Fertilizer International 528 Sep-Oct 2025

11 September 2025

Get the most out of your plant

AFA TECHNICAL CONFERENCE

Get the most out of your plant

Casale’s integrated revamp solutions for ammonia and urea plants are designed to unlock latent potential and boost operational performance. Casale’s technology team provides an overview: Dario Di Addezio, Matteo Fumagalli and Francesco Baratto.

A holistic revamp strategy

In the chemical industry, ammonia and urea are crucial foundational products for agricultural fertilizers and a variety of other industries. Their manufacture mostly begins with the steam methane reformer (SMR), a key piece of equipment that produces the hydrogen needed for both production processes. Although built for durability, these high-temperature, high-pressure SMRs eventually encounter challenges due to aging infrastructure and changing market demands. This often leads to reduced efficiency, higher operational costs, and increased environmental concerns.

However, modern revamping isn’t just limited to the SMR either. Significant improvements are also being made to other critical sections of ammonia and urea plants – a holistic approach that ensures overall performance is enhanced across the nitrogen production complex.

Today’s fertilizer producers are under immense pressure to boost capacity, drastically reduce energy consumption, and significantly shrink their carbon footprint. Building new greenfield plants is one solution, but the high capital costs, long timelines, and complex permitting often make it impractical for existing facilities. This makes revamping a strategic necessity.

At Casale, we know that true optimisation means looking at the entire production chain, not just individual units. While the SMR is a clear candidate for upgrades, due to its high energy consumption and critical role, our holistic revamp strategy focuses on synergies across the whole process. This allows us to not only modernise the SMR, but also meticulously optimise other key sections within both the ammonia and the subsequent urea plant.

This article explores Casale’s comprehensive suite of innovative revamping solutions, detailing how our proprietary technologies are applied across key areas. Taking a deep dive into our revamp offerings, with illustrative case studies, we’ll demonstrate how Casale’s integrated approach empowers producers to unlock latent potential, enhance energy efficiency, curtail emissions, and extend the economic life of their entire complex, ensuring they far exceed, not just meet, the demands of a rapidly evolving global market.

The following sections delve into Casale’s proprietary technologies and advanced methodologies – and how, through these targeted interventions, we can empower producers to achieve unparalleled levels of efficiency, sustainability, and operational longevity.

