Sulphur 420 Sep-Oct 2025

15 September 2025

Unlock the true potential of your SRU

SRU REVAMPING

Unlock the true potential of your SRU

Jyoti Bist, Debopam Chaudhuri, Theresa Flood and Michiel Baerends of Fluor explore the versatile potential of oxygen enrichment for various revamp and debottlenecking opportunities. Oxygen enrichment not only serves as an obvious choice to significantly increase the sulphur processing capability of the unit with minimum plant modifications but also expands the sulphur plants operational flexibility allowing it to process a wide gamut of feed gas cocktails having challenging feed gas compositions, as this article will show via two separate case studies.

All crude oil contains some amount of sulphur compounds. These compounds range from the simplest form, namely hydrogen sulphide found in natural gas, through simple mercaptans compounds (R-S-H), to very complex molecules. These sulphur compounds pass through to the various distillate products in various degrees of concentration. If allowed to remain in the distillates, they have adverse effects on the environment; corrosive to equipment; and deactivate high-value catalysts of downstream processes. Therefore, sulphur treatment and recovery becomes inevitable.

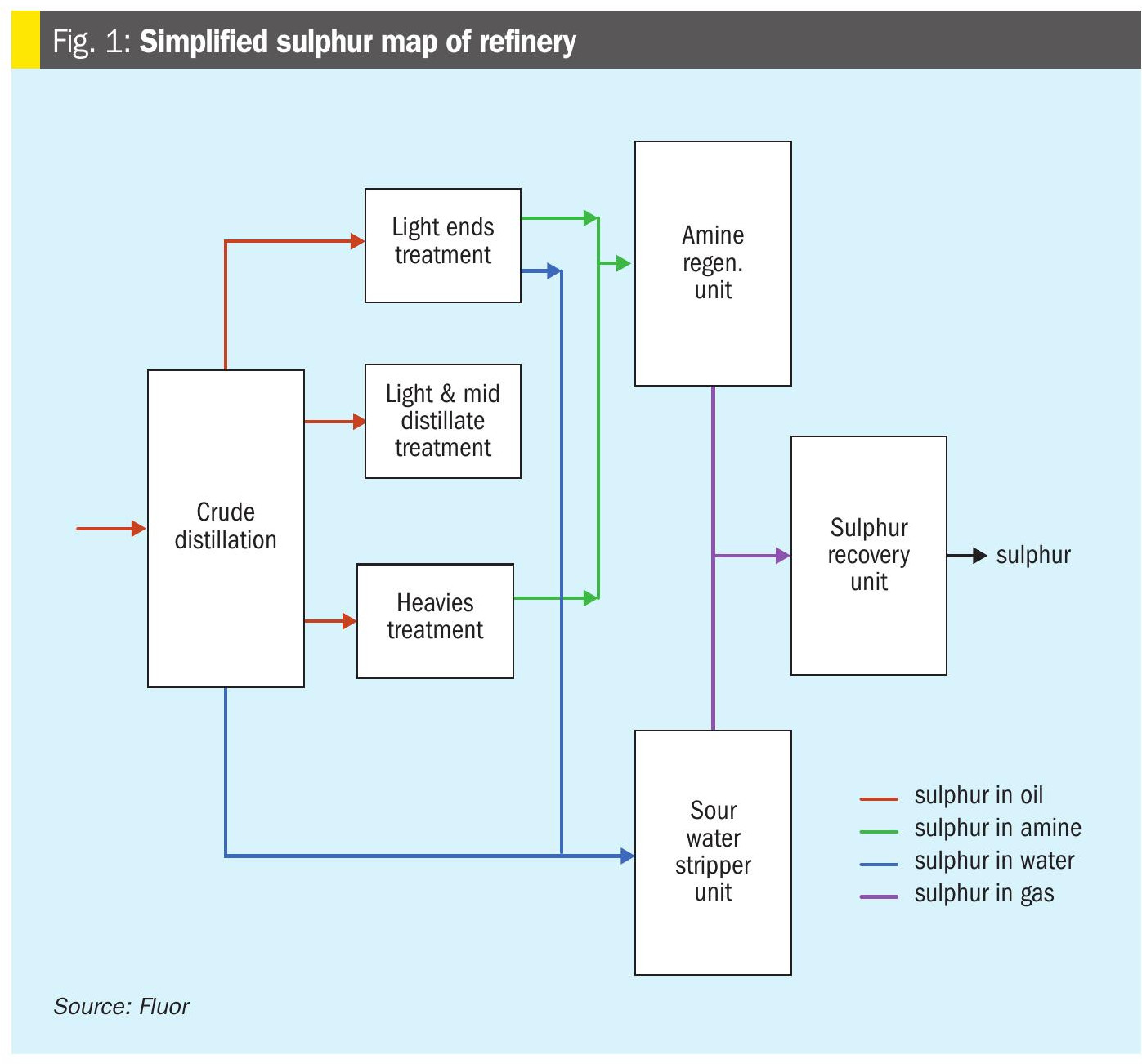

The sulphur compounds present in the crude get displaced from the hydrocarbon phase as H2S and that is either captured by an amine solvent in the amine treatment units or dissolved in the process condensate. The amine circulates in the refinery in a closed circuit, capturing the H2S from the hydrocarbon phase in various amine treaters. This “rich” amine (rich in H2S) is then regenerated in the amine regeneration unit (ARU) to liberate the H2S gas and regenerate lean amine (lean in H2S) to be circulated back to the various amine treaters. Similarly, the sour water generated from the various process units in the refinery is treated in the sour water stripping unit(s) (SWSU) to liberate the H2S and other gases. The combined stream of the H2S rich gases from ARU and SWSU is then sent to the sulphur recovery unit (SRU). Fig. 1 demonstrates how sulphur travels through the various process units in a refinery starting from the crude oil and ending with recovered elemental sulphur.

The H2S in the acid gas streams is converted to elemental sulphur utilising the modified Claus process. The typical feed gas streams to a sulphur recovery unit, originating from the amine regeneration and the sour water stripping units, contain varying amounts of H2S as the sulphur source. The process involves burning the acid feed gas with a sub-stoichiometric amount of air – typically, just enough to combust approximately a third of the H2S to SO2. The SO2 formed then reacts with the unconverted H2S to produce elemental sulphur.

