Fertilizer International 528 Sep-Oct 2025

11 September 2025

Modernising urea plants

AFA TECHNICAL CONFERENCE

Modernising urea plants

Revamping existing urea plants can deliver significant improvements – be it higher capacity, lower costs, or reduced emissions. These upgrades are essential for operating companies seeking to stay competitive, meet new regulatory standards, or make better use of existing assets. Marc Wieschalla of thyssenkrupp Uhde provides an overview of the main revamp options.

Revamp objectives

Urea plant revamps can deliver:

- Increased production capacity

• Cuts to operating costs (e.g., through energy efficiency)

• Reduced environmental emissions and decarbonisation of production

• Improved plant availability and reliability

• Expanded product output(e.g.,AdBlue® , melamine)

• Modernised plant control systems.

Increasing plant capacity is the most frequent revamp goal – as the additional output quickly pays off the original investment. Key targets for revamps at urea production sites include melt plants, granulation units, and the CO2 supply.

Revamp strategy – a four-step approach

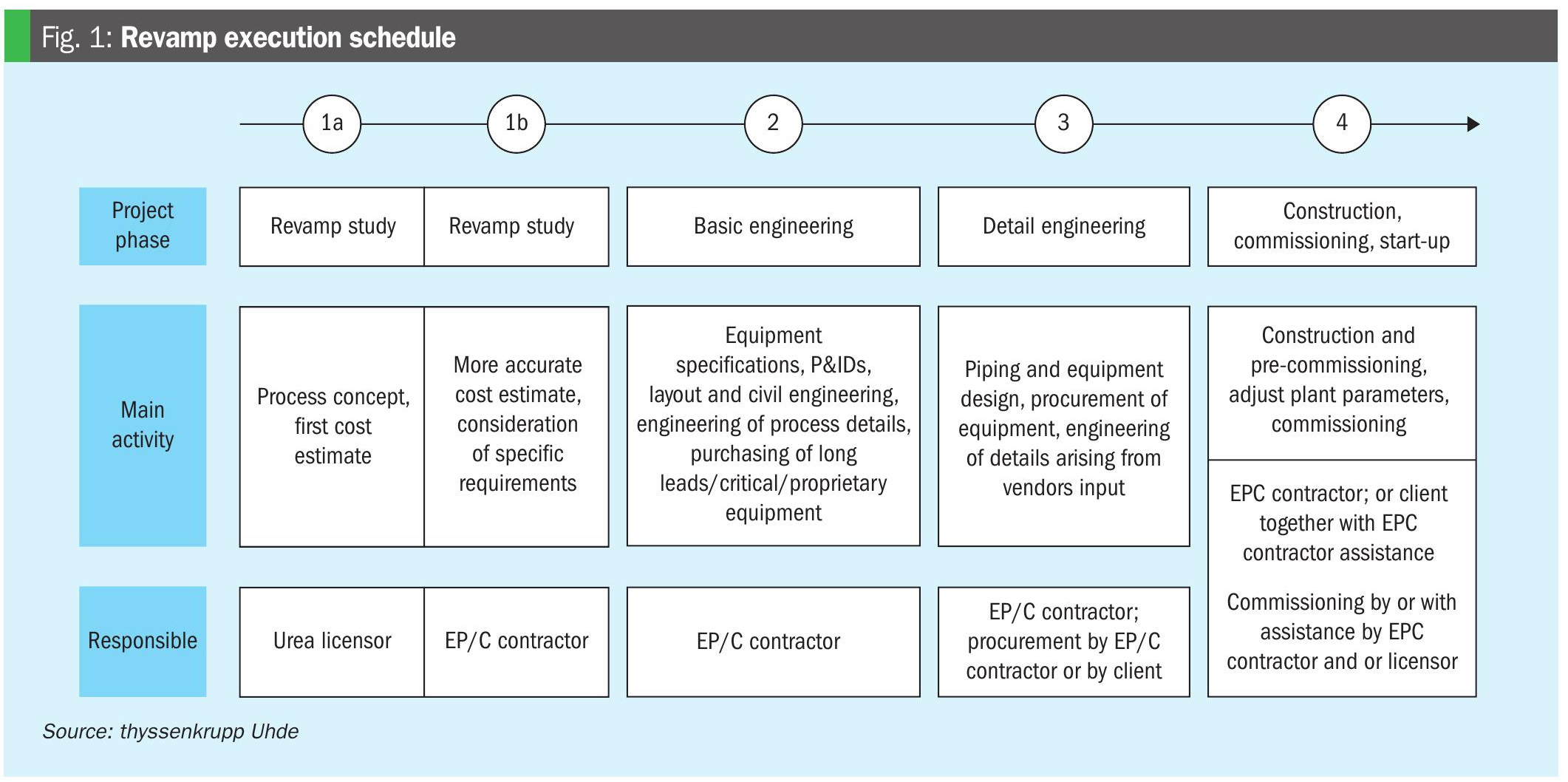

A typical revamp project proceeds in four steps as follows (Figure 1):

Revamp study (1a & 1b): Initial evaluations define the process concept and provide preliminary cost estimates (1a). Early involvement of the engineering, procurement and construction (EPC) contractor can scope utilities, space, and downtime constraints to provide a more accurate cost estimate (1b).

