Nitrogen+Syngas 397 Sep-Oct 2025

11 September 2025

Turnaround planning using risk management and cost control

RISK BASED WORK SELECTION

Turnaround planning using risk management and cost control

Becht’s Risk Based Work Selection (RBWS) process is a structured, data-driven method that uses risk and benefit-to-cost analysis to optimise turnaround and maintenance work in industrial facilities, resulting in significant cost savings and improved reliability. Abby King, Clayton A. Smith and Frank Engli demonstrate how, supported by proprietary software, the RBWS approach enhances decision-making, documentation, and cross-functional team alignment, while helping clients achieve substantial reductions in unnecessary work and overall turnaround expenses.

In today’s petrochemical and power industries, sustained long term reliability of facilities is a key to profitability and competitiveness. The cost of unreliability, which includes health, safety and environmental (HSE) incidents, is difficult for even healthy companies to endure, and with investment in the right proactive measures, can be avoided. Risk based work selection (RBWS) is a work process that prioritises and optimises turnaround and maintenance work without sacrificing reliability. RBWS uses risk to screen individual worklist items to ensure they are justified by either HSE risk reduction or financial benefit to cost analysis. Significant reductions in turnaround work scope typically result from this structured work process. At the same time, the nature of the process is such that there are numerous additional benefits such as ‘sleeper’ risks not previously considered, minimising discovery work, and helping with alignment of the cross-functional teams.

Inconsistent methods for screening turnaround and maintenance work can lead to missed opportunities for risk reduction and a poor return on investment (ROI). Becht’s RBWS method is a systematic and consistent approach to screen turnaround work lists using historical and industry performance data. Becht’s reliability/maintenance and turnaround specialists have reviewed turnaround work scopes for over 20 years. Becht has deep experienced facilitators with strong risk-based inspection, maintenance, turnarounds and facilitation backgrounds.

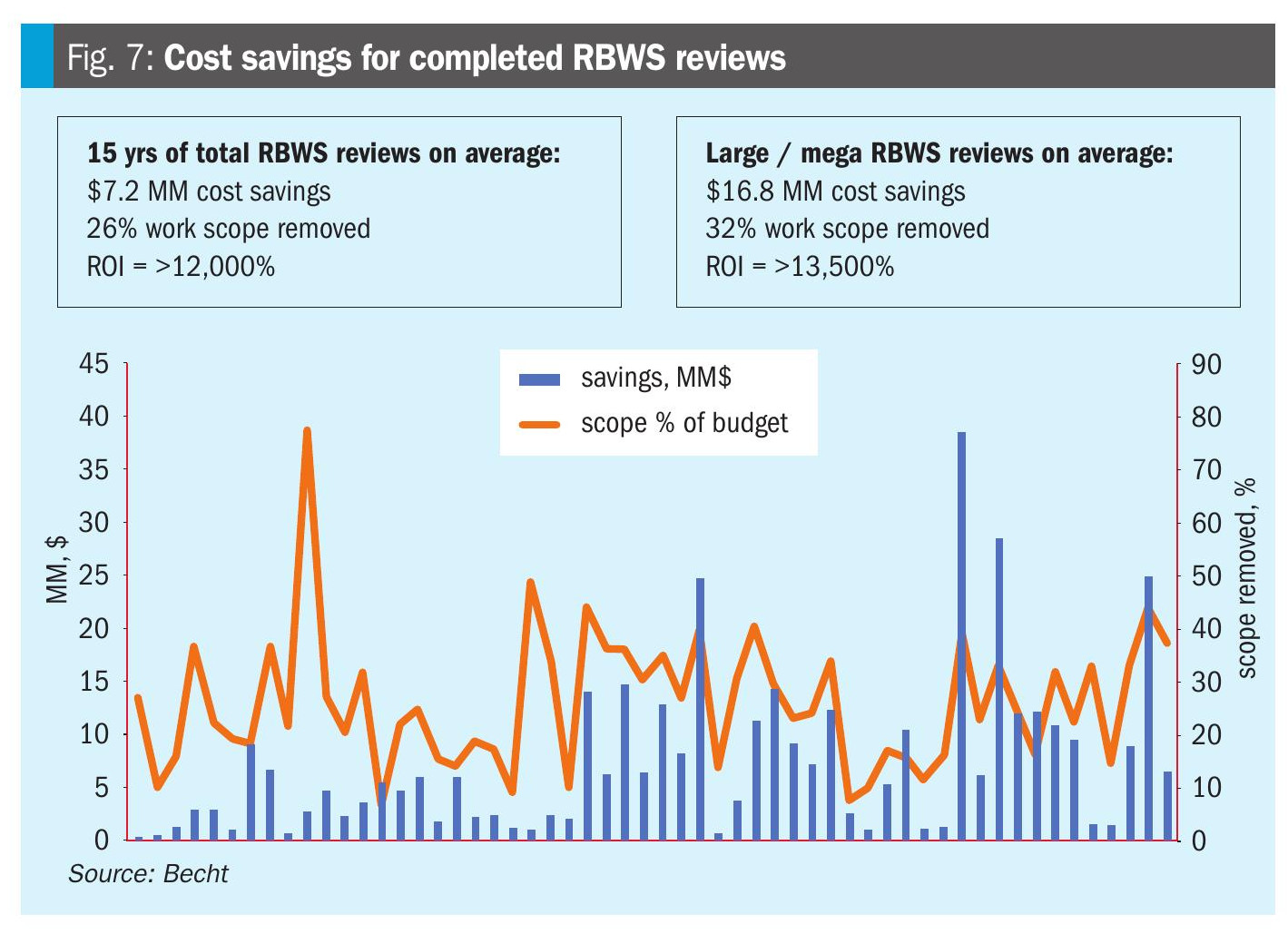

Becht’s average work list optimisation is an average of $7.2 million in reduced turnaround spending per review with a reduction of 26% of low ROI work list items.

Clients often get a ROI of greater than $12K for every dollar they spend doing an RBWS review. Several of Becht’s clients have saved over $100 million in total turnaround costs over a two-year period, by using the Becht RBWS process.

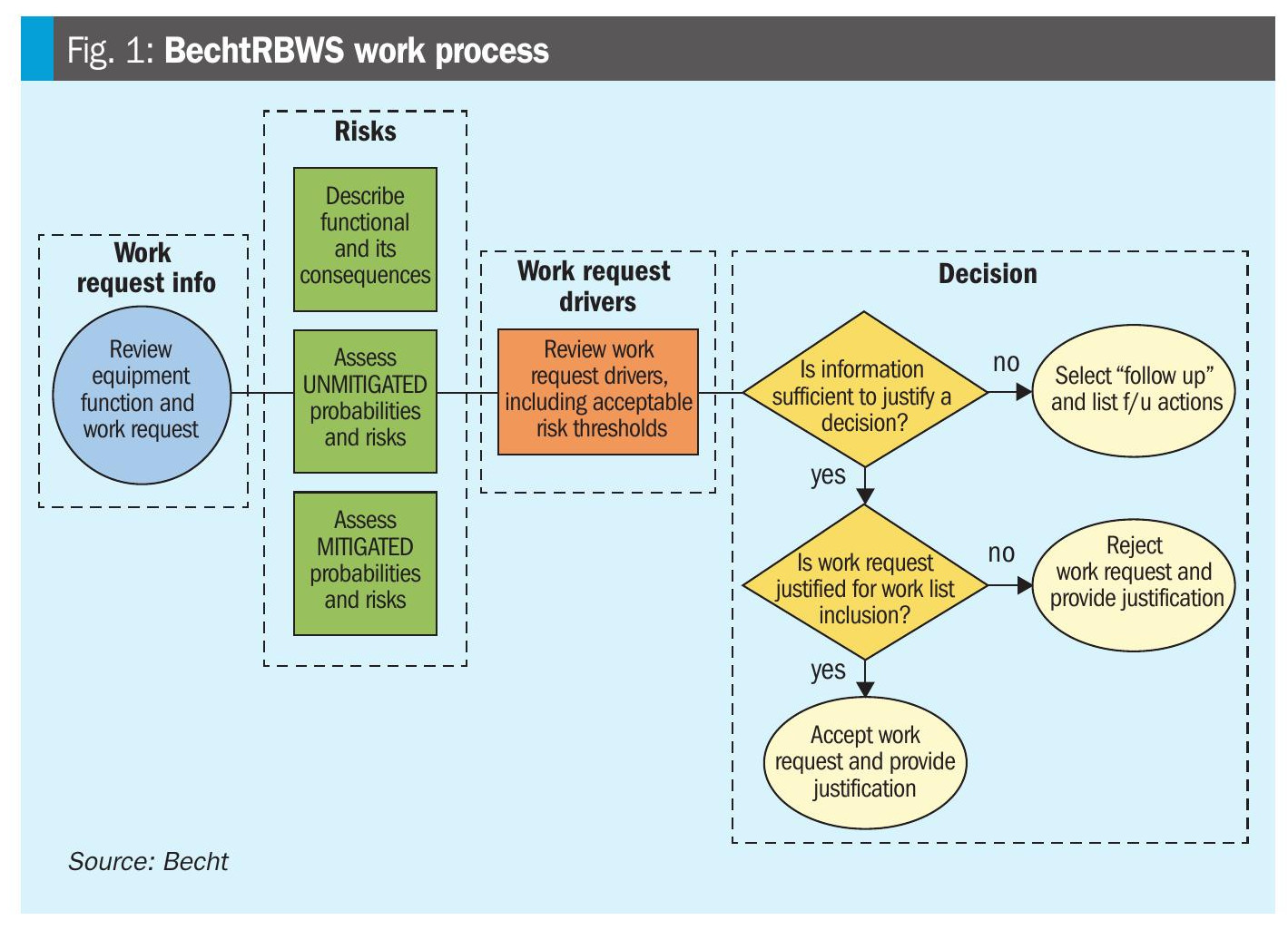

The RBWS process is data driven, ensures consistency of decision making and results in a risk-optimised worklist. The process includes consideration of risk management, reliability and conservation of financial resources. The results are fully documented for leadership review and future turnaround planning. Fig. 1 shows the RBWS work process.

- Can the work be done cost effectively on-stream rather than during the turnaround?

- Does the Risk of deferral meet the HSE threshold?

- Is there a clear justification for the work?

- Is the scope and cost well-defined?