Optimising the steam methane reformer

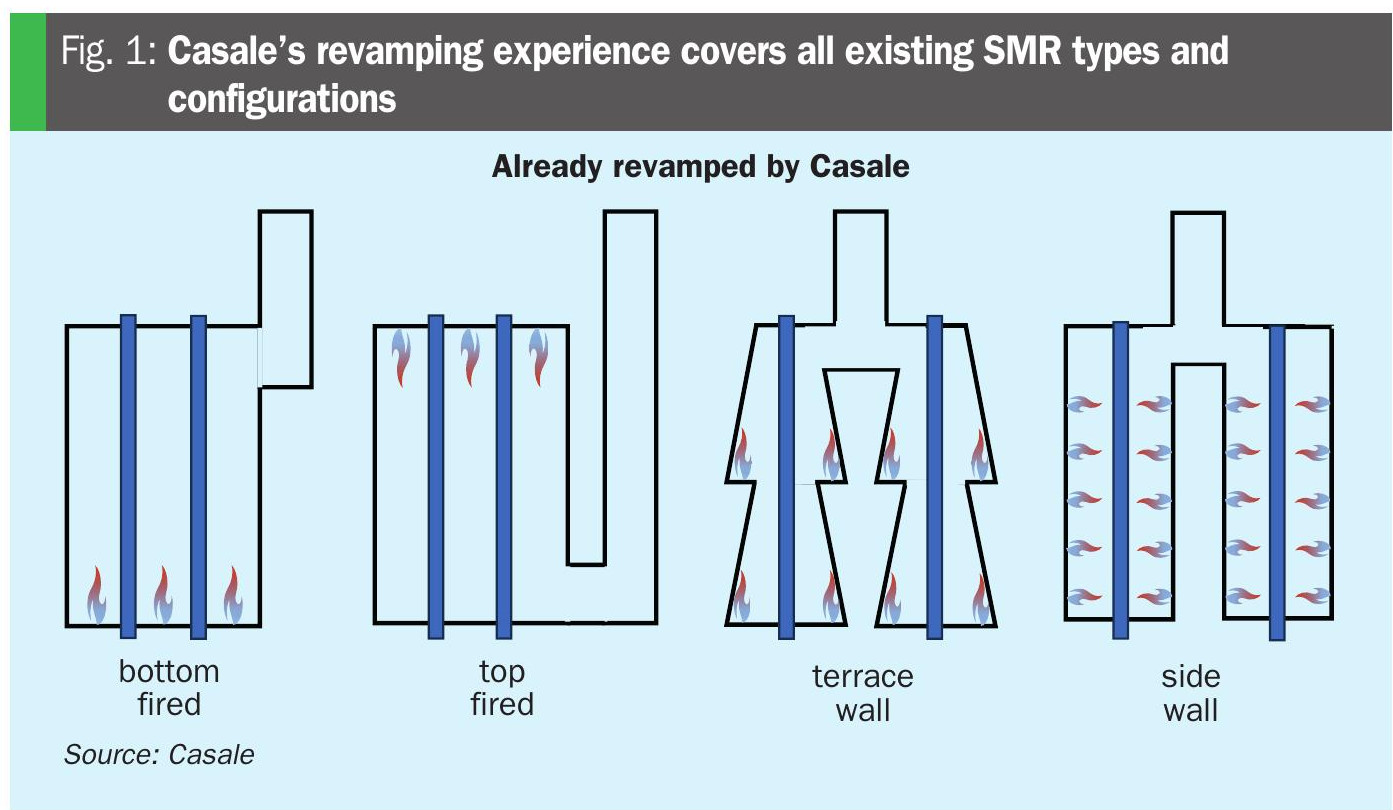

Casale has a unique and well-recognised licensor expertise in revamping steam methane reformers (SMRs) – with a focus on enhancing energy efficiency and performance. The company’s revamping experience covers all existing SMR types and configurations that are currently available and in operation worldwide, including bottom-fired, top-fired, terrace wall, and side-wall designs (Figure 1). This extensive knowledge, combined with our experience and track record building new grass-roots syngas production plants, has significantly strengthened Casale’s understanding of the key equipment for reforming reactions.

Existing furnaces often operate beyond their upper throughput limits. Consequently, many critical components, such as catalyst tubes, pigtails, intermediate tube sheets, and shield coils, are forced to operate very close to their material design limits. Over time, further limitations can arise due to component aging, mis-operation, the constraints of the original design, or new environmental emission requirements.

Such critical conditions can be exacerbated when revamping activities are performed without a proper licensor assessment. In our view, a revamp assessment is fundamental as a way of minimising risks and avoiding unexpected issues with plant consumption figures.

A licensor’s assessment, drawing on a complete knowledge of the plant’s background, identifies symptoms and warning signs, before the point of no return is reached, helping to avoid unplanned outages and potential risks to personnel. This is the crucial first step towards a revamping project. Based on Casale’s experience, it is essential to conduct a detailed data analysis of the entire reformer. This investigation, when performed by a technology licensor with deep plant knowledge, is vital for identifying abnormal conditions, design limitations, or upset operating parameters that could impact the entire plant.

Casale’s revamping strategies are specifically designed to address these challenges, with the goal of improving energy efficiency, increasing capacity, and reducing both the carbon footprint and emissions.

The company’s expertise in primary reformer revamping is unparalleled. Our work on revamping existing plants has significantly enhanced our knowledge of key reforming equipment. In fact, Casale is the only licensor with recognised revamping expertise across all existing SMR types and configurations (Figure 1), making us a leader in the field.