Basic engineering (Step 2): Initial equipment (especially long-lead items) is selected and purchased, based on the process design package (PDP) and the EPC design concept.

Detail engineering (Step 3): Full-scale engineering and equipment procurement are carried out. Some purchasing by the client may also occur at this stage.

Construction, commissioning & start-up (Step 4): New components are installed and tested. Commissioning services from the EPC contractor and/or licensor can range from advisory support to full-service handover.

Revamping the melt plant

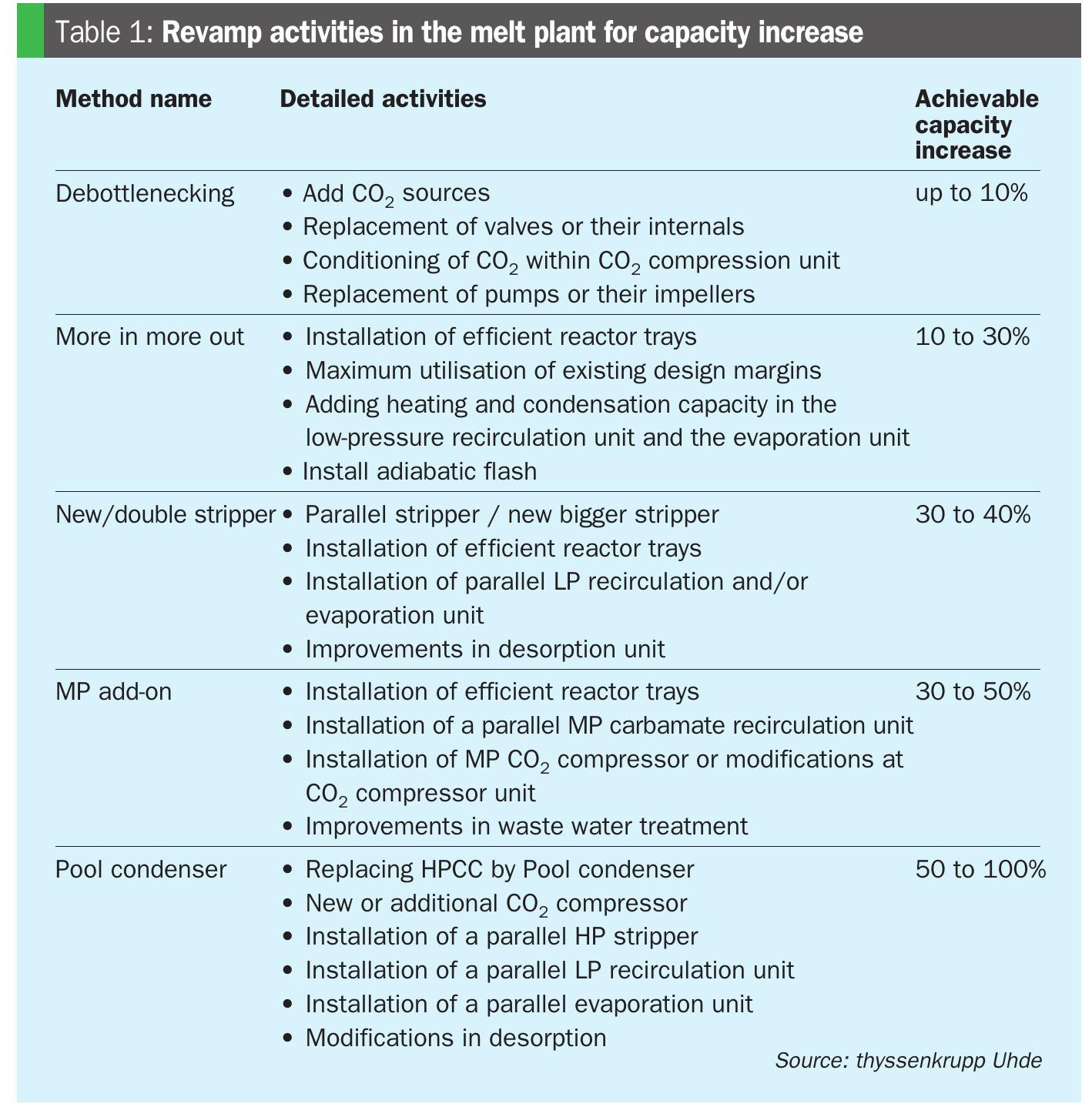

Capacity increases in the melt plant can follow five main paths – as set out in Table 1:

• Debottlenecking

• More in, more out

• New/double stripper

• Medium pressure (MP) add on

• Pool condenser.

