Nitrogen+Syngas 397 Sep-Oct 2025

11 September 2025

Finishing technologies shaping tomorrow’s fertilizers

NITROGEN FERTILIZER FINISHING

Finishing technologies shaping tomorrow’s fertilizers

Casale’s high-performance finishing technologies combine flexibility and innovation with seamless integration and sustainability across the nitrogen fertilizer value chain. Gabriele Marcon and Ken Monstrey of Casale present the latest developments in Casale’s comprehensive portfolio of fertilizer finishing technologies and highlight recent projects.

Casale offers a comprehensive suite of finishing technologies for nitrogen-based, complex and phosphate fertilizers. Over decades of active involvement in the fertilizer market, Casale has developed a complete portfolio of finishing technologies through both in-house technology development and strategic acquisitions. As a result, Casale can provide best available technologