Nitrogen+Syngas 397 Sep-Oct 2025

12 September 2025

Optimising the finishing strategy for urea products

UREA FINISHING TECHNOLOGY

Optimising the finishing strategy for urea products

Stamicarbon has optimised urea granulation to meet rising global fertilizer demands by improving product robustness, reducing capital and operating costs through a simplified design, enhancing environmental performance with acidic scrubbing and UAS recycling, and scaling single-line plants up to 5,000 t/d while maintaining reliability and uptime.

As global agricultural production keeps growing to feed a rising population, expectations on urea producers are intensifying in parallel. Today’s nitrogen fertilizer industry operates in a highly interconnected, capacity-sensitive market, where fluctuations in production and logistics challenges increasingly influence operational strategy.

Producers are under pressure not only to deliver larger volumes but to ensure their product maintains its physical integrity throughout global distribution. The need for urea granules with higher crushing strength, low caking tendency, and lower dust formation has become essential, driven by the global nature of fertilizer trade. The ability of urea granules to withstand shipping and storage conditions is now a requirement for market access.

At the same time, sustained demand from key importing regions, combined with continued stress on global logistics infrastructure, is encouraging many producers to prioritise large, single-train urea projects. These high-capacity facilities depend on granulation systems that can deliver consistent performance, high uptime, and comply with increasingly stringent environmental standards.

Moreover, technologies that offer added flexibility and access to new applications can be transformational. For urea plant operators, solutions that enable diversification, such as the integration of diesel exhaust fluid (DEF) production, can unlock additional revenue streams and improve competitiveness in an increasingly challenging market.

This article explores how advancements in granulation technology, and its integration with complementary solutions, are enabling producers to respond to these evolving demands and position themselves for long-term resilience and growth.

The granulation process

Stamicarbon, the nitrogen technology licensor of NEXTCHEM, has extensive experience licensing urea granulation plants in various markets. Stamicarbon began developing its granulation technology through test facilities and smaller-scale units, before launching its first large-scale grass-roots plant in Egypt in 2006, which was later successfully revamped to operate at an even higher capacity.

Contracted in 2011, the Pardis III plant in Iran (Fig. 1) was the largest operational granulation facility based on the Stamicarbon granulation design at the time of its start-up in 2018, with a nameplate capacity of 3,250 t/d. The plant can operate at 110% capacity with a turndown ratio of 60% of the nameplate capacity. It is connected to a fertilizer-grade urea plant based on Stamicarbon’s pool condenser design. Despite challenging weather conditions, the plant proves the reliable performance of the design, achieving an on-stream time of more than two months during extreme heat in summer.

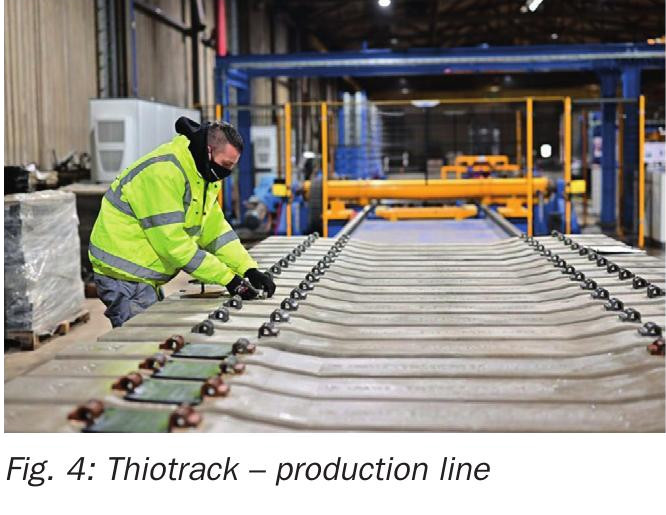

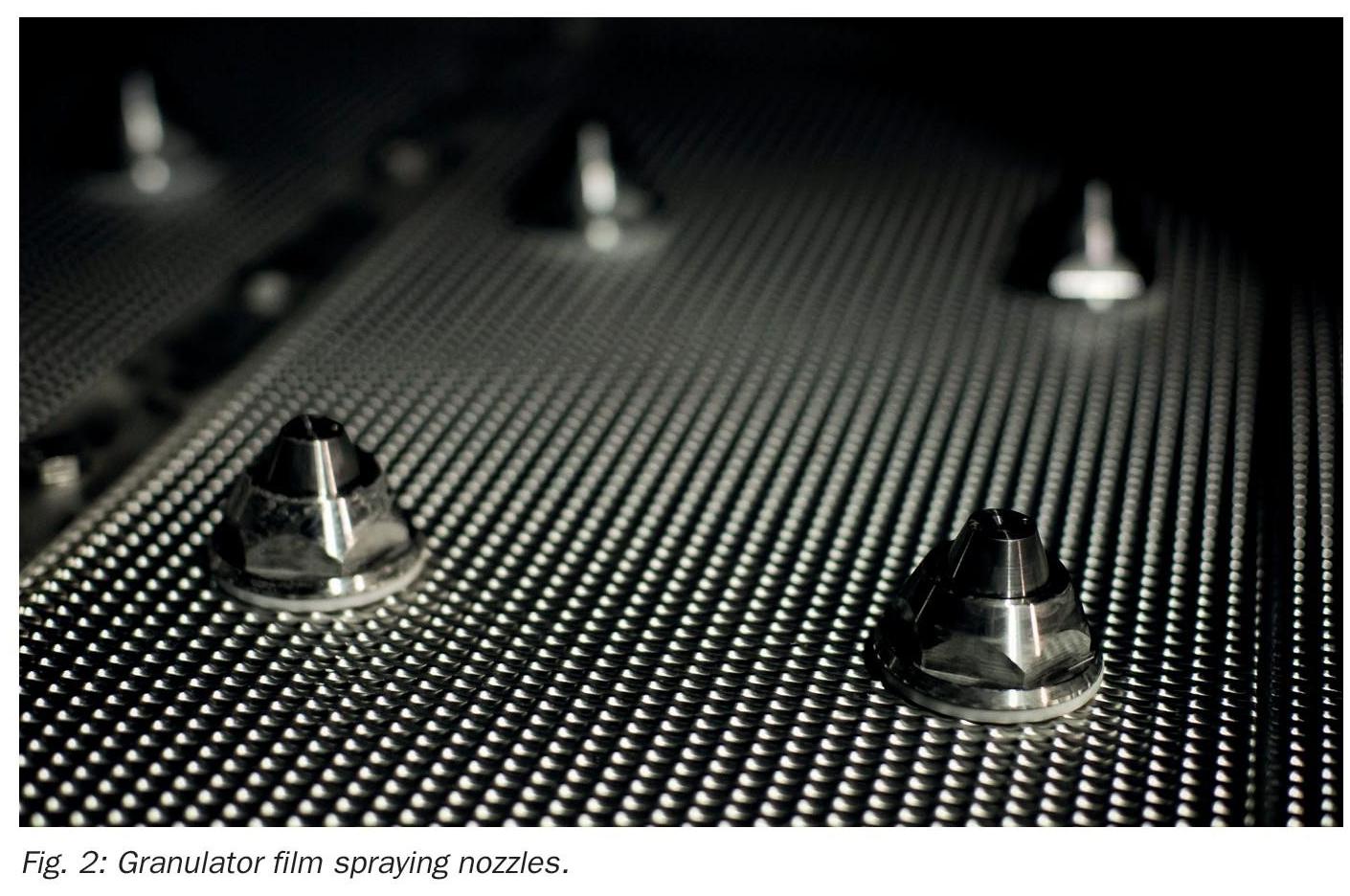

In the original Stamicarbon urea fluid bed granulation process, urea melt with a concentration of about 98.5 wt-% is distributed by film spraying nozzles of proprietary design (Fig. 2). Granule seeds are coated with thin layers of urea melt film until they reach the required product diameter. This process stands out as highly cost-effective in terms of operational costs due to reduced formaldehyde content in the final product and low dust formation. In practice, this design has proven to operate for up to three months straight without the need for cleaning.

Since the first implementation, nearly 20 plants of various capacities have been licensed, designed, and put into operation.

Further optimisation

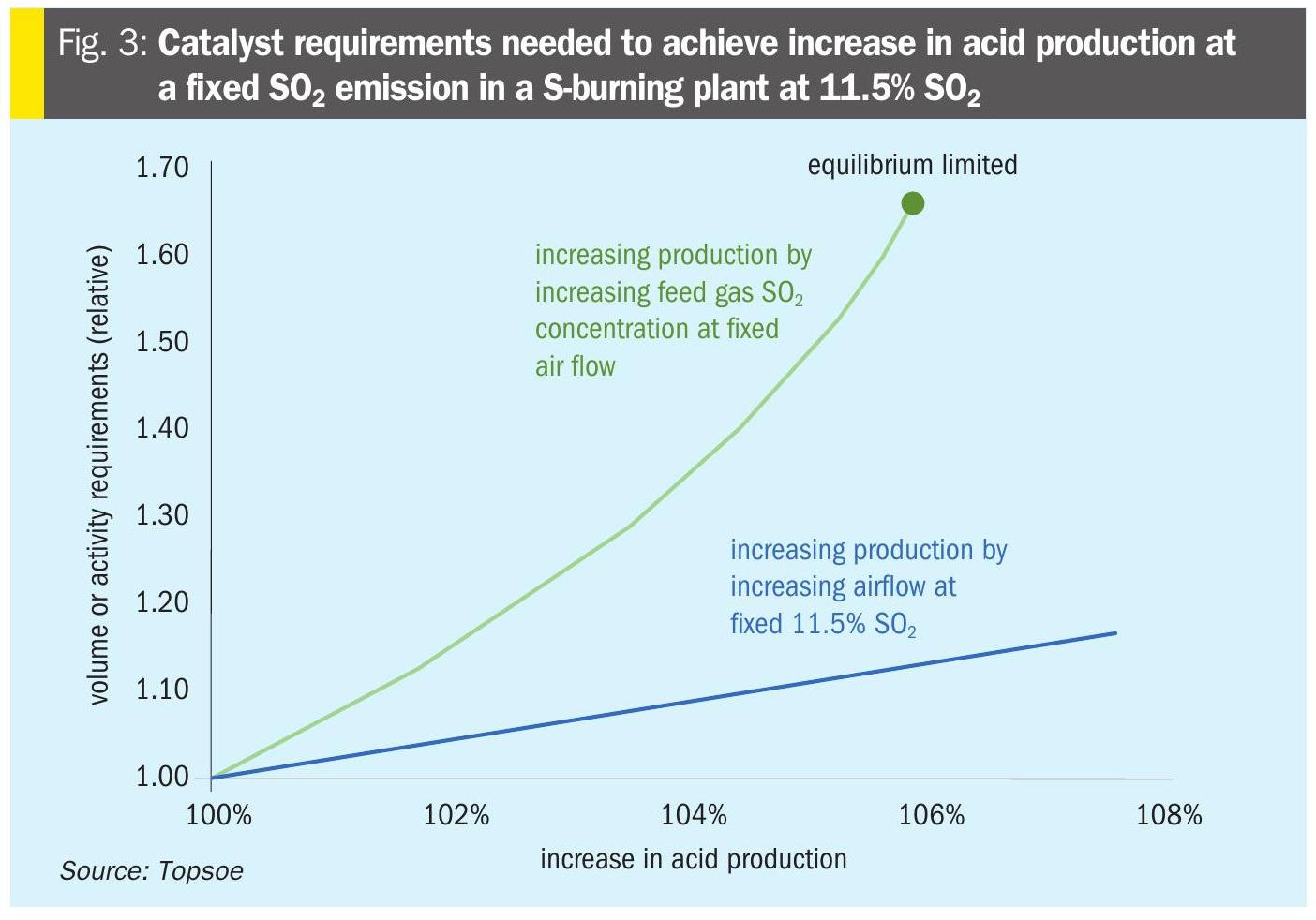

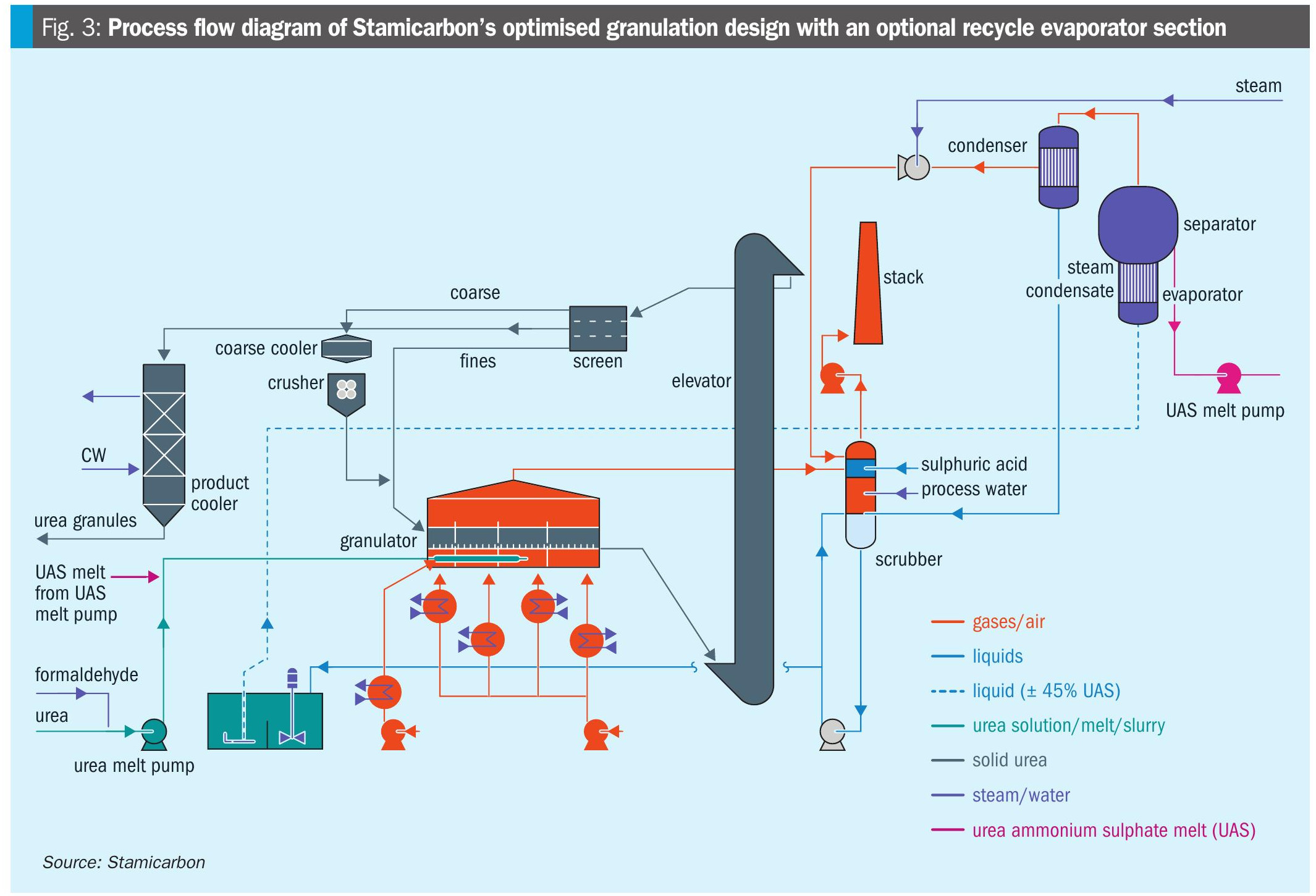

In 2008, Stamicarbon introduced its optimised granulation design. It is distinct for its simplified layout (Fig. 3) with fewer equipment items, enabling a significant reduction in capital expenditure and operational costs while keeping its original performance and high on-stream times. In this improved design, the urea melt is fed to the granulator the same way as in the standard Stamicarbon design. The key difference is in the last compartment, where the granulated product is cooled down to a lower temperature. After passing the lump screen, the product is directly lifted with a bucket elevator to the classification equipment. Further, the complete solid product flows, using gravity force, through the main screens. The coarse product is fed to the crusher after cooling to temperatures below 70°C. The crushed product and the fines recycle flow are combined and recycled into the first compartment of the granulator as so-called seeds. The on-specification end-product in the