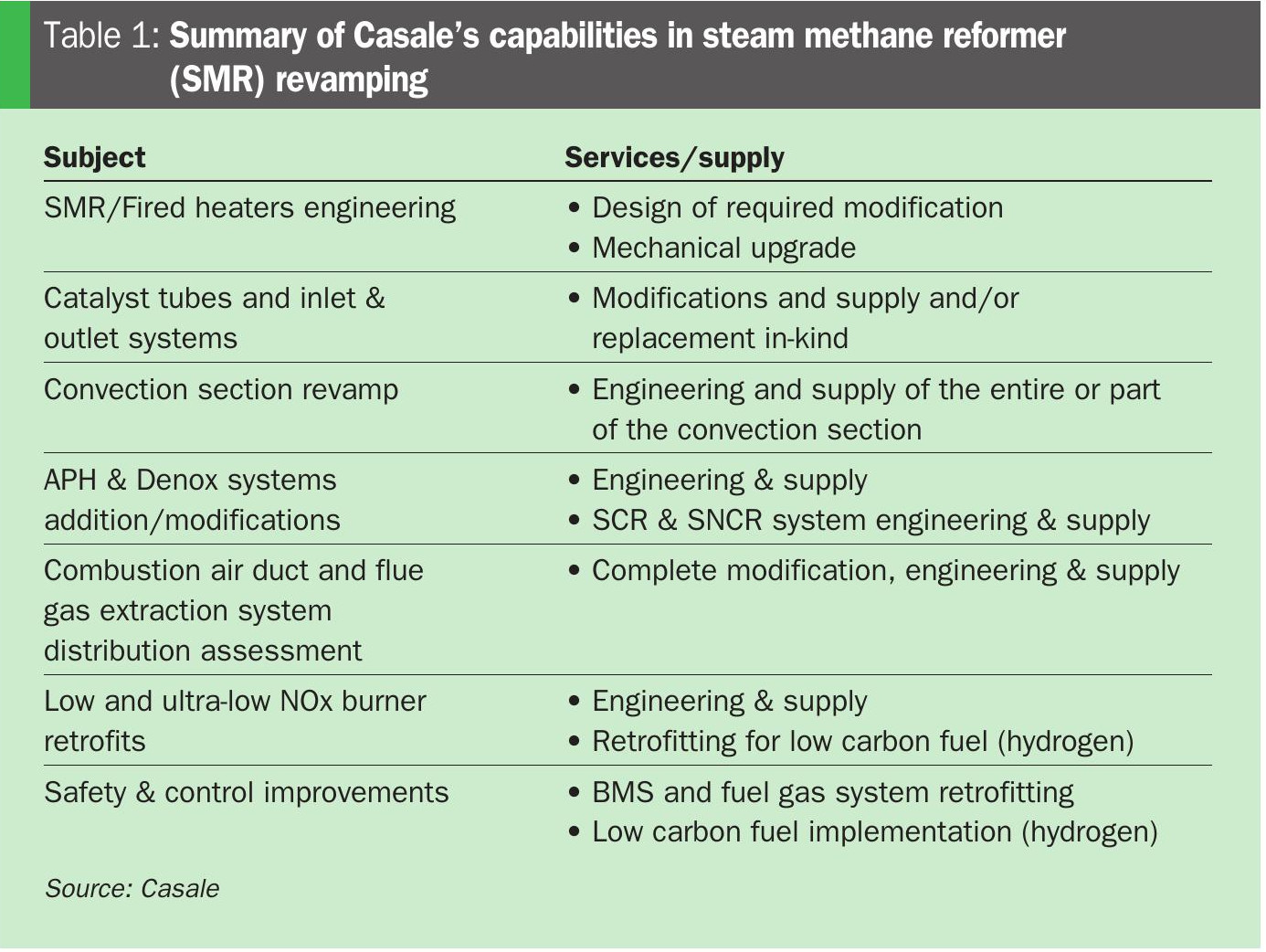

The scope of a primary reformer revamp typically requires a multi-faceted approach, with a range of services and supplies, as outlined in Table 1.

The radiant chamber is the most expensive and critical section of the primary reformer – incorporating materials designed for high-temperature strength, creep resistance, and resistance to carburisation or embrittlement. Casale has accumulated experience in designing the modifications and mechanical upgrades necessary for operating plants at higher temperatures and pressures, to either improve the reaction or increase efficiency and tube life.

In many instances, modifications are not just limited to the high-alloy pressure parts, they are also carried out on the combustion air distribution system, burners, and the flue gas extraction system. Casale’s assessment capabilities combine thermal primary reformer analysis jointly with mechanical analysis and computational fluid dynamic (CFD) analysis which covers the radiant chamber’s heat distribution.