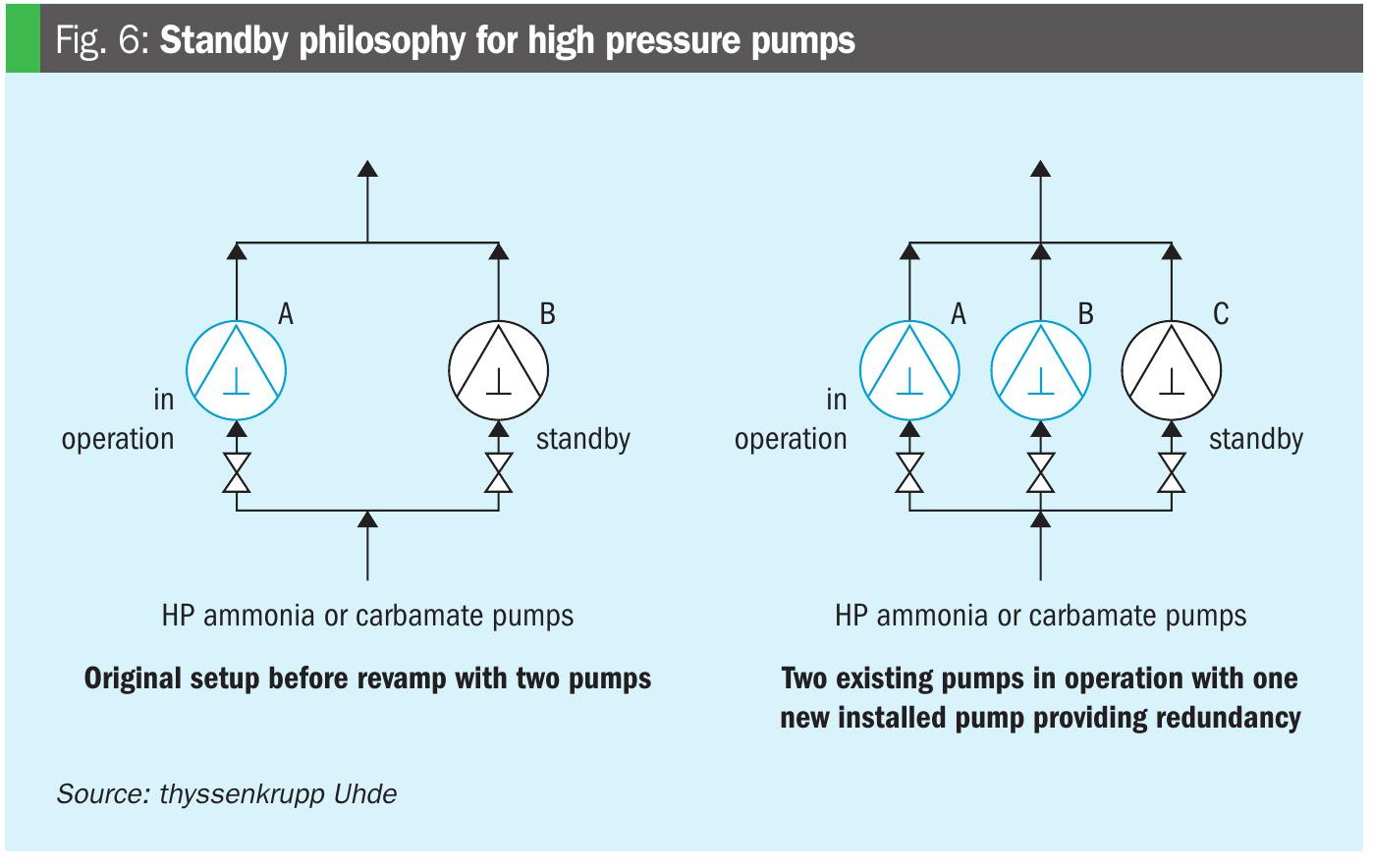

Debottlenecking can increase capacity by up to 10%. It involves targeted upgrades to relatively minor equipment (e.g., valves, pumps) without major structural changes to the urea plant. Larger capacity increases require the involvement of the urea process licensor and significant additions to process equipment.

