Sulphur 420 Sep-Oct 2025

15 September 2025

Best practices in SRU steam and condensate handling

SRU THERMAL MANAGEMENT

Best practices in SRU steam and condensate handling

Miles Andrews of QMax Industries explains why effective steam and condensate management is essential to the performance, safety, and reliability of sulphur recovery units, covering how steam is generated and used across key equipment, the importance of steam quality, and the risks of condensate such as water hammer and corrosion.

Steam and condensate handling is a critical part of the sulphur recovery unit (SRU). While attention often centres on Claus reaction kinetics and catalyst performance, thermal management via steam systems ensures the entire process remains stable, efficient, and safe. Poorly managed condensate in a SRU steam system can cause corrosion, water hammer, and process disruptions. In high SO2 and H2S environments, poor temperature control can lead to expensive fouling and maintenance problems. This article provides a comprehensive overview of how to handle steam and condensate in SRUs, from tracing and jacketing to the critical roles played by traps and design best practices.

Steam considerations

Steam is used across an SRU for heating process gas, preventing sulphur solidification, and enabling phase change operations. From maintaining reheat temperatures between catalytic reactors to keeping run-down lines above the sulphur freezing point, steam provides the thermal energy needed to ensure stable and efficient operation.

Steam quality is critical. Dry, saturated steam delivers consistent heat, while wet steam (laden with condensate) reduces thermal efficiency and increases the risk of water hammer. This dangerous phenomenon, caused by slugs of condensate moving at high velocity, can damage piping, valves, and traps. It is mitigated through proper trap placement, sloped lines, and the use of steam separators.

Condensate also poses a corrosion risk. When left to stagnate, it can absorb CO2 and form carbonic acid, which accelerates the degradation of carbon steel. Sloping tracer lines, adding drains, and using corrosion-resistant alloys in critical areas are key strategies to reduce this risk and maintain system integrity.

Steam traps

Steam traps are devices that remove condensate from steam systems while keeping steam in. A well-chosen and properly installed trap is essential to thermal efficiency and system longevity.

There are three main classes of steam traps:

Temperature actuated mechanisms:

- Thermostatic traps use a fluid-filled bellow or capsule that expands when steam is present and contracts in the presence of cooler condensate. These are best suited for tracing systems and startup venting.

- Bimetallic traps use two metals with differing expansion rates to actuate the trap. They are durable and well-suited to high-pressure systems but may have slower response times.

Velocity/temperature actuated mechanisms:

- Thermodynamic traps operate using the difference in velocity and pressure between steam and condensate. When condensate enters the trap, it is discharged. When steam arrives, it creates a pressure imbalance that forces the disc down, closing the trap.

- Disc traps, a subtype of thermodynamic traps, are rugged, compact, and ideal for outdoor or remote installations.

- Inverted bucket traps use a buoyant bucket that floats when filled with steam and sinks when filled with condensate, opening a discharge valve. These are most commonly used with steam tracing systems.

- Float and thermostatic (F&T) traps combine a float for continuous condensate drainage and a thermostatic element for air venting. These are ideal for broad loads like heat exchangers.

Proper trap selection depends on system pressure, condensate load, reliability needs, and installation space. An incorrectly sized or misapplied trap can cause steam loss, condensate buildup, or freeze risk.