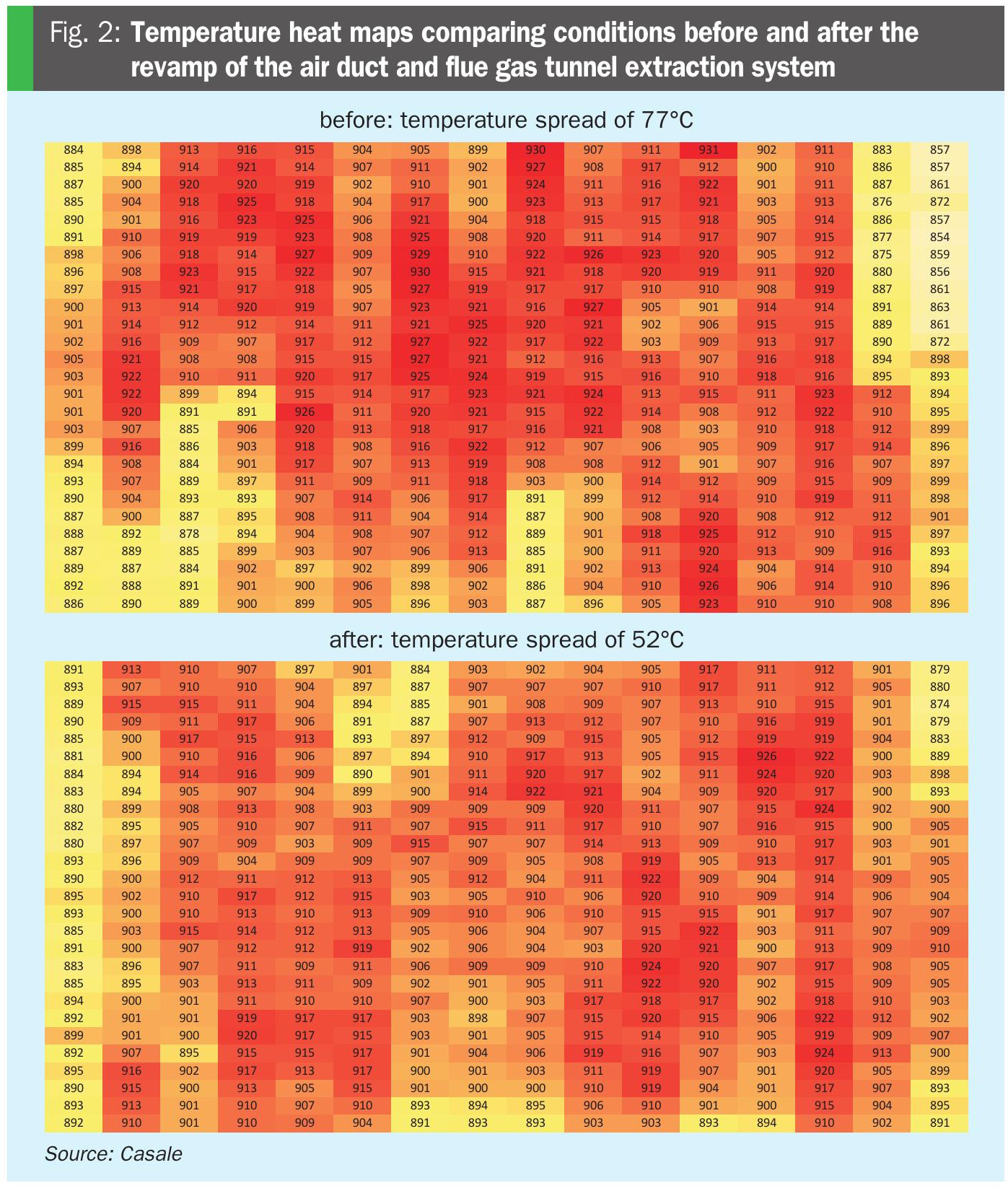

Figure 2 provides an example of how combustion air duct modifications and tuning a traditional flue gas tunnel extraction system have been applied successfully to the revamp of a very big SMR (16 tube rows).

