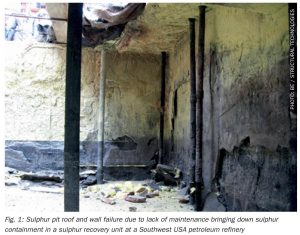

Sulphur pit turnaround and rehabilitation

A full sulphur pit turnaround and rehabilitation is typically a once in a lifetime experience for refinery personnel. Specialists in sulphur pit turnarounds, Gavin Palmer of Brindley Engineering, Tom Kline and Bob Hall of Structural Technologies have compiled a database based on multiple sulphur pit turnarounds to identify typical deficiencies in mechanical systems, along with improvements to enhance operability, restore functionality and meet all codes/standards and best practices.