The other four melt plant revamp options shown in Table 1 can increase the original capacity by up to 100%.

Boosting CO2 supply

Two strategies can provide more CO2 for urea synthesis:

• Ammonia plant CO2 removal units: These increase synthesis gas throughput and reuse fuel gas in reformers to generate more CO2. This is cost-effective when front-end units have sufficient design margin.

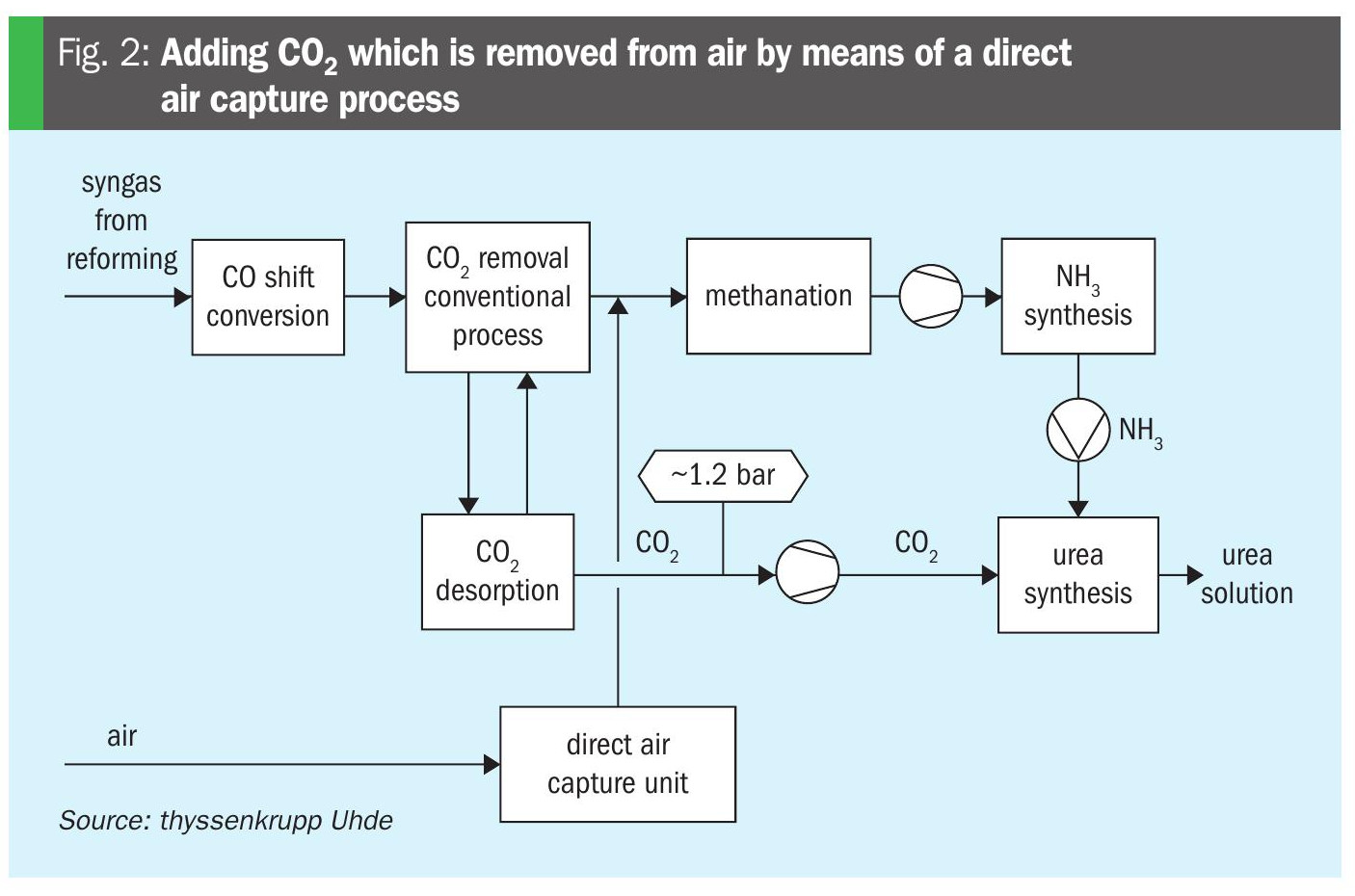

• Direct air capture: Although currently small-scale and high-cost, this emerging technology will make green urea production an achievable goal in future. It removes CO2 directly from ambient air for reinjection into the process (Figure 2).

Revamping the urea granulation plant

Granulation revamps fall into two categories:

• Smaller revamps that increase capacity by up to 15% and avoid major changes new nozzles and cooling upgrades will generally suffice.