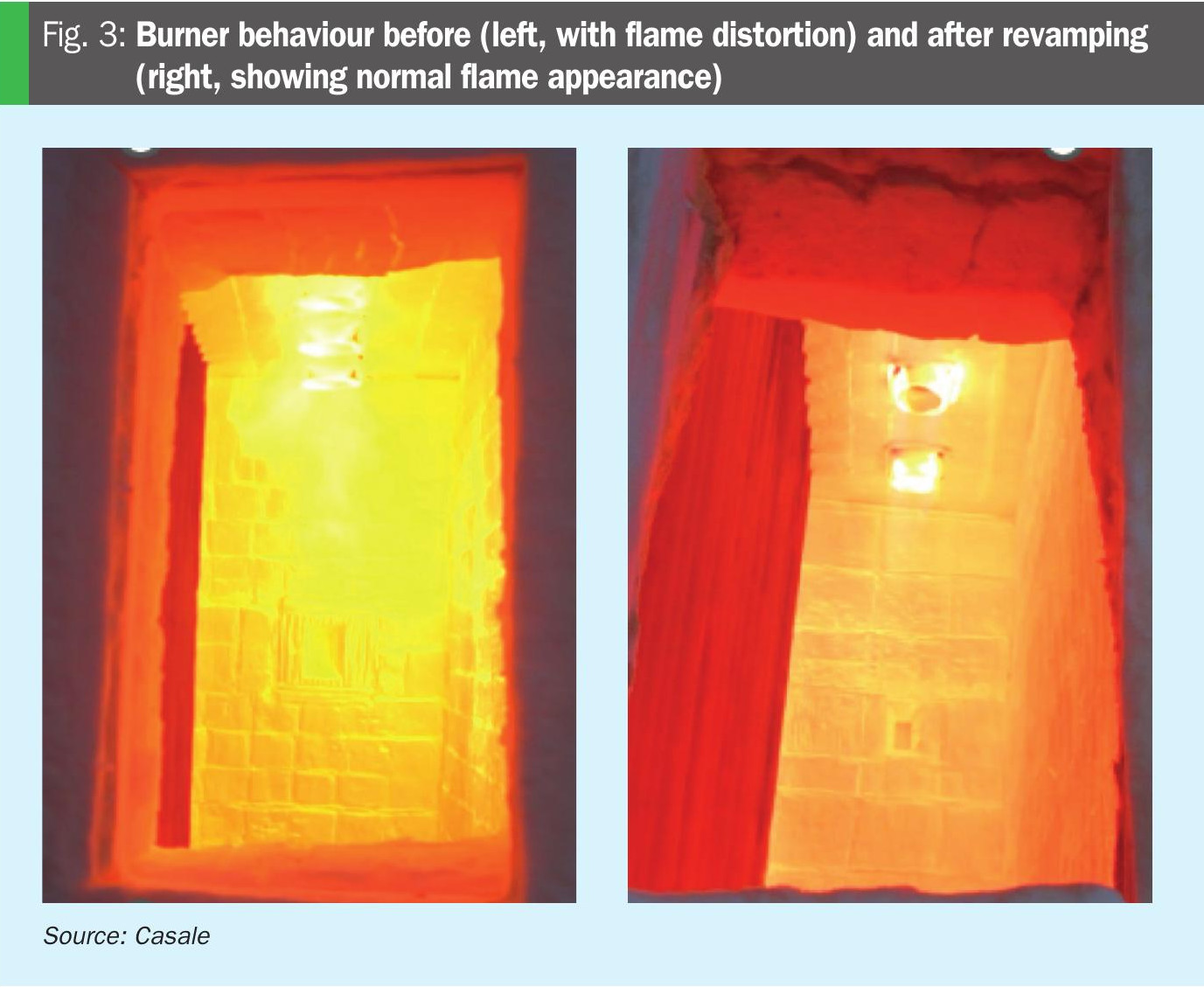

Casale pays special attention to the burners during the revamping process – as these are at the heart of the primary reformer – the aim being to improve combustion efficiency, flame stability, and reduce NOx emissions. These improvements ultimately lead to a more even heat distribution within the reformer furnace (Figure 3). This eliminates damaging hot spots and imbalances in fuel gas flow to the burners, which are often the first signs of unexpected issues.

With a focus on the industry’s future and sustainability improvements, Casale is at the forefront of retrofitting BMS burners and fuel gas systems to enable the primary reformer to switch to using low-carbon fuels, such as hydrogen. The company also has experience in revamping primary reformers with ultra-low-NOx technology burners operating on a fuel stream rich in hydrogen (up to 82% H2 by volume).

This demonstrates Casale’s overall capabilities and experience when it comes to managing the complex challenge of modifying heaters – including the convection section and fans – to operate with a wide range of fuels, these ranging from 100% natural gas to a lighter, hydrogen-rich fuel, as well as the various mixtures in between.

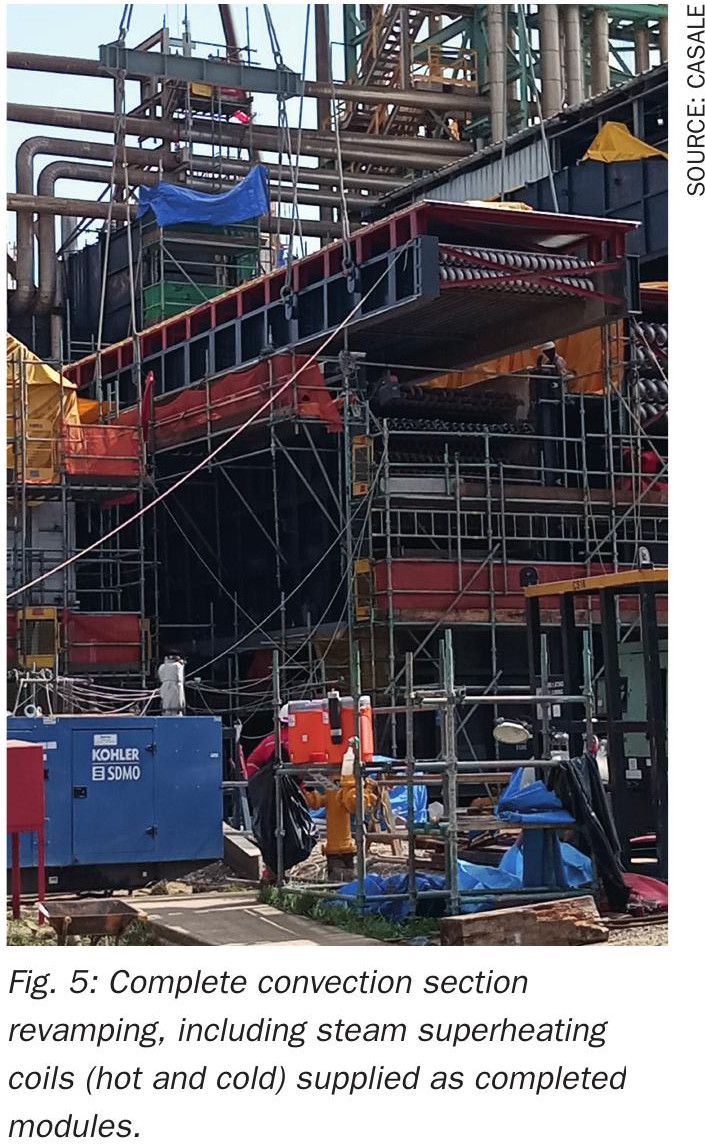

The convection section is the other main part of the primary reformer where Casale has extensive revamping experience (Figures 4-7). This includes tailor-made solutions such as:

• The one-shot pull-in solution which can be provided for any convection section coil to minimise the installation time as much as possible (Figure 4).