- Is there a clear mitigation of consequences from doing the work?

- Is the cost for the doing the work meet the client’s benefit-to-cost ratio threshold (this consideration only applies when HSE risk is below threshold)

- Will the work eliminate a bad actor?

RBWS is a process which is not limited to fixed equipment but covers all equipment classes (see Fig. 1).

Becht’s approach to RBWS is to combine an SME knowledge based approach with the right tools for consistency, documentation, and ease of facilitation.

The software tool

Use of the right software tool saves time and improves the results of the RBWS review. Becht’s RBWS process uses the proprietary web-based software tool, BechtRBWS, to achieve consistent and efficient facilitation of cross-functional meetings, store the worklist data, and document decision making and results. Documentation of the rationale allows the leadership team to understand the ‘whys’ of the outcome, develops consistency between disciplines and sites, and provides a roadmap for future turnaround planning.

The information necessary to conduct an RBWS should already exist. The challenge is digging the information out of desk drawers, databases, and Excel spreadsheets, and organising it for review during the RBWS. No other tool in the refinery has the structure and required fields to capture the specific subset of data needed for the RBWS. RBWS assessments are for a very specific timeframe; one turnaround cycle, usually 4-7 years.

The software will have this timeframe built into it. The BechtRBWS tool also has the ability to document the unit economics and turnaround premise guidelines into the tool for that can be referenced for future turnaround events or updated if the event timing has changed.

What characteristics should an RBWS tool have?

Documentation – An RBWS session is only as good as the documentation. Being transparent about the team’s thought process and recommendations enables leadership to make informed decisions on what is “in” or “out” of a turnaround and why. Proper documentation helps eliminate recycling before and during the turnaround and can also be used as the starting point for future turnarounds. A dedicated tool preserves the data and results of the RBWS. This is commonly seen as an underlying benefit to clients as time between final scope approval and the RBWS Review increases.

Data gathering – A dedicated software tool should lessen the burden of data gathering for RBWS. Well defined data fields, along with examples, help guide teams during the data acquisition phase. Becht recommends that teams new to RBWS should have training on the process and the data that they are required to gather. Setting clear expectations for the data to include in work scope submittals will help minimise rework and help communicate the expectation that work items will be scrutinised and require justification.

Facilitation – RBWS requires input from a cross-functional refinery team with several members participating in a session at any given time. Therefore, being efficient is critical to a successful RBWS. The RBWS tool should ease the data entry, facilitation, and risk calculations done during a session, minimising the downtime. Toggling between screens and scrolling back and forth takes time and can be distracting and confusing. An ideal tool will have a single screen that is the focus during the session.

That screen will present the data that was pre-loaded along with fields that capture the discussion during the session and show the risk assessment results.

Accessibility – Sharing information across a site or from site to site can add a lot of value for improved workflow, “lessons learned”, benchmarking, and to leverage work products from a past turnaround for a future turnaround. An RBWS tool should enable this by being accessible. Web-based tools that can be logged into from anywhere have a distinct advantage over tools that are loaded onto a single computer.

Reporting – A software tool should have reporting capability built-in so it can roll up results that show the items reviewed, deferred, or recommended to be in/out of the turnaround.