The main reactions involved are:

Reaction 1 is highly exothermic, while reaction 2 is endothermic, with a net effect of exothermicity for the net conversion described by reaction 3.

Another reaction of importance and of special interest to this discussion is the destruction of ammonia in the presence of air.

The Claus reaction furnace needs to be hot enough to ensure a near complete destruction of ammonia to nitrogen with the target typically 1,260°C (2,300°F) for a standard Claus.

Traditional sulphur plants employing the modified Claus process utilise air as the source of oxygen in the thermal reaction furnace. The major drawback of using air as the oxygen source is the large amount of nitrogen that comes along with the oxygen supply. The nitrogen from air adds to the hydraulic load of the unit, thus “eating up” capacity. The nitrogen also adds thermal inertia, lowering furnace temperatures and increasing the duties of sulphur condensers and reheaters.

Oxygen enrichment has been implemented in many sulphur plants to debottleneck the process and reclaim SRU capacity. Oxygen enrichment is the process where part or full amount of the oxygenate needed for the modified Claus reaction is replaced by pure oxygen. Conventionally, oxygen enrichment is classified as low level, mid-level, and high level; and corresponds to the amount of pure oxygen mixed into in the air-oxygen mixture sent to the furnace. Low level oxygen enrichment typically limits overall oxygen concentration to 28 vol-% O2 in the final mixture of air and oxygen, whereas high level oxygen enrichment is a concentration greater than 45 vol-% O2. The in-between concentration is categorised as mid-level enrichment.

In this discussion, two case studies are provided to illustrate the ability of high level oxygen enrichment to provide the solution for two distinct issues that existing SRUs will likely face in the future of refining.

Case study 1 – capacity enhancement

The first case study involves a sulphur plant consisting of three identical trains, designed to process refinery acid gas equivalent to a total of 450 t/d (3 x 150 t/d) of sulphur production. The existing sulphur recovery unit consisted of the following systems:

- three identical Claus sulphur recovery sections including the thermal and catalytic stages;

- a dedicated sulphur pit and ejector for each of the SRU trains;

- a common tail-gas incinerator for all three trains.

