were installed first in Linz (2000) and then in Piesteritz (2004); both units remain in successful operation. Operation of the scrubbers at these plants enabled fine-tuning of operating parameters and optimisation of the equipment design. Three additional scrubbers have been designed and built for LEM® plants, two of which have been in service since 2019 and 2023, respectively.

Using urea for scrubbing permits heat recovery from the offgas within the melamine plant and yields a high-pressure, water-free stream of ammonia and carbon dioxide. This makes a CASALE LEM®/uLEM®/uLEM-N plant straightforward to integrate with a urea plant.

Furthermore, avoiding offgas separation from the melamine solution in the low-pressure section of the plant reduces overall steam consumption.

Melamine purification and separation

In the low-pressure section of a uLEM-N plant, the melamine melt is quenched, purified, and crystallised in an ammonia–water solution. Final steps include solid–liquid separation and drying.

Leveraging extensive knowledge of the purification chemistry when sodium hydroxide is used, together with a deep understanding of the performance of the established synthesis and offgas scrubbing configuration, the uLEM-N melamine purification and mother-liquor treatment strategies were developed to minimise energy consumption and ensure process reliability. Although uLEM-N inherently consumes more energy than its NaOH-based counterpart (i.e., uLEM®), it is well suited to regions where supplying caustic soda solution is difficult or expensive.

The primary difference between sodium hydroxide and ammonia is their basic strength. With this in mind, the uLEM-N purification scheme incorporates innovative features that minimise CO2 concentration in the melamine aqueous solution throughout the process, from quenching to crystallisation, thereby improving process reliability.

Industrial melamine production requires consistent manufacture of high quality product, which is achieved through robust purification schemes. CO2 – generated during melamine purification and mother-liquor thermal treatment from unreacted urea, oxyaminotriazines (OATs), and melamine hydrolysis – exerts an acidic effect that impacts systems using ammonia more severely than those using sodium hydroxide. For this reason, the uLEM-N process ensures that water recycled from the mother-liquor treatment back to melamine purification is free of dissolved CO2. This is accomplished without undue energy penalty through a purpose-built, proprietary design of the mother-liquor treatment.

Mother-liquor treatment comprises a series of distillation and thermal steps intended to recover ammonia for reuse, remove CO2 produced in the melamine plant (both LP purification and mother-liquor treatment sections), and destroy OATs. All water recovered by the mother-liquor treatment is recycled to the melamine process; consequently, uLEM-N operates as a zero liquid discharge (ZLD) process.

Although undesirable, OAT formation is unavoidable and is a primary reason for the mother-liquor treatment. OATs are produced in both the synthesis and purification sections and are kept in solution during crystallisation to prevent contamination of the final product. Their solubility in ammonia solutions is much lower than in sodium hydroxide solutions. Therefore, to avoid treating excessive mother-liquor flowrates (which depend on the maximum allowable OAT concentration and generation rate), uLEM-N purification operating parameters are selected to minimise OAT formation.

Commercial applications

CASALE LEM®/uLEM® technologies are currently used in five plants worldwide, with a total installed capacity of 250,000 t/a of melamine. Four of these plants are already in operation. The uLEM-N technology has been applied for a new 60,000 t/a plant; its basic engineering package was completed in 2025.

The commercial deployment of both NaOH-based and ammonia-based melamine processes demonstrates CASALE’s expertise in managing both technologies. This capability allows the company to recommend the most suitable solution for each client, taking into account the plant location and local utility and raw material costs.

Conclusions

uLEM-N was developed specifically for regions where supplying NaOH is difficult or costly. Although it inherently consumes more energy than its sister technology, uLEM® – a consequence of using ammonia instead of NaOH – uLEM-N still ensures consistent production of high-quality melamine and offers the lowest energy consumption and the best reliability to energy consumption ratio among ammonia-based purification technologies.

Furthermore, uLEM-N uses the proven HP section (melamine synthesis and urea-based offgas scrubbing) from its sister technologies, LEM® and uLEM®, thereby retaining the demonstrated reliability and durability of the process core.

With a comprehensive melamine technology portfolio, CASALE can address diverse client requirements and, leveraging its urea expertise, propose an optimised, tailormade integration of melamine production with a urea plant.

References