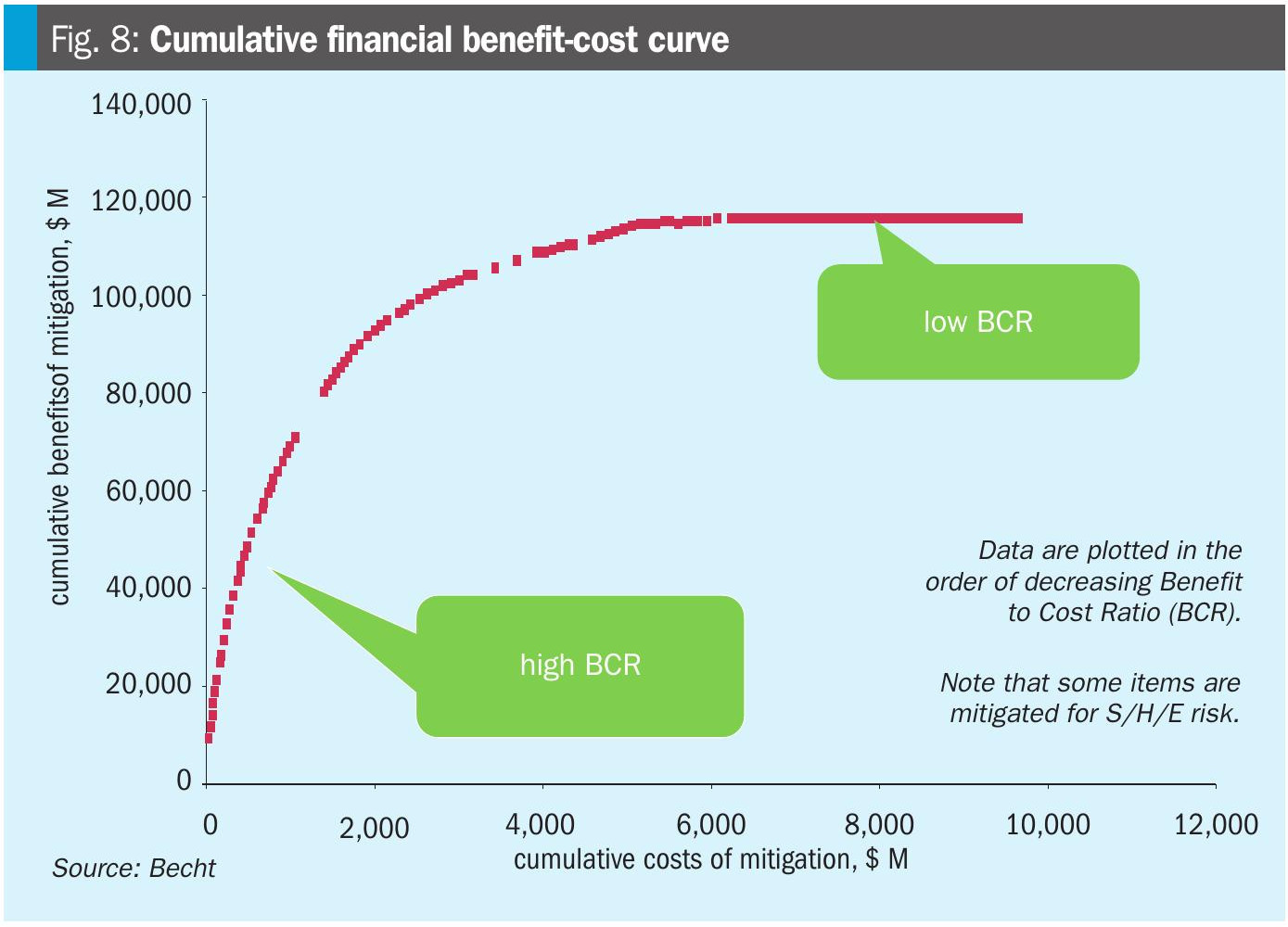

Most software have standard report templates but having the ability for customised reports is a beneficial feature. An example of a report that clients like to see is the benefit to cost graph, which plots each discretionary item in terms of cost versus financial risk mitigated (i.e. benefit), see Fig. 8.

Preparation

The cross-functional team consists of an expert facilitator leading a group of refinery operations, maintenance, technical supervisors, and subject matter experts. As a team of plant personnel participates in the review, developing an efficient process is critical, to minimise meeting time. There are preparation steps recommended so the team can hit the ground running upon starting the RBWS review.

Worklist data – During the review, the drivers (process or equipment integrity) for the turnaround work items are evaluated. The risk-based process is structured to challenge the work list items and determine whether the turnaround work is justifiable, or whether deferments are permissible. Effective evaluation of the drivers requires the right information. Thus, the data should support the evaluation of the benefits of performing the tasks versus deferring the item until the next turnaround. In addition to work scope item description, hours to complete, cost estimate (±30% is recommended), a description of “what will happen if this worklist item is not performed” is required. Also, for each common type of turnaround task, Becht provides specific direction on the information required. For example, in order to justify a heat exchanger cleaning the following information and data is requested:

• Past history

• Service (clean/dirty)

• Monitoring/data such as pressure drop over time

• Percent slowdown or shutdown and time to clean

• U-values or the ratio of ∆Temperature to ∆Temperature at design

The RBWS input workbook is reviewed by the Becht team and there is typically a back-and-forth finalisation of the data prior to the review session. For a site which doesn’t have experience with the RBWS process, it typically takes two weeks after the first worklist is provided to fully prepare for the review. The worklist, when complete, is imported into the web-based application.