• The coil saturator module banks to recover the heat wasted at the reformer stack making available high pressure steam that recovers wasted process condensate (Figure 6).

• APH replacement to the most efficient modern design (many rotary type APHs have been replaced by Casale).

• Conversion of the induced draft primary reformer to the balanced draft configuration (including complete coil module or even complete convection section modules). See Figures 5 & 7.

Revamping other critical ammonia plant sections

Casale has established itself as a global leader in ammonia plant revamping – based on its ability to upgrade existing operations so they remain competitive with new builds in terms of capacity, efficiency, and environmental performance. The company always tailors its revamping approach to the client’s specific objectives, with these ranging from moderate capacity increases to comprehensive upgrades, energy savings, and emission reductions.

Often, the primary goal is to boost production by unlocking latent potential without requiring a complete process redesign. This is achieved by optimising existing equipment while addressing key bottlenecks. For example, by developing a new burner that boosts the performance of the secondary reformer by improving gas distribution and reducing methane slip. Similarly, replacing outdated vertical waste heat boilers downstream of the reformer with double-pipe designs improves both reliability and temperature control.

Shift converters are another area of focus. Casale’s proprietary axial-radial internals have been widely adopted as retrofits into existing vessels, with major pressure drop reductions (from more than 1.2 to below 0.5 kg/cm²) reported in several installations. These internals notably offer superior catalyst protection, reduced pressure drop, and extended catalyst life.

Improving ammonia conversion is the common revamp strategy within the synthesis loop. Where feasible, Casale replaces the converter internals while keeping the existing pressure vessel. Revamping provides an opportunity to improve both reliability and conversion efficiency in older plants where the original converter has been in service for decades – often by installing a larger, more effective reactor.

In many cases, the addition of a second converter downstream of the main converter offers the best return on investment. This increases catalyst volume and boosts per-pass conversion, without major modifications to the circulator or other loop components. Casale’s axial-radial design plays a key role by maintaining low pressure drop and high catalyst utilisation. The addition of a second converter has been applied as a successful strategy in various plants, achieving capacity increases of up to 10% and raising ammonia concentration from 15-20%, while also reducing circulator outlet pressure.

Beyond capacity gains, improving energy efficiency is a major motivation in ammonia revamping. Casale has implemented numerous energy-saving technologies, including revamped CO2 removal systems, natural gas saturation units (Figure 6), syngas drying sections, and advanced low-temperature heat recovery systems. In older plants, these interventions can significantly narrow the performance gap with modern operations.

Casale also supports production stabilisation, especially in regions with hot climates where seasonal peaks in temperature can negatively affect plant performance. This is achieved through targeted enhancements aimed at improving operating margins and reliability. Cooling capacity, for instance, can be increased by leveraging low-grade process heat. Casale offers two proven technologies for improving cooling capacity: lithium bromide-based chilled water units and ammonia absorption refrigeration systems.

Emission reduction is another increasingly important objective – especially in jurisdictions with tightening environmental regulations or where plants are operating near their permit thresholds – and can be addressed on multiple fronts. Lowering carbon intensity requires a focus on minimising methane slip, upgrading CO2 removal, and improving process integration to reduce fuel consumption. While, for reducing non-CO2 emissions, replacing conventional low-pressure condensate strippers with advanced medium-pressure systems is an option. These improvements reduce the plant’s environmental impact and enable compliance with stricter standards.

The cornerstone of Casale’s energy optimisation strategy is the SAVeNG concept. This integrated revamp framework is designed to lower natural gas consumption and overall energy use by streamlining the process, reducing auxiliary steam generation, and adopting high-efficiency electric or gas turbine drivers. The energy savings achieved often make it possible to increase ammonia output without raising feedstock usage.

SAVeNG reflects Casale’s ‘total approach’ to revamping, as it draws on proprietary technologies in both ammonia and urea production, and optimises integration between process units and offsites. It is suitable for any ammonia plant – from 600 t/d to over 2,000 t/d – and any type of urea plant, whether stripping (NH3 or CO2 ) or total recycle, even for multi-train configurations.

Urea production plant upgrades

Urea plant revamps typically emphasise higher throughput and sustainability improvements.

Urea plant energy consumption accounts for only a minor fraction of the entire production cycle, starting from syngas preparation via SMR. Nonetheless, there is still demand for ever more sustainable urea technology, a need that is widely acknowledged nowadays.

Thanks to stringent environmental policies, most urea plants achieve a specific consumption of ammonia very close to the theoretical stoichiometric value – the implication being that the energy consumption associated with ammonia cannot be improved in most cases. On the other hand, most urea plants (including conventional stripping plants) still require a substantial HP/MP steam supply, both as a thermal energy source and to drive machinery. Excluding ammonia, process steam represents the greatest cost variable and is responsible for the largest share of CO2 emissions associated with urea production.

