Best practices in SRU steam and condensate handling

QMax Industries explains why effective steam and condensate management is essential to the performance, safety, and reliability of sulphur recovery units.

QMax Industries explains why effective steam and condensate management is essential to the performance, safety, and reliability of sulphur recovery units.

As well as a recent US Chemical Safety Board report on an ammonia release incident, the past year has seen considerable focus on safety of ammonia at sea, in preparation for its possible use as a clean burning maritime fuel.

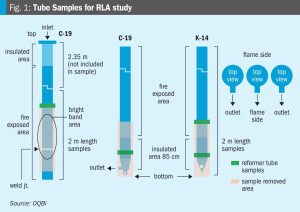

Muhammad Faisal Faraz and Abdullah Al Balushi of OQBi explain how by implementing a series of technical and process improvements, OQBi has successfully extended the lifespan of its reformer tubes by six years beyond the original design life of 100,000 hours.

Wood presents the pros and cons of leaving a refinery SRU on hot standby versus long-term idle taking into consideration reliability, safety, and operations responsibilities during extended downtime.

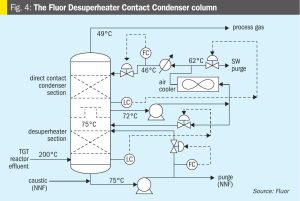

Fluor discusses the main causes, detection techniques, management methods and prevention procedures of SO2 breakthrough in the quench water system of a TGTU, with some unique design features for Fluor’s Desuperheater Contact Condenser.

Building on the success of its previous conferences, SulGas Mumbai 2025 brought together 154 sulphur and gas treating stakeholders, representing 68 companies for its 7th technical forum in the Indian subcontinent. We report on some of the key topics on the agenda.

In part 5 of this series on stripper efficiency issues we conclude the discussion with a focus on fouling inside stripper tubes.

Apart from having a good plant design, good maintenance practices and good operational discipline are key to optimise the performance of an acid plant and to protect it from corrosion and achieve a long life. B. Mumba, T. Mwanza and P. Ng’ambi of Kansanshi Mining PLC explore the Kansanshi sulphuric acid plant operations and the key parameters monitored and practices adopted that have helped to extend the catalyst campaigns from two years to four years.

Sulphur Experts Inc. combines new learnings, historical data, and recent onsite experience from operating companies to show what factors really impact ammonia plugging risk and what can be done to control them in order to allow for a wider operating range for SWS processing in the refinery SRU.

The world has seen a number of hydrogen explosions in double absorption plants mostly in the intermediate absorption tower (IAT). To review this increase and to determine the causes, an International Hydrogen Safety Workgroup was formed including major acid plant contractors, major acid producers, and consultants in the sulphuric acid arena. Davis & Associates Consulting explores some of the findings.