• Larger revamps that increase capacity by up to 45% – and may require an extension to the granulator, new fans, added zones, and cooling system improvements.

Emission reductions are often integral. New air fans are typically required to counter the pressure drops from added abatement systems. In many cases, installing booster fans can reduce costs while maintaining flow.

Material handling upgrades also become necessary in larger revamps, although existing spare capacity can be leveraged to minimise investment.

Reducing Emissions

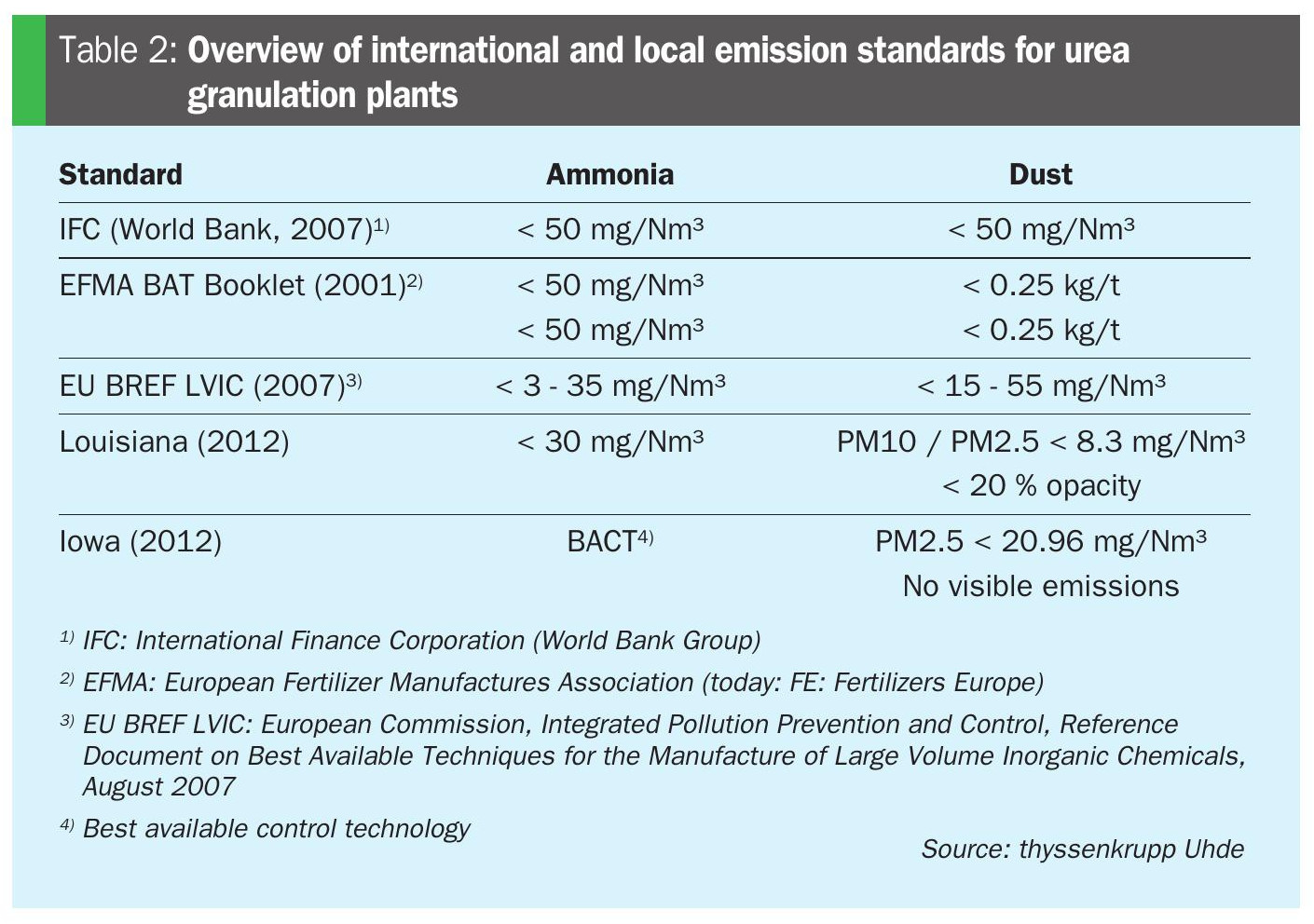

As regulations tighten, particularly for ammonia and dust (Table 2), even older plants must be brought into compliance. Emission points include:

• The low pressure (LP) absorber

• The atmospheric absorber

• The granulation stack.

Ammonia emissions from the absorbers are low in mass but high in concentration due to small gas volumes. Conversely, granulator emissions are higher in volume but diluted.