Upgrading the total-/partial-recycle urea process – or other vintage processes – to stripping technology is relatively ‘easy’ and, beneficially, delivers a substantial reduction in the consumption of utilities, especially steam. In particular, total-recycle (TR) processes are very well suited to upgrades to self-stripping technology. Generally, only the high-pressure synthesis section needs upgrading, as the purification sections of the total-recycle and self-stripping processes are very similar.

Consequently, by adding few new high-pressure items, a TR plant can be conveniently converted into a self-stripping plant with a production performance that is close to that of modern greenfield projects. Depending on the actual consumption of the vintage plant, the energy saving can be as high as 0.6 Gcal per tonne of urea.

Increasing the energy efficiency of conventional CO2 – or self- stripping plants isn’t trivial either. Although revamping these (to achieve the same steam consumption as modern stripping plants) is extremely complex, Casale has developed process schemes that reduce process demand for steam by 10-15 %.

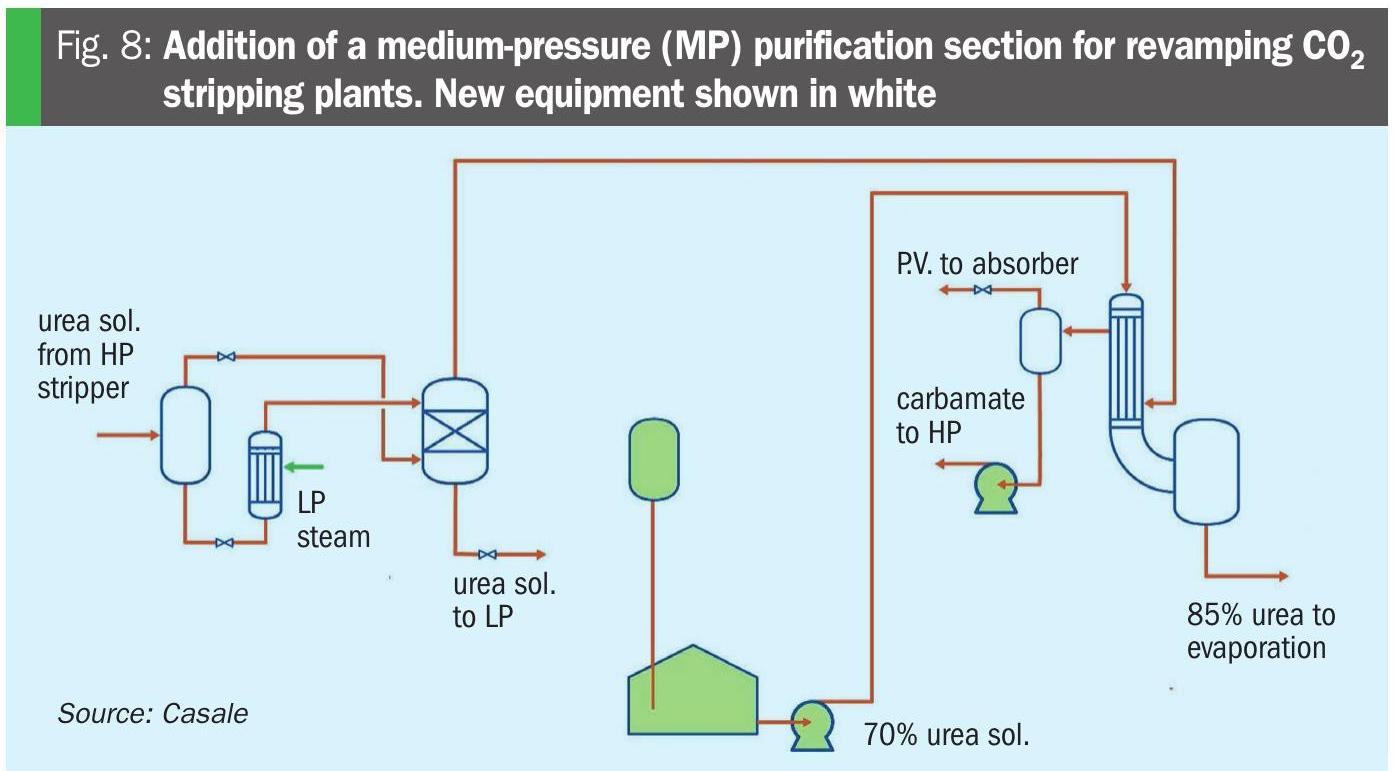

A common strategy is to partially shift carbamate decomposition from the high pressure (HP) stripper to a new medium-pressure (MP) purification stage (Figure 8). For CO2 -stripping plants, the new section operates at about 15 barg while using internally generated low-pressure (LP) steam as heat supply. In this way, the quantity of MP steam saved in the HP stripper is matched by LP steam in the new section.