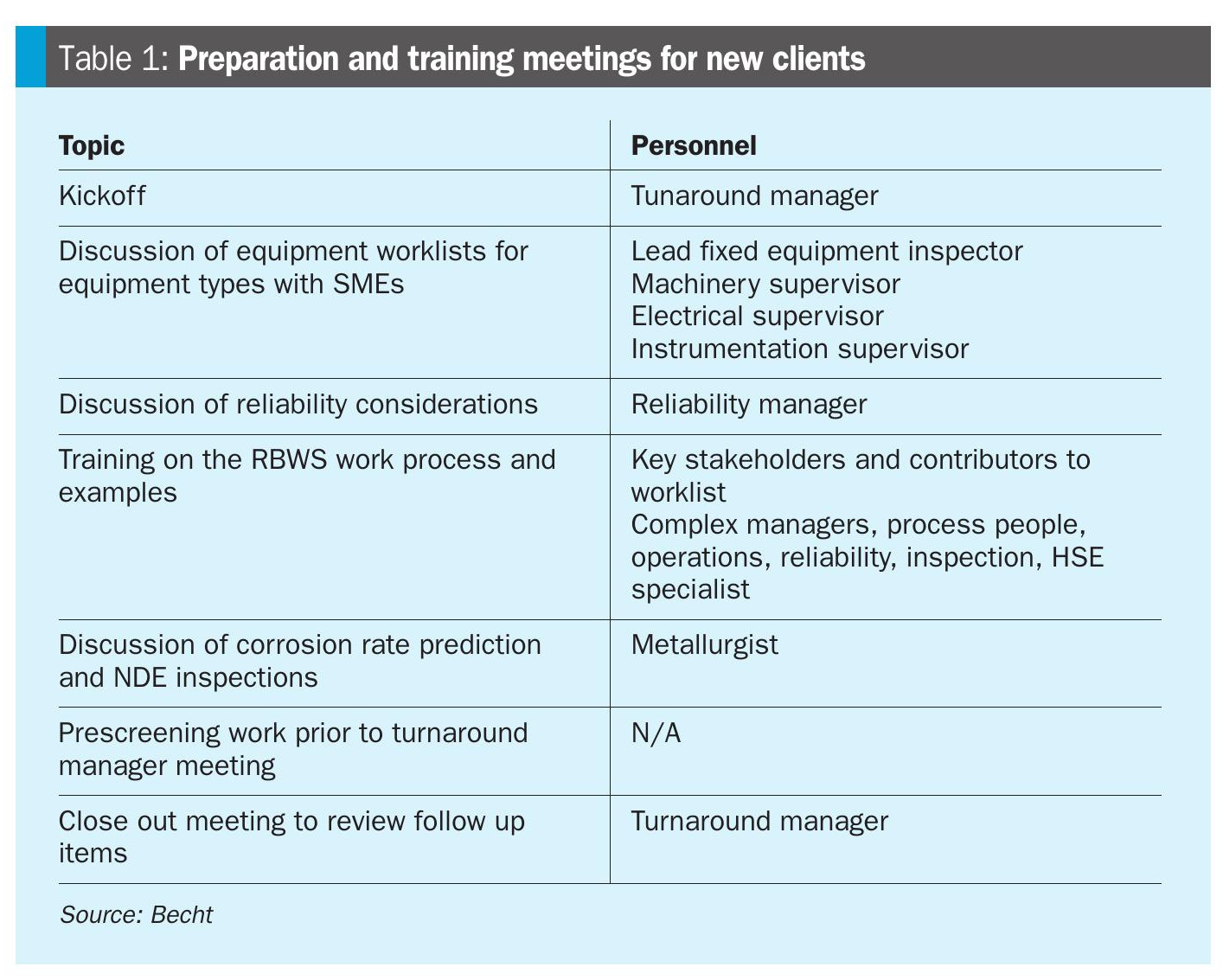

Training and preparation – For sites that have not been through the RBWS process, an on-site or webinar-based series of meetings is highly recommended prior to the review. The training should educate the participants, see Table 1 for typical participants for training, so that expectations for the meeting are understood. The site’s goals for the turnaround and reliability considerations are reviewed with the leadership team.

Prescreening is also one of the preparatory steps where items that are deemed essential to the turnaround are taken out the review process and automatically accepted into the finalised turnaround worklist. Becht develops the list of prescreening criteria with the client and culls the list of items that will be covered during the review. Example criteria include: (1) Very low-cost items that don’t warrant review and (2) Items required for regulatory compliance. This reduces the scope of the review and meeting time, while maintaining the full value of the RBWS review.

Risk basics

Risk is the fact that something bad can happen.