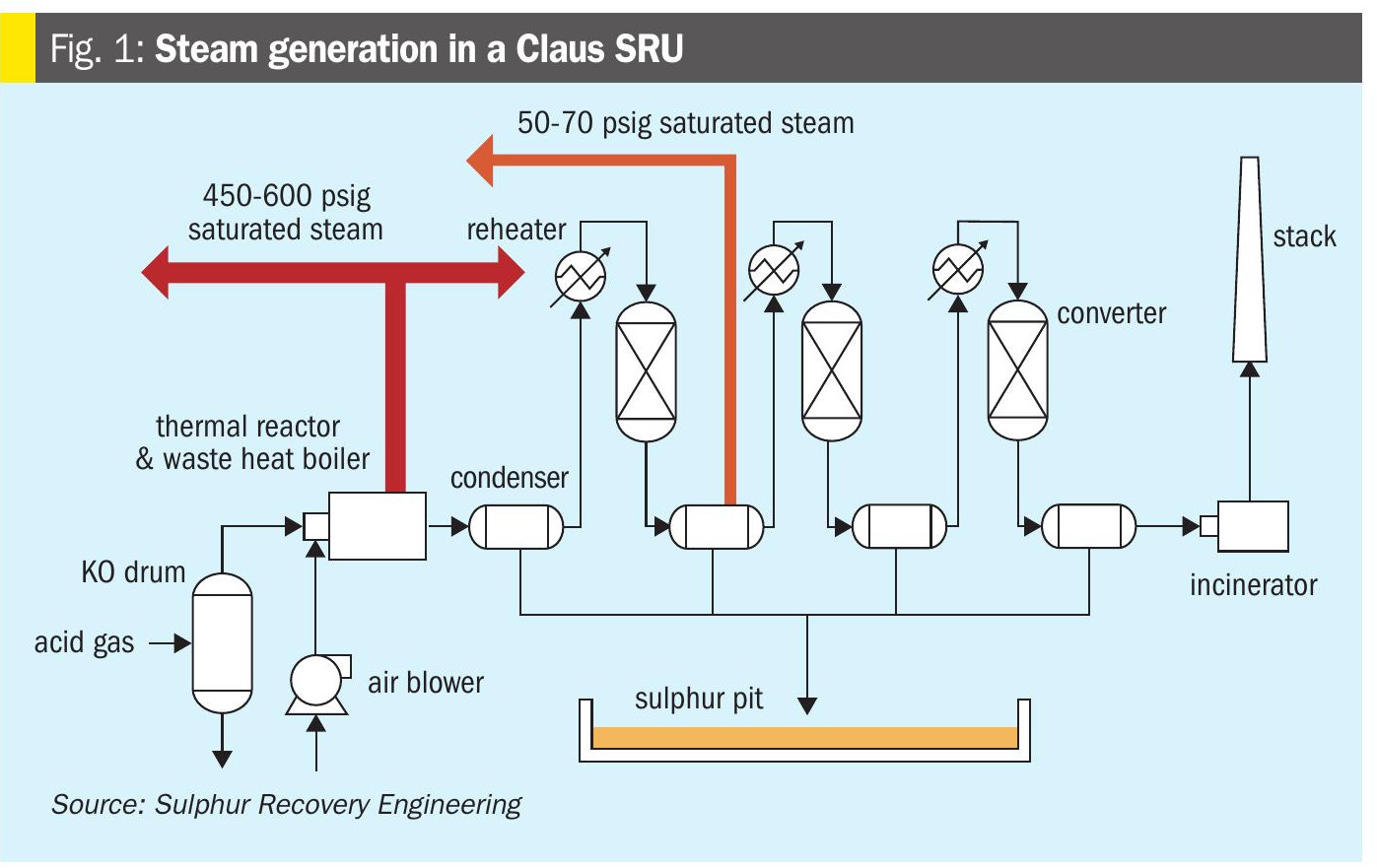

Equipment that generates steam in SRUs

The two main outputs of a Claus SRU are steam and sulphur, with the steam produced being substantially more valuable to a refinery than the sulphur recovered. Most of the steam produced is exported to other units within the refinery, and it is generated by a few key pieces of equipment within the SRU.

Waste heat boiler (WHB): Located immediately downstream of the thermal reactor, the WHB recovers intense thermal energy from the high-temperature Claus gas stream (typically over 2,000°F or 1,100°C). This energy is used to generate high-pressure steam, which can be exported or used internally. Proper operation of the WHB ensures energy efficiency and protects downstream equipment from thermal overload.

Sulphur condensers: Primary and secondary condensers condense elemental sulphur from the process gas stream. The heat removed in this process is used to generate medium- or low-pressure steam. These units are critical to maintaining the mass balance of the SRU and enabling downstream catalytic reactions.

Proper thermal integration of these steam-producing units ensures that heat energy from the exothermic Claus reactions is not wasted.

Equipment that uses steam in SRUs

Steam plays a vital role across SRU equipment, both for process heating and freeze protection.

Process gas reheaters (PGRs): Reheaters elevate the process gas temperature between catalytic converters to maintain optimal reaction conditions. This is typically done using shell-and-tube exchangers with high-pressure steam. Undershooting target temperatures reduces sulphur yield, while overshooting can damage catalysts.

Combustion air pre-heaters: Pre-heating combustion air entering the thermal reactor improves combustion efficiency and flame stability and increases the reactor’s ability to destroy volatile compounds. These may use steam coils or indirect exchangers and are essential in cold climates or during startup.

Acid gas strippers and knockout drums: These vessels must be thermally protected, especially in the liquid phase regions, to prevent freezing or hydrate formation. Steam tracing or jacketing is used around nozzles, drain lines, and liquid outlets.