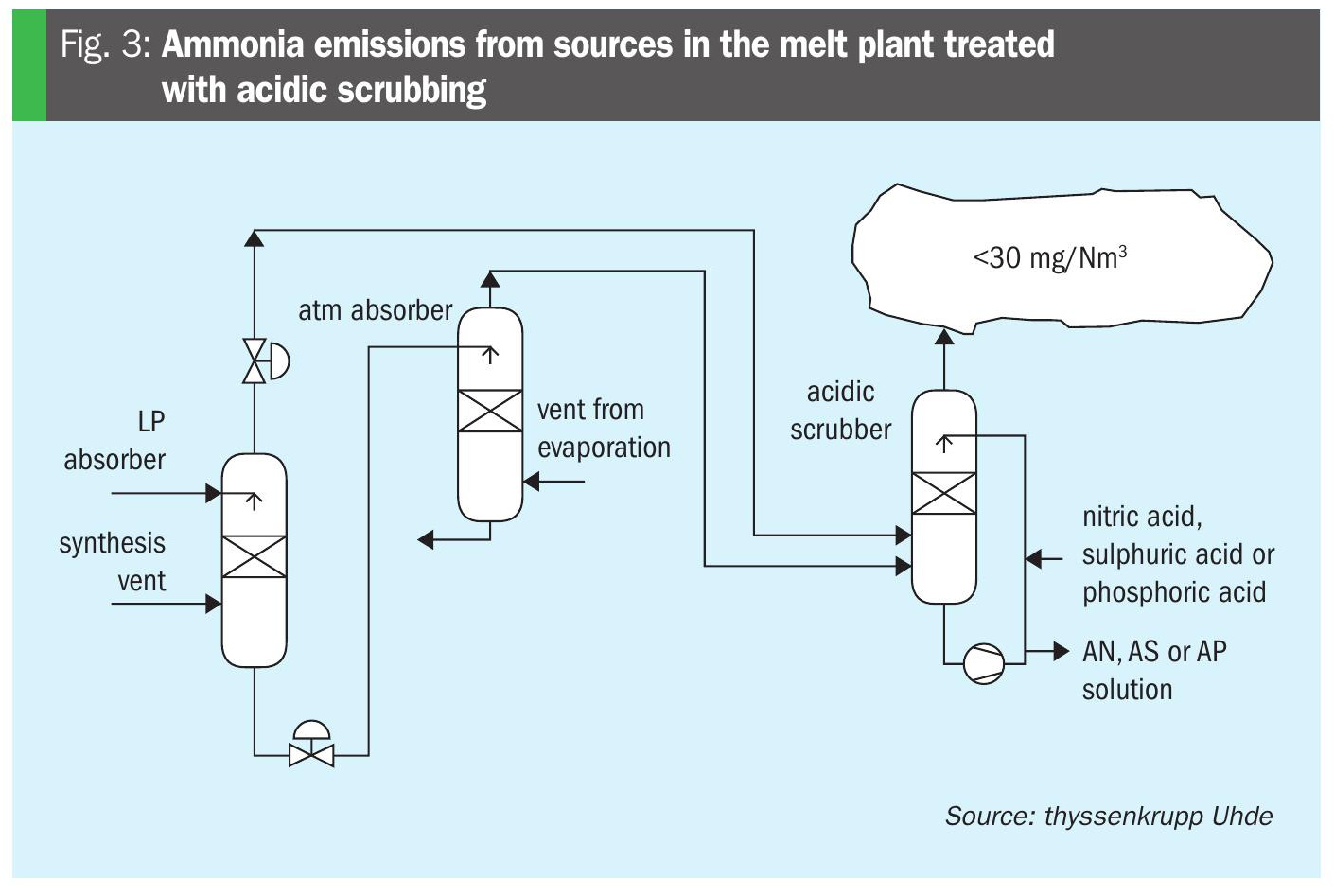

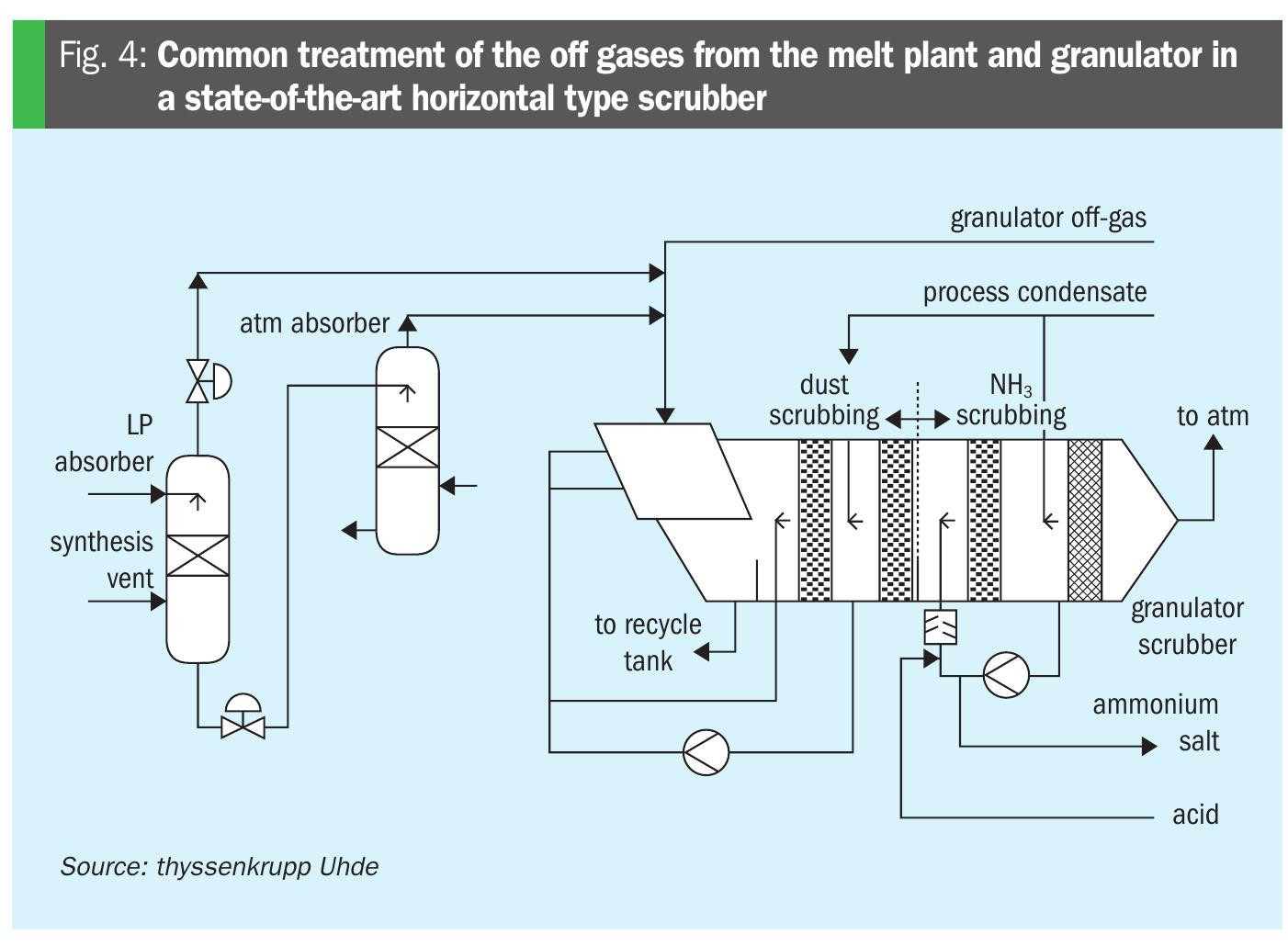

Scrubbing systems (Figure 3 & 4) – modern, multi-stage and acidic – can reduce emissions well below international thresholds. Options include:

• Replacing scrubber internals

• Adding dedicated acid scrubbers

• Installing combined dust and ammonia scrubbers.

In scrubbing, the choice of acid (nitric, sulphuric, phosphoric) depends on:

• Local availability

• Downstream processing capability

• Existing plant materials (e.g., stainless steel grades).

By-products such as ammonium nitrate or ammonium sulphate can be reused, e.g., in UAN production or granulated with urea for additional nutrient content.

Improving plant availability and contractor contributions

Plant availability can be significantly enhanced through modern equipment concepts. A prime example is the self regulating melt pump – which operates with zero suction head (NPSH = 0 metres). This is installed just below the evaporator, allowing direct connection to the granulator’s melt header.

This configuration minimises suction piping while the lower melt residence time also limits biuret formation. The pump’s self-regulating nature also eliminates the need for level control or pump protection, so reducing shutdown risk – this being particularly valuable in plants with variable feed rates (e. g., those with UAN or DEF units). Uhde holds the patent for this application.