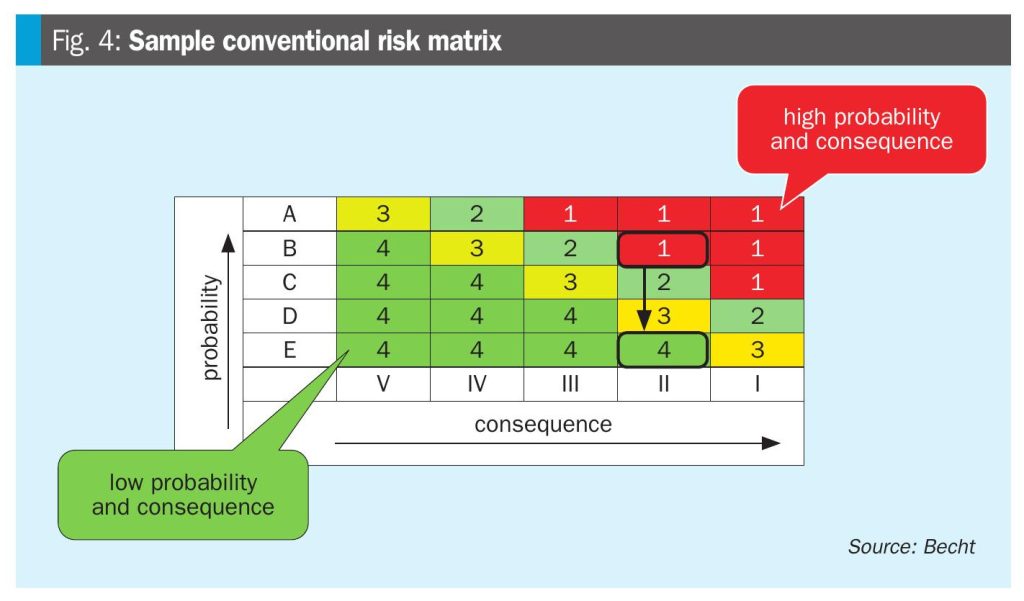

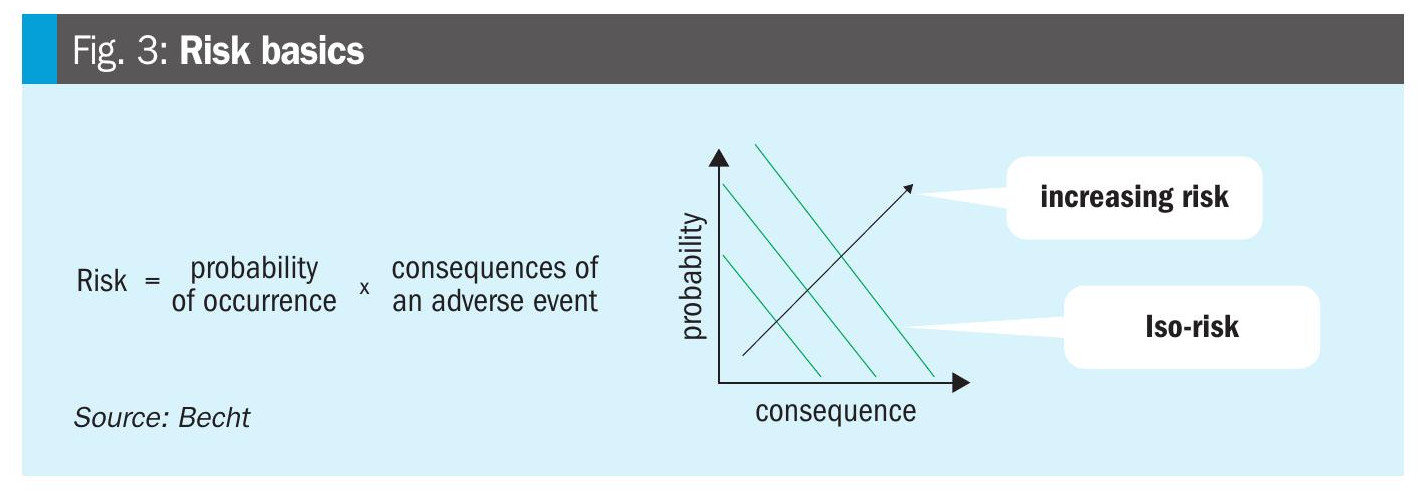

Risk concepts should be well understood by the cross functional team. It is formally defined as the probability times consequence, with respect to an adverse event (see Fig. 3).

Development of risks during a risk-based work process requires defining some of the following information:

• What can happen? Consider the initiating and cascading events, contributing factors and outcome.

• What are the consequences? Quantify the HSE and Economic Consequences.

• What is the likelihood, or probability of the failure scenario?