The refinery needed to increase its sulphur handling capability to meet the present and future crude operating trends as well as to increase the overall flexibility of operation of the refinery. The owner proceeded to implement Fluor’s COPE® II high level oxygen enrichment to increase the sulphur handling capability by 50%. Utilising COPE® II high level oxygen enrichment technology would increase the amount of acid gas equivalent each of the Claus trains can process to 225 t/d of sulphur production while maintaining the same sulphur recovery efficiency. Oxygen enrichment reduces the volumetric flow of process gas and tail gas by reducing the quantity of nitrogen that enters with the combustion air. This reduction in volumetric flow rate allows for a corresponding increase in SRU acid gas feed rate and subsequent increase in sulphur production with the same main equipment in the SRU downstream of the Claus furnace.

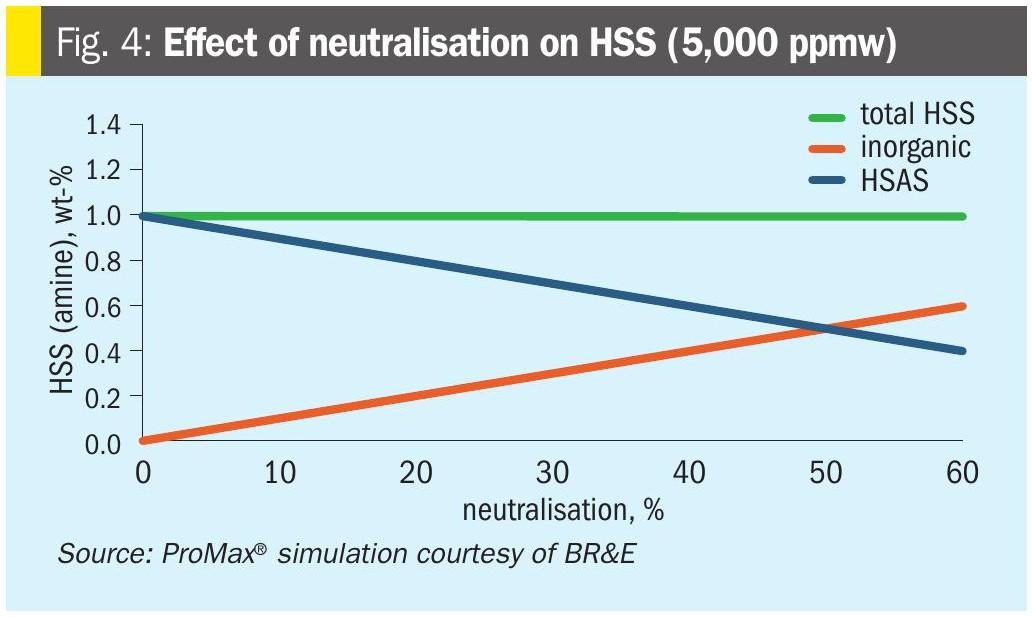

The typical composition of the feed gases to the Claus section for the sulphur plant is summarised in Table 1.

The feed gas composition is the same for the both the base case (air only operation) and the revamp case (oxygen enrichment) operations – the only differential between the two cases for the feed gas is quantity.

Table 2 provides a short summary of the flowrates for the various streams marked in the simplified flow diagram shown in Fig. 1 for the two operating cases as defined below:

- Base case – air only operation

- Revamp case – oxygen enrichment

As the table above clearly shows, when the unit operates with oxygen enrichment and processing 150% of the base plant capacity, the process gas flow from the first sulphur condenser is still less than the base case. Hence, there is no impact on the hydraulic load of the unit downstream of the first sulphur condenser even while it processes more acid gas.

The primary drawback of implementing high level oxygen enrichment is that with so little nitrogen diluent in the furnace, the bulk gas temperature achieved via combustion exceeds the allowable limits for any available refractory. Hence special design modifications are needed to provide adequate temperature control in the furnace.

Typically, the major equipment that is replaced/new in the revamp of an existing SRU is the COPE® II ejector, COPE® II burner, amine acid gas preheater (if existing is insufficient), and first sulphur condenser. For this specific revamp, additional updates were required to the existing equipment and piping to accommodate the increased sulphur production capacity.

The specially designed COPE® burner allows for the safe and effective processing of separate feed streams: air, high purity oxygen, acid gases, startup fuel gas, and, when necessary, recycle gas.

The COPE® II ejector is a key component in the system to moderate the furnace temperature. It sends a recycle stream back to the reaction furnace so that, as more high-purity oxygen is added,the operating temperature does not rise above the design limit of the furnace refractory. The recycle gas is taken from the outlet of the first sulphur condenser. The flow of recycle gas is controlled to maintain the desired temperature in the reaction furnace.