outlet of the main screens is cooled to a storage temperature in a solid flow cooler that makes use of cooling water instead of cooling air. The dust-loaded air from the granulator, coarse cooler, and all the de-dusting points are collected and fed to a single granulator scrubber.

Eliminating two main fluidisation fans leads to significant cost savings in power consumption. The fluid-bed granulator cooler was omitted by increasing the length of the cooling zone in the original granulator, and the fluid-bed product cooler was replaced by a solids flow cooler. Furthermore, the respective granulator cooler scrubber with all necessary pumps and a fan were also omitted.

A water injection system was installed in the discharge of the fluidisation air fan to decrease the amount of fluidisation cooling air. This water injection system produces very fine droplets that evaporate along the air path to the granulator, cooling the fluidisation air. This feature is particularly efficient on exceptionally hot days or when the plant operates at production rates above its nameplate capacity. During such times, higher amounts of fluidisation air are expected, and using this system can significantly reduce those amounts.

Reducing equipment items significantly decreased the granulation plant’s footprint and capital cost. The total capital expenditure reduction is not only achieved by eliminating equipment, but there are also savings in shipping cost, cost of insurance, construction, and the effect of reduced land use. Less operational equipment will also result in a reduction in maintenance costs and further operational savings.

Reducing emissions

During the crystallisation process of the urea melt in a granulator, the ammonia present in the urea melt is released and, in most cases, emitted into the air. Stamicarbon’s granulation process, designed for efficient and environmentally friendly production, incorporates acidic scrubbing for effective ammonia capture. After the dust scrubbing stage, sulphuric or nitric acid is injected into a circulating aqueous solution brought into contact with the ammonia-laden air. The acid reacts with ammonia, effectively reducing its concentration in the exhaust air. The ammonium salt generated in this reaction can be sent outside battery limits or, if sulphuric acid is applied, incorporated into the end product. In this way, no disposal streams are sent to the atmosphere.