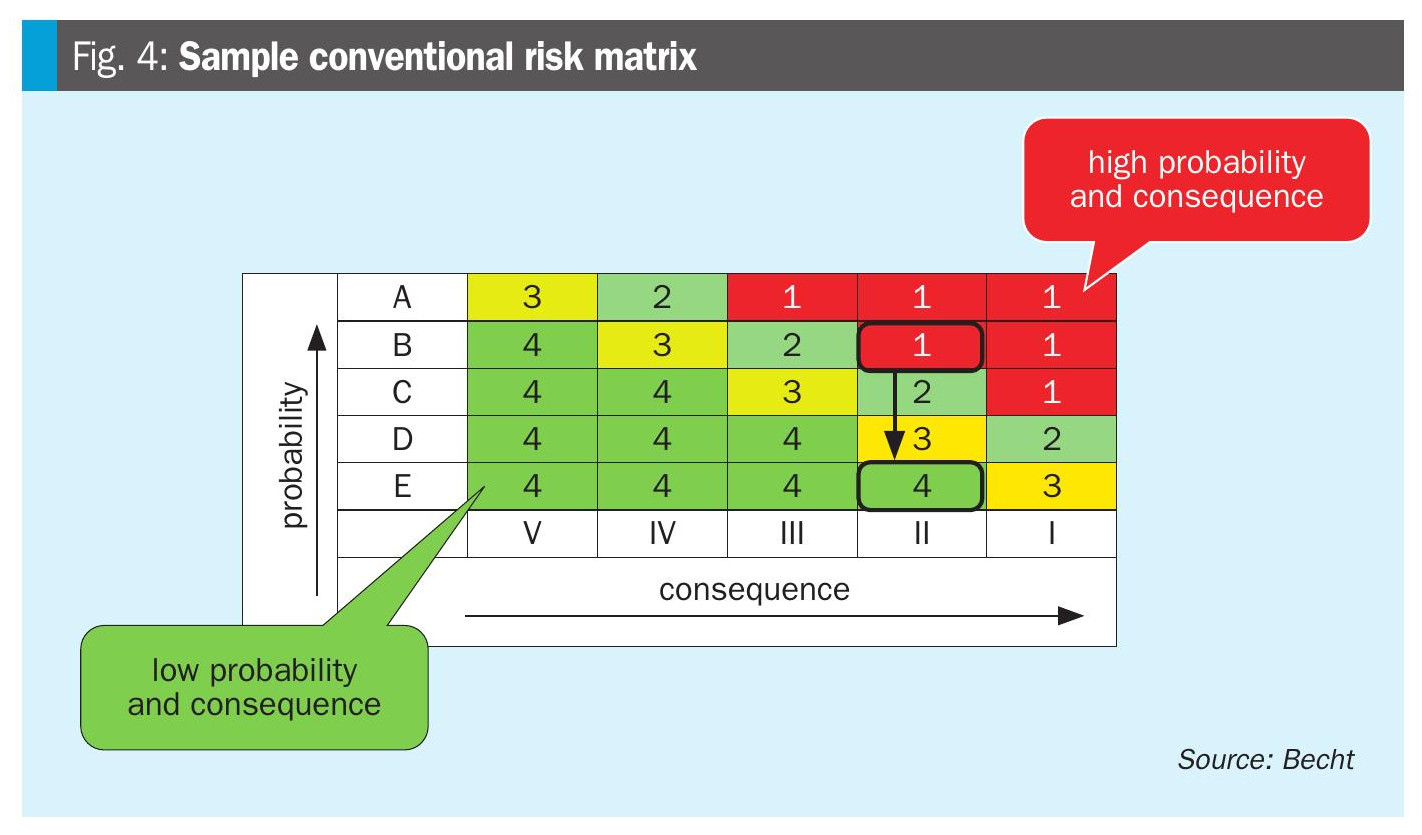

A risk matrix is required to provide structure to the evaluation. The BechtRBWS software dynamically imports any conventionally designed risk matrix such as the sample shown in Fig. 4.

BechtRBWS includes a risk calculator, which is based on the client’s risk matrix and risk definitions, so that the cross-functional team can estimate business and HSE risk levels. In calculating risk, the probability and consequence categories are combined, and unmitigated and mitigated risk levels are displayed. Both economic and HSE risks are used.

The benefit to cost ratio (BCR) is the benefit of mitigation (reduction in business risk) divided by the cost of the task. The cross-functional team uses the BCR along with other considerations (unmitigated HSE risk, cost of action item, bad actor resolution, etc.) to make the determination whether the task is in-scope based on previously developed task acceptance criteria. The group should clearly document a justification for the decision. Ultimately the important considerations from a risk perspective is:

- HSE risks are mitigated to achieve acceptable risk levels.

- Business risks are mitigated based on ROI, or BCR.

Consequence evaluation

Becht has an in-house methodology to determine consequences for loss of containment incidences. An automated part of the BechtRBWS tool which considers fluid properties (flammability, toxicity and vapor cloud potential), pressure and size of expected leak are considered to determine the consequence category in accordance with the client’s consequence category definitions.

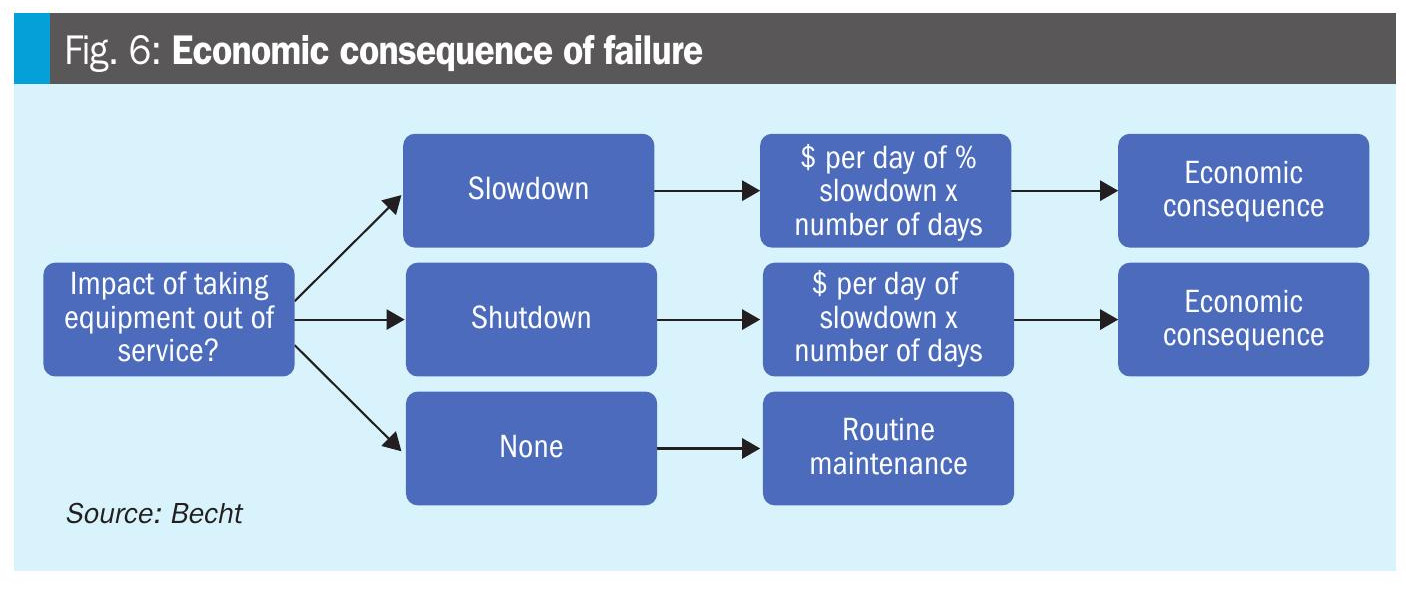

Economic consequences are used in calculating the Benefit to Cost Ratio (BCR) for discretionary work list items. The lost profit opportunity for a slowdown or shutdown is provided for this calculation and the steps in Fig. 6 are followed to calculate the potential economic consequences of failure.