The following section provides a detailed description of the process and the design modifications implemented in the existing unit. The associated design for this case study has been defined in Fig. 2. This shows the simplified sketch of the front-end section of the SRU through the first sulphur condenser. The items highlighted in red lines are the equipment or equipment sections that are part of the revamp (addition of new equipment and replacement or modification of existing equipment).

COPE® II operation

The amine acid feed gas (AAG) and sour water acid gas first passes through respective, existing knock out drums to remove entrained liquid droplets before mixing. These gases are water saturated and when mixed, create the potential for condensation and salt formation. An amine acid gas preheater is added in the design before the mixing point to preheat the AAG to achieve an outlet temperature of 180°C, using MP steam supplied from the Claus waste heat boiler, avoiding condensation in the mixed stream and preventing potential condensation of elemental sulphur when the COPE® II recycle gas mixes with the feed acid gas. After mixing, the three combined gas streams are fed to the new, high intensity COPE® II main burner.

The main burner ensures high intensity mixing, sufficiently high combustion temperature and adequate residence time. The total O2 required for combustion is supplied by the combination of pure oxygen and air from the combustion air blower. For this design, the normal oxygen enrichment level at design sulphur capacity is about 55%.

COPE® II operation allows for higher levels of oxygen enrichment without exceeding the temperature limits of the standard refractory linings by recycling process gas from the outlet of the first sulphur condenser to the COPE® burner. The recycle gas flow rate is controlled to moderate the reaction furnace operating temperature. The expected temperature achieved in the reaction furnace is about 1,450°C during oxygen enrichment operation in this design.

The recycle gas is routed to the burner, using a new steam driven COPE® ejector. The recycle gas in COPE® II operation is relatively cool and mostly inert. The recycle gas acts as a heat sink that absorbs the required amount of the combustion heat release to maintain the reaction furnace temperature to within design limits during oxygen-enriched operations. The COPE® ejector motive steam is taken from the steam produced by the WHB downstream of the superheat coil.

The balance of the first sulphur condenser outlet gas is processed normally through the catalytic portion of the SRU train in similar fashion as in the existing SRU train. No further modification of the existing design is needed typically in the rest of the unit.

A new first sulphur condenser is required in this case to provide the necessary duty for processing 225 t/d of sulphur capacity, as well as to manage the higher flowrate of the process gas that now includes the COPE® II recycle gas.

Additionally, a few modifications in the existing waste heat boiler are needed. The expected outlet temperature during oxygen enrichment is higher than the original outlet design temperature. The proposed modification is to add a new layer of castable refractory in the waste heat boiler outlet channel, while the piping from the WHB to the first sulphur condenser is replaced with stainless steel piping.

Condensed sulphur from all sulphur condensers gravity drains through the existing sulphur seal pots and to the sulphur pit. A new pit vent ejector, which sends the vent gases from sulphur pit to the existing incinerator is needed. The new ejector will be designed for the new unit design rate of elemental sulphur and higher amounts of devolving gases.

Summary

For high levels of oxygen enrichment, the COPE® II process offers several advantages. The key features of the process include:

- proven technology with demonstrated operation of high level of oxygen enrichment;

- simple process equipment layout and straightforward process control;

- high level of reliability and flexibility.

The COPE® II process provides the benefit of on-line recycling for normal high-level oxygen-enrichment operation, but also for irregular operations such as start-ups, shutdowns, and feed disturbance rejection.

Case study 2 – processing lean gas

The second case study looks at a sulphur recovery unit which needed to process appreciable amounts of lean acid gas post a refinery upgrade project. The SRU is a traditional unit designed for the typical amine acid gas and the sour water stripper acid gas from upstream ARU and SWS unit. The unit has a capacity of 150 t/d of elemental sulphur production.