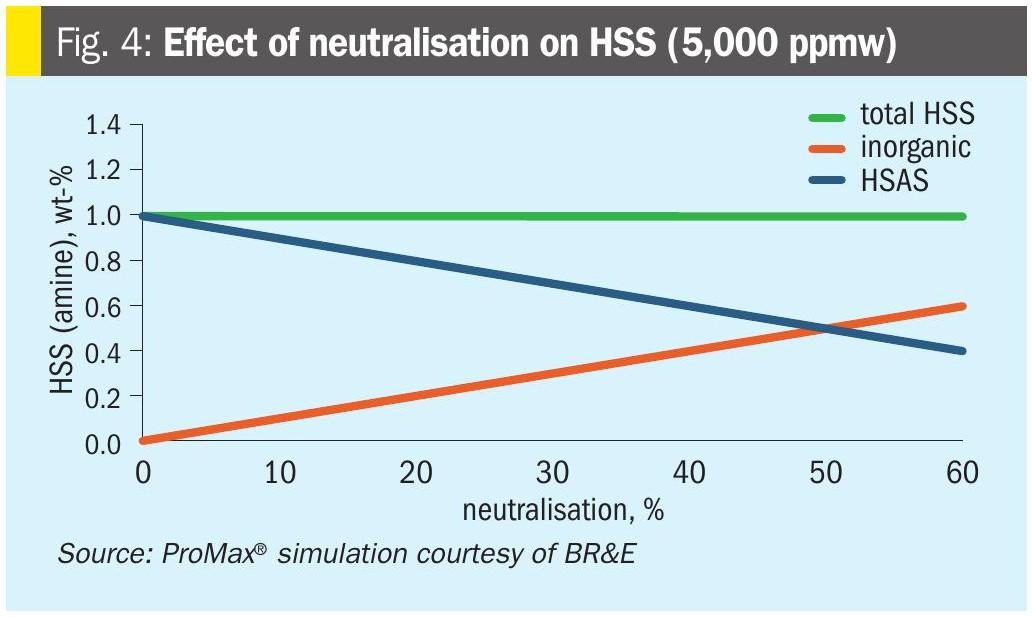

To develop this design, several obstacles needed to be addressed. The salt produced by the scrubbing system is about 55% water by weight and cannot be directly mixed with the main urea melt, which only contains 1.5% water and is fed into the granulator through nozzles. Therefore, to manage the water content in the recycled liquid urea ammonium sulphate (UAS) sent back to the granulator, a specific evaporation process is required (as illustrated in Fig. 3). This recycled UAS solution is then combined with the urea melt inside the granulator. The sulphur content in the end product is minimal, roughly 0.05-0.1% S, allowing the granules to be marketed as standard urea.

In response to increasing demand for sulphur as an essential plant nutrient, Stamicarbon has developed an innovative and adaptable modular process for manufacturing granulated urea enriched with higher levels of ammonium sulphate. A common approach involves recycling and concentrating liquid urea ammonium sulphate (UAS), allowing the salt to exit the granulation plant in solid form after being combined with molten urea. In Stamicarbon’s design, solid ammonium sulphate is added to molten urea. Existing granulation plants can be retrofitted to use this innovative design with some modifications, installation of additional equipment, and potential upgrades to construction materials.

Scaling up to 5,000 t/d

Recent decades have seen a rapid rise in projects featuring higher plant capacity. Urea granulation plants with capacities over 3,000 t/d have proved to meet the growing performance and on-stream requirements.

Stamicarbon explored designing larger-capacity plants while maintaining its proven design philosophy and product quality. This led to the conclusion that a single-line configuration is more advantageous than a double-line configuration (two lines of 2,500 t/d each), as it could offer approximately 30% in capex savings on total investments.

In 2019, Stamicarbon licensed its first single-line 4,000 t/d urea granulation plant. The plant is equipped with the MMV scrubber to comply with environmental regulations. In 2022 and 2023, Stamicarbon secured contracts for licensing two more plants with a capacity of 4,000 t/d each for a customer in Africa.

Based on the experience with scaling up the conventional design, certain operational and manufactural challenges and supporting measures have been solved to scale up the optimised granulation design, making it possible to design a single-line 5,000 t/d granulation plant.

Diversifying product portfolio

Complementing large-scale granulation can be done by adding DEF (also known as AdBlue®) production to a urea facility. This offers a practical and effective way to diversify output and enhance the overall resilience of the plant. As market conditions fluctuate and product demands shift across regions, the ability to serve both fertilizer and fuels segments strengthens a producer’s commercial position.

Stamicarbon’s DEF production technology stands out from conventional methods by enabling producers to generate ISO 22241-compliant, high-purity urea solution directly from the urea melt without intermediate dilution, blending, or secondary finishing steps. This direct-from-melt approach overcomes a key challenge: standard urea streams often contain impurities such as residual ammonia, biuret, and formaldehyde that jeopardise DEF quality and can damage NOX reduction catalysts. Stamicarbon’s design ensures the urea solution meets purity standards, reducing investment in downstream treatment and minimising operational complexity.

In regions where emissions compliance or commercial demand for DEF is growing, this integration provides urea producers with greater flexibility and profitability, granting access to value-added markets.

Strategic importance of urea finishing technology

As market pressure continues to grow driven by demand dynamics, environmental expectations, and global logistics, Stamicarbon’s integrated approach to urea finishing offers a solid foundation for long-term competitiveness and strategic adaptability.

Stamicarbon’s granulation technology, together with its seamless integration with upstream and downstream solutions, provides a strategic toolkit for fertilizer producers. These technology choices enable operational flexibility, premium product capability, and efficient asset utilisation.