Sulphur run down lines: These lines transfer molten sulphur from condensers to the sulphur pit. If the temperature drops below the freezing point of sulphur, solidification occurs, blocking the line. Tracing or jacketing is a must, with redundancy in many designs to ensure continuous operation.

Sulphur seals and collection pits: Seals prevent backflow of gases, and both the seal leg and pit require steam jacketing or tracing. In some cases, the pit includes submerged coils or external panels for heat maintenance.

Tail gas lines and analysers: Tail gas lines must remain above dew point to avoid condensation and fouling of analyser probes. Steam tracing and insulation ensure the tail gas reaches the tail gas treating unit (TGTU) and analytical instruments safely.

Thermal maintenance

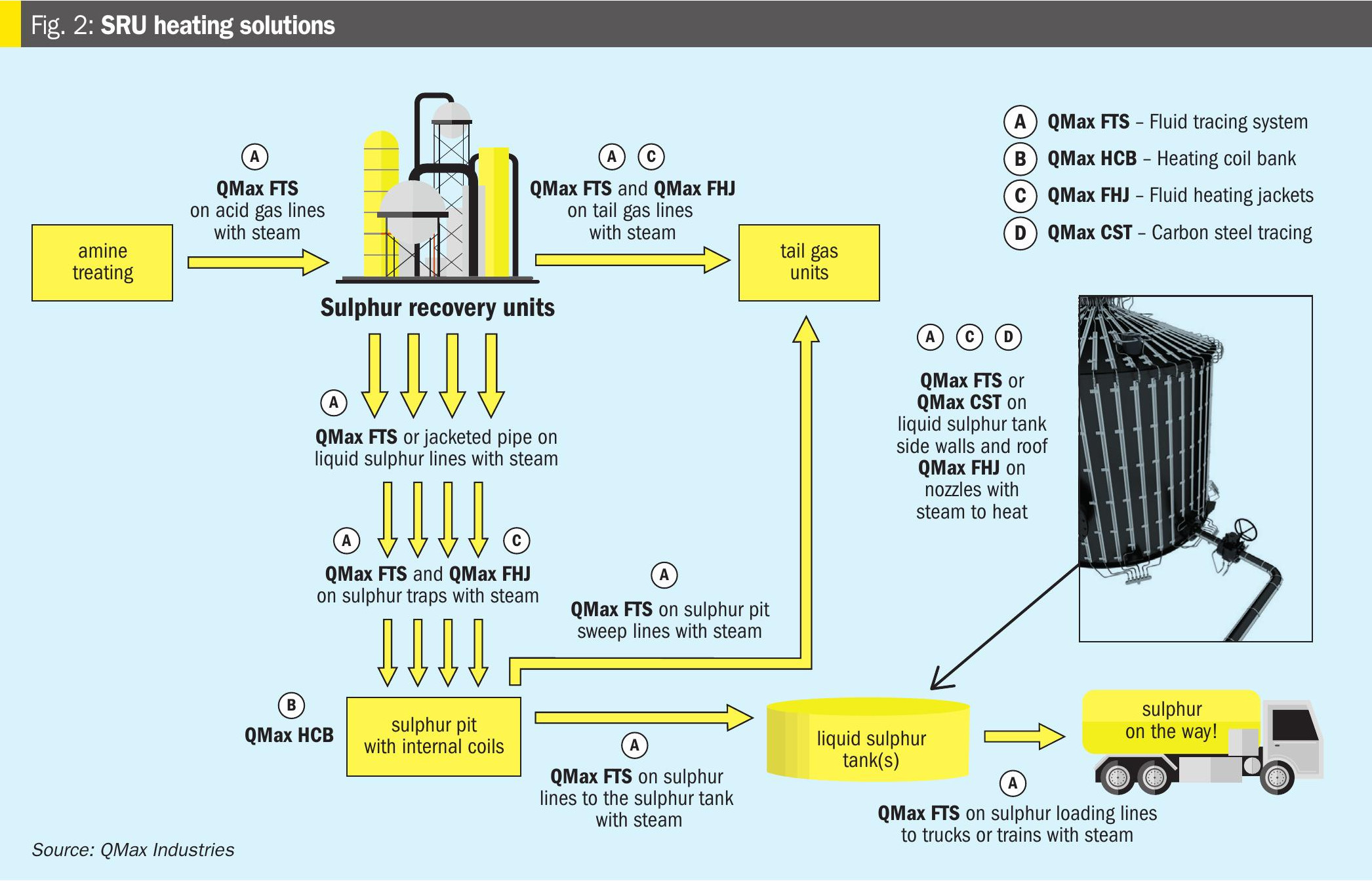

Several types of thermal maintenance strategies are deployed in SRUs:

Jacketed pipe: Commonly used for high-viscosity or high-solidification-point fluids like sulphur. Jacketed pipes use a secondary pipe (the jacket) around the process pipe, with steam flowing through the annular space. It provides uniform heating with high steam condensing rates and maximum heat transfer, but it is often more expensive and complex to install.