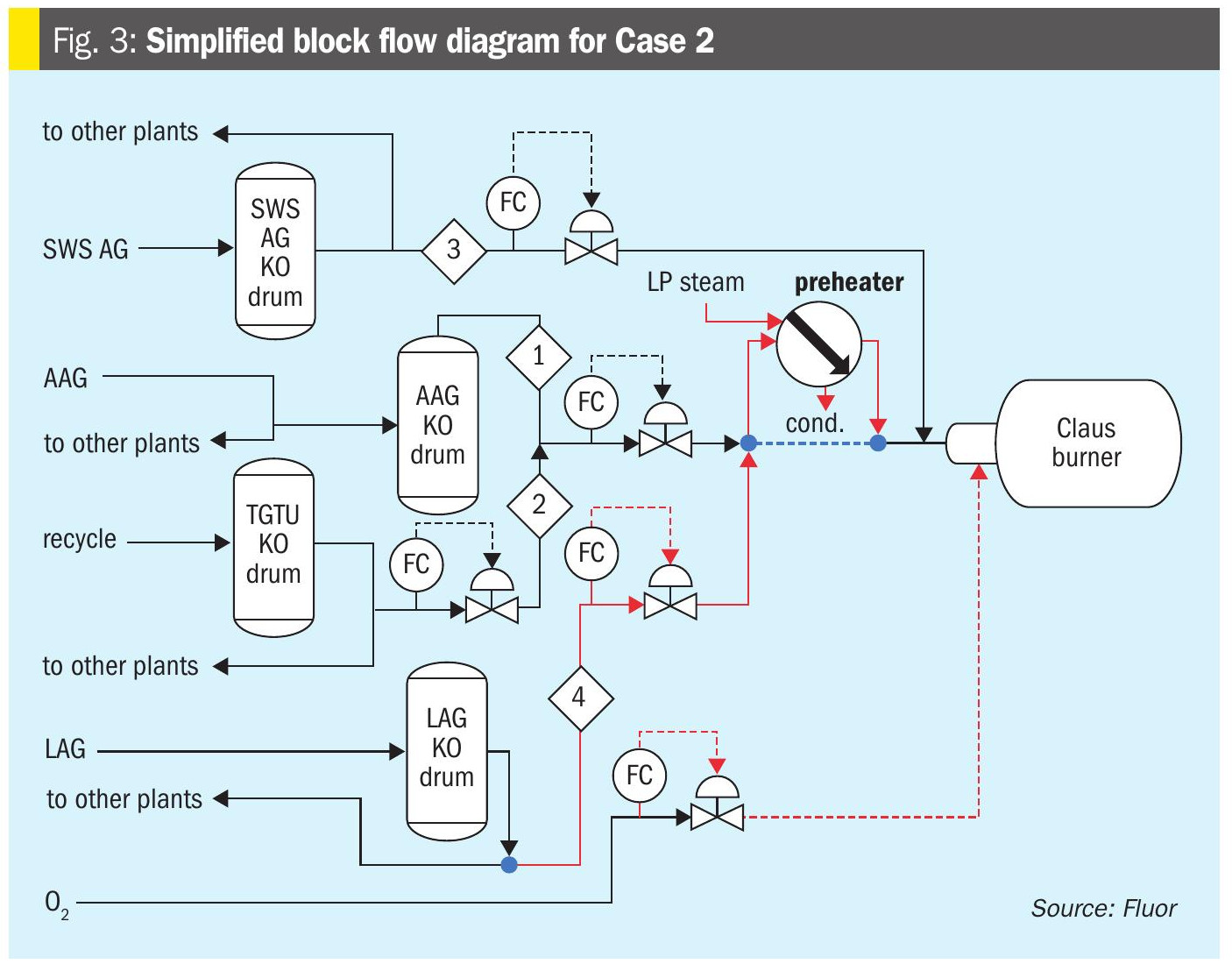

The refinery has multiple Claus units, each with a different capacity and design. All of the individual Claus sections were designed to operate with a common tail gas treatment unit (TGTU) with the TGTU recycle gas shared across all of the Claus plants. The feed gas streams were also shared between the multiple Claus plants. Post the refinery upgrade project, a stream of lean sour gas also will be processed in the existing sulphur block. A single Claus unit was chosen to process this additional new lean acid gas (LAG) stream. The following simplified block diagram (Fig. 3) presents the configuration of the unit whereby the new feed steam of LAG is introduced in the unit.

Like before, the items marked red are the new equipment or installations implemented as part of the revamp.