To avoid compromising the balance of the steam network, a heat-recovery strategy is also implemented. This exploits the heat of condensation of MP vapours generated during carbamate decomposition for urea pre-concentration. The steam saving achieved by the new urea pre-concentration stage is enough to balance out the consumption of the new MP carbamate decomposer and the loss of LP steam production from the HP carbamate condenser (HPCC). In this way, for a conventional CO2 stripping plant, the specific consumption of 23 barg steam (typically from CO2 compressor turbine extraction) can be lowered by about 150 kg/ton urea.

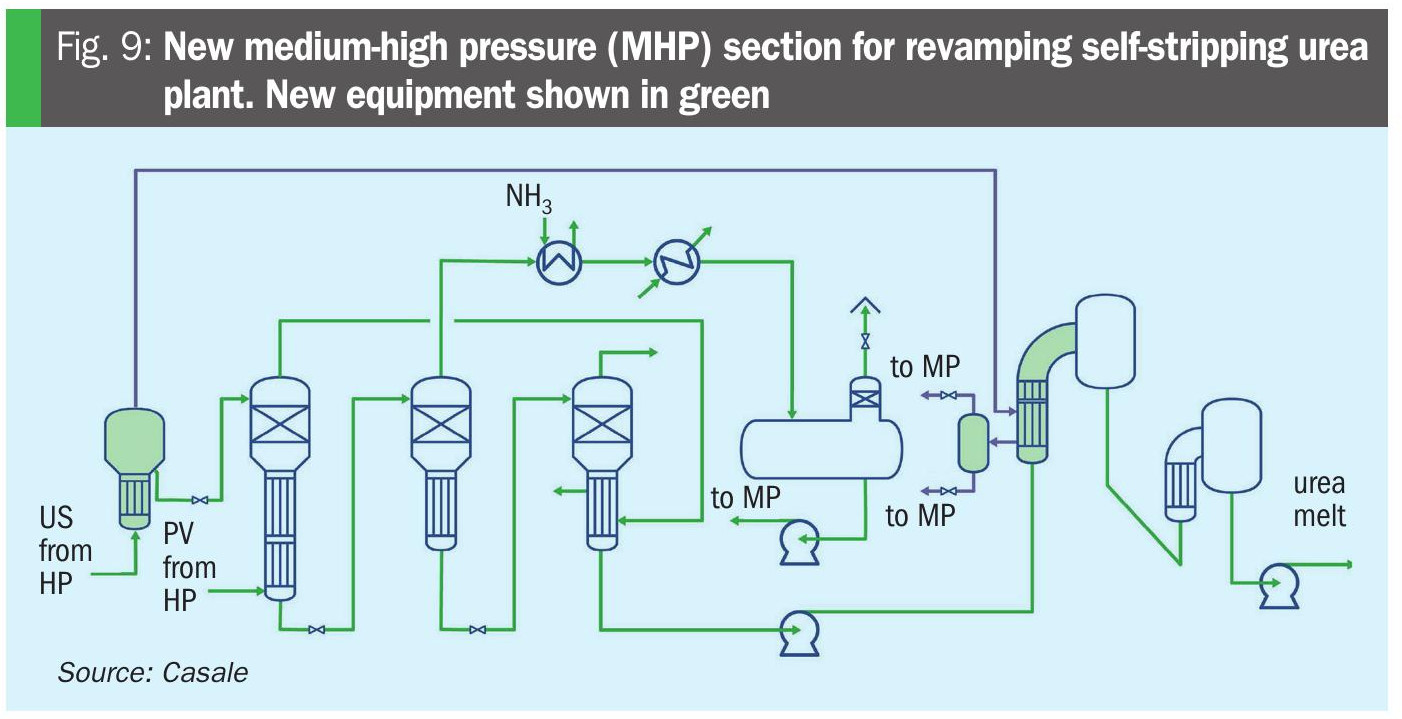

A MP purification stage operating at 18 barg is intrinsic to self-stripping plants, also known as ammonia-stripping plants. Unloading the HP stripper therefore requires a new purification section operating at intermediate pressure, with the range 28-32 barg being optimal. Conveniently, the stream of carbamate vapour generated by this new medium-high pressure (MHP) section (Figure 9) can also be exploited for urea concentration. At this operating pressure, the condensation curve of carbamate vapour allows heat recovery with urea solution at concentrations up to and above 90 wt. %. The saving from not using LP steam for urea concentration counterbalances the new steam consumption by the MHP decomposer (which uses 5.0-5.5 barg steam) and the lower production from the HPCC.

Given that the steam consumption of self-stripping urea plants is already more efficient than their CO2 stripping equivalent, revamping with an MHP section achieves a saving of about 85 kg/t urea.

About the authors

Dario Di Addezio is Fired Heaters Section Manager, Matteo Fumagalli is Urea Technology Manager and Francesco Baratto is Head of Syngas Department at Casale.