Cross-contamination can be a common issue when unintended mixing of the process and heating medium occur. Leaks are commonly caused by manufacturing defects, corrosion, or stress from thermal expansion between the core pipe and surrounding jacket.

Steam tracing: Cost-effective and flexible products such as QMax FTS (Fluid Tracing System) and QMax CST (Carbon Steel Tracing) are often used for heating liquid sulphur and vapour lines.

QMax FTS is a type of tube tracing that involves installing tubing (usually ½-inch outside diameter), carrying steam along the process pipe with a conductive aluminium tracer. The aluminium transforms the nature of steam tracing from ineffective convective heat transfer to highly efficient conductive heat transfer. It is flexible, relatively easy to install, and delivers high performance for critical tracing applications like sulphur lines.

QMax CST is a 1-inch x 2.25-inch rectangular boiler tube that is custom-fabricated and contoured on one side to match the outside diameter of the process pipe. QMax CST is specifically designed for long-run hot oil tracing but can be used with steam in many applications as well.

For both systems, the quantity of tracers is determined by thermal calculations and the required heat duty.

Electric tracing: Used when steam is unavailable. Electric heat trace cables must be rated for hazardous areas and matched to system heat loss. Because the watt densities needed require the use of MI (mineral insulated) cable, and an entire tracing circuit is usually controlled by only one or two feedback points, electric tracing systems pose risks of both under- and over-heating in sulphur applications.

Equipment jacketing: Ensures uniform heating of valves, pumps, drums, filters, and vessels. Fluid heating jackets such as the QMax FHJ are often used in SRUs to maintain process temperature in various types of equipment. Each jacket is designed specifically for each piece of process equipment, creating a “heat shield” around the component.

Tank heating: Often heated through internal steam coils or external tracing. Design must ensure even heat distribution and avoid underheating/overheating localised zones. Careful consideration should be taken to prevent sulphur vapours from corroding tank walls.

Best practices include proper insulation selection (calcium silicate or mineral wool, for example), labelling of traced lines, and designing tracer circuits with proper lengths and elevation rises to avoid pressure drop or condensate build-up.

Installation considerations

When installing thermal systems in an SRU, precision matters:

- Steam lines should be sloped to encourage proper condensate drainage.

- Trap stations must be accessible for maintenance and testing.

- Steam tracers should allow for thermal expansion as the system heats up and expands.

- Bolt-on jacketing systems must be properly insulated to avoid heat loss.

- Bolt-on steam tracers should be tightly installed to ensure proper conduction from the tracer to the process pipe.

Poor installation leads to cold spots, corrosion under insulation, and excessive steam consumption.

Design considerations

Designing an effective tracing or jacketing system involves:

- Determining how much energy is needed to maintain minimum temperatures in worst-case ambient conditions.

- Choosing the correct steam pressure and temperature based on heat transfer needs and line length.

- Selecting proper insulation thickness and type, accounting for wind, rain, and ambient temperature variation.

- Ensuring every traced line or jacket segment has appropriate condensate removal.

- Avoiding rises in elevation and ensuring proper steam circuit lengths per the heat loss calculations.

- Avoiding trap placement in high or confined spaces without safe access.

Design should also incorporate redundancy for mission-critical systems like sulphur rundown lines and sour water drain lines. This allows for process heating to continue if a steam trap fails.

Conclusion

Efficient steam and condensate handling is essential for high-performance sulphur recovery units. From process stability and safety to energy conservation and maintenance reduction, thermal systems play a major role in the entire SRU operation. Understanding steam generation and usage, proper trap selection, installation practices, and robust design can prevent downtime, protect assets, and improve overall plant economics.

As SRUs evolve to meet stricter environmental standards and maximise sulphur recovery, so too must their thermal systems. By investing in sound design and maintenance of steam and condensate infrastructure, operators can ensure a reliable, high-performing SRU well into the future.