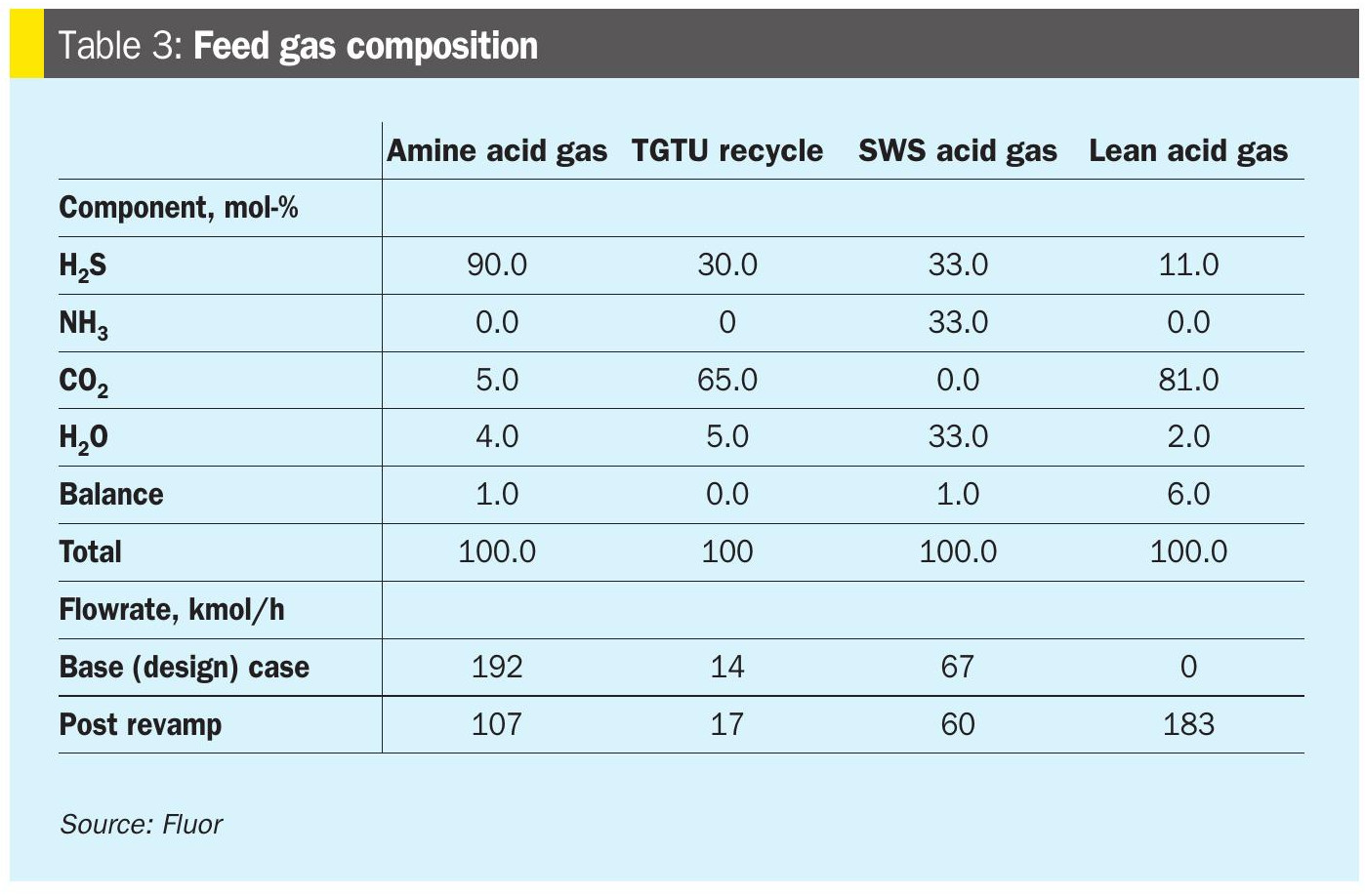

Table 3 lists the feed gas flowrates and compositions for the pre and post revamp conditions.

The base case data for 150 t/d sulphur production corresponds to conditions for which the unit had been designed for, while for the revamp case with the lean gas the sulphur load in the unit reduced to 110 t/d.

The major impact of processing lean feed gas in the existing Claus furnace is that it reduces the reaction temperature due to the presence of CO2 in the LAG. In this case, since the amount of lean acid gas is considerable, thus leading to high amounts of CO2 in the combined feed stream. Hence, the equilibrium Claus furnace is very low. The furnace temperature is expected to be around 1,000°C when the mixture of AAG, SWS, and LAG is processed in the existing unit.

Since the amount of elemental sulphur generated in the unit stays well below the design capacity of the unit, there is no need for any modification to the sulphur handling section, and the only design modification the unit demands is in processing the lean gas.