When determining the number of days for the shutdown or slowdown it is important to consider how much time is needed for operations to isolate and decontaminate the equipment for maintenance, inspection to determine repair scope, days of maintenance to conduct repairs, any special considerations for the equipment such as post weld heat treatment of weld repairs, and the time it takes to return the equipment to service. As an example, depending on geographical location, complexity of the unit, and equipment considerations a typical outage duration for a drum is 7-10 days, whereas a tower could take 14-21 days depending on size.

Outcomes and case studies

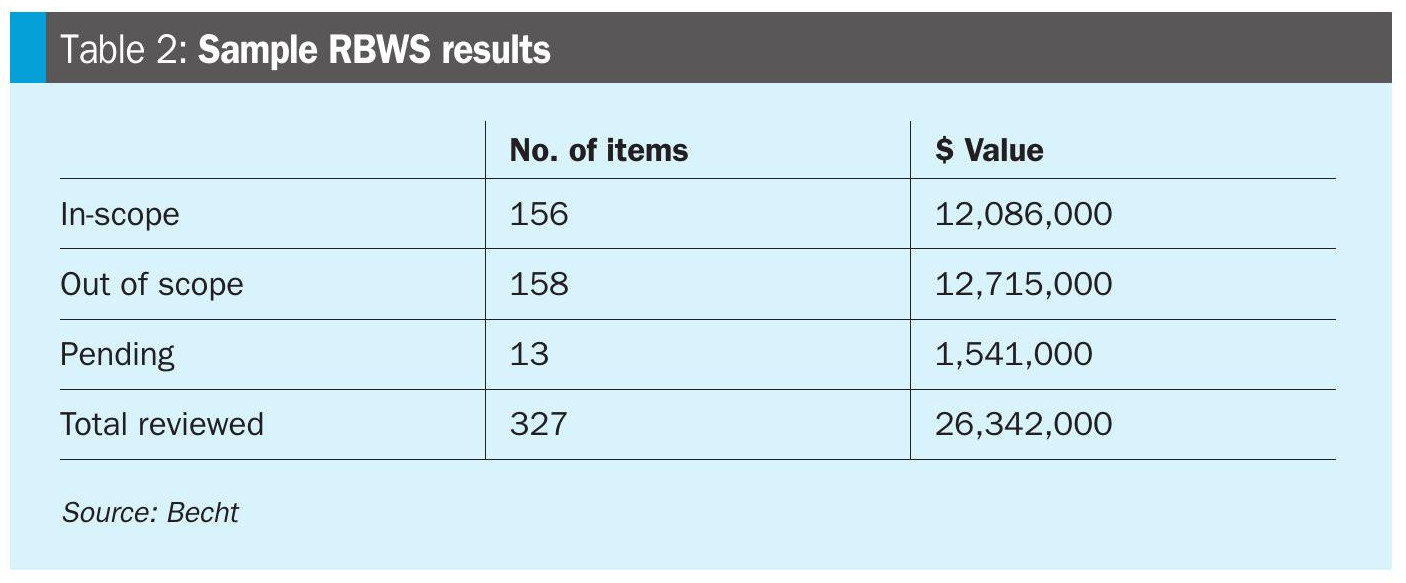

An RBWS assessment for a major turnaround (> 500,000 MHrs) is likely to take as much as two weeks, provided the front-end planning and prescreening are effectively completed and the items on the worklist are of a requisite quality. Fig. 7 plots the task cost savings achieved as an outcome of a series of completed RBWS reviews by unit/turnaround block event. Table 2 shows sample results of a recent RBWS.

The results in Table 2 are from a one week RBWS where the list was prescreened by the site. The first step in RBWS is determining if the work can be executed on the run with little or no impact to production. Items that can be executed on the run can then be prioritised by routine maintenance for execution. One of the main drivers to execute work outside of the turnaround is a reduced cost. Experience in industry indicates that routine maintenance work is at least half the cost of turnaround work, and depending on sites region, turnarounds can be as high as four times the cost of doing the work compared to work done in routine maintenance.

At this particular site frequent inspections have been done in the past, providing the opportunity to reduce turnaround activities without accepting substantial risks. It was also identified that there was significant potential for discovery work in one of the units due to several process upsets over the last run.

Fig. 8 plots the work list tasks in the order of decreasing benefit-cost ratio (BCR) and illustrates the diminishing return nature of risk mitigation. This automated output from the RBWS work process allows plant managers to conserve maintenance resources and minimise risk by targeting the high return work list items (corresponding to the left side of the figure). Note: Fig. 8 does not consider HSE risk drivers, which are considered independently.

Summary

Becht’s data driven RBWS method is a systematic and consistent approach to screen turnaround work lists. The process is facilitated by Becht’s reliability/maintenance and turnaround specialists, who have decades of experience in execution of RBWS and turnaround planning.

RBWS uses risk to screen individual worklist items to ensure they are justified by either HSE risk reduction or financial benefit to cost analysis. Significant reductions in turnaround work scope typically result from this structured work process. At the same time, additional benefits such as identification of ‘sleeper’ risks, minimisation of discovery work, and alignment of the cross-functional teams on a consistent approach for turnaround worklist development are realised through adoption of the Becht RBWS process.