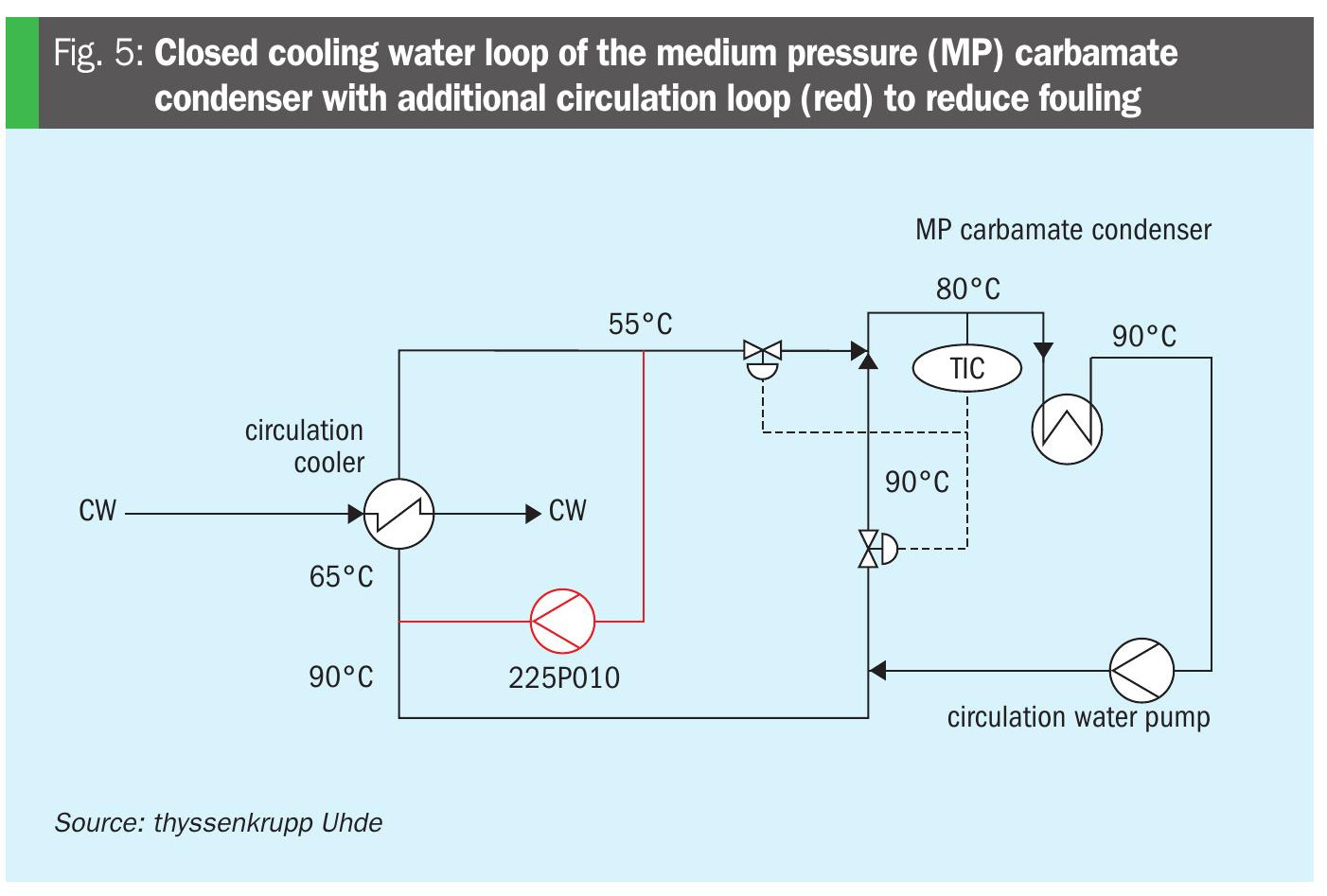

Contractors can enhance plant reliability further during detail engineering. In a medium-pressure (MP) add-on revamp, for example, Uhde has reduced fouling in the MP carbamate condenser’s cooling loop by adding a secondary circulation pump (Figure 5). This reduces inlet temperatures at the plate heat exchanger, lowering the risk of scaling. The same upgrade has been applied to the high-pressure (HP) scrubber and low-pressure (LP) condenser, improving overall plant availability.

Conclusion

Revamp activities are carried out to increase capacity, reduce operating costs, improve plant availability or minimise environmental impact. Early involvement of all parties is essential. With reliable data from the licensor, the contractor can assess feasibility and define required changes. thyssenkrupp Uhde combines customer experience, licensor know-how and its own engineering expertise to ensure a successful and integrated revamp.

Author’s note

For a deeper dive into urea plant revamping, see thyssenkrupp Uhde’s previous article in the May/June 2025 magazine (Fertilizer International 526, p34).

The company will also be presenting on ‘Performance improvement at fertilizer plants by plant digitalization’ at the forthcoming AFA International Technical Conference & Exhibition, Benguerir, Morocco, 16-18 September 2025. The company will also be giving an opening keynote on green fertilizer strategies and decarbonisation.