Design options

To manage the lean feed into the unit, design modifications in the sulphur unit are needed so that furnace temperature is maintained at an optimum value, above 1260°C for this operation. To increase the rection temperature, the following design options were considered.

Feed preheat

Feed preheat includes heating up the acid gas streams and/or the air stream supplied to the Claus furnace. Typically, LP steam is used as a heating medium, but under more unique cases, HP steam (typically the 40 to 45 barg steam raised from the waste heat boilers in Claus and Incinerator) can also be used. The steam level used defines the extent to which the streams can be preheated – with LP steam it is limited to 120 to 130°C, while with 45 barg steam, preheating up to 230°C can be achieved.

Unfortunately, even using 45 barg steam to preheat both the acid gas and the air streams, the furnace temperature is only 1,100°C. Further preheating implementing electric heaters has not been considering for economic reasons.

Co-firing

Another method of increasing the furnace temperature is to implement co-firing of fuel gas on a continuous basis. The combustion of the hydrocarbons helps increase the furnace temperature to acceptable limits.

For this unit, to achieve a temperature of 1,260°C in the furnace, around 800 kg/h of fuel gas co-firing is required. The available fuel gas is a stream of hydrogen rich gas, having the following typical composition as shown in Table 4.

A major drawback of using co-firing on a permanent basis is that it increases the potential for coke formation and hence rapid deactivation of the downstream Claus catalysts and also increases the process gas and tail gas flowrates beyond the design capacity of the unit – the tail gas flow is more than 130% of the base case design value. Thus, implementing co-firing would require a much larger revamp than just adding the co-firing. For these reasons this option was not implemented.

Oxygen enrichment

Oxygen enrichment would allow for the ability to elevate the furnace operating temperature by way of removing diluent gases. To achieve the required furnace temperature, the optimal oxygen enrichment level was found to be 60%. To achieve the correct combustion and reaction environment with high level oxygen enrichment, a new high intensity burner would be needed.

The option of oxygen enrichment became the chosen option for the client. The client also elected to replace the reaction furnace. The replacement of the furnace was not a mandatory change, but was included as part of the project only because the existing furnace is old and prone to a number of age-related issues.

The acid gas preheater using LP steam is also included in the design because the LAG is colder than ambient temperature, and preheating the stream has a positive impact in optimising oxygen usage.

Table 5 summarises the operating conditions for the unit, post revamp.

Since, the refinery has oxygen available in situ, not depending on outside suppliers or new installations for the post revamp high level oxygen enrichment operations made this the most viable option.

A major advantage of the revamp to process the LAG using high level oxygen enrichment is the fact that even when the feed gas flow of the unit increased due to the increased flow of the LAG, usage of high level oxygen enrichment reduces the overall flow of process gas and tail gas in the unit. The unit remained hydraulically capable of processing the feed gas mixture with no major modifications beyond the Claus furnace, the tail gas flow for the revamp operation is actually less than 70% of the base case. Thus, all equipment downstream the Claus furnace continued to operate at less than design capacity.

The revamp also meant that the unit remained capable of handling the original feed gas composition if needed along with any variation from mixing the rich amine acid gas and the lean acid gas streams. The oxygen enrichment level can be easily fine-tuned based on the expected feed gas compositions, thus allowing this unit to process a wide range of feed gas compositions.

Summary

Implementing the high-level oxygen enrichment in this project allowed the unit to operate with the revised feed gas composition. Implementing high level oxygen enrichment had the following advantages:

- Minimum revamp needed – existing equipment (burner and furnace) replaced in situ, new exchanger added in available space, no new plot area required.

- Operational flexibility – unit able to operate over a wide range of feed gas compositions by managing the level of oxygen enrichment.

- No impact to the unit beyond the existing Claus furnace – operating sulphur handling capacity post revamp well below design values.

Conclusions

In conclusion, sulphur recovery units across the globe may need to upgrade to meet new demands for the future. The most common requirement is to process higher sulphur loads as refineries across the globe are processing crudes with higher sulphur content and are also implementing residue conversion projects. Other adaptations are frequently required for processing more challenging feed ‘cocktails’ which may be encountered as there may be the requirement to process lean acid gas streams. Oxygen enrichment proves to be a very successful engine to manage multiple requirements in SRUs, both for capacity enhancements as well as to deal with very changing acid gas streams as the case study data proves. These revamp options provide more efficient and economically viable options instead of adding new plants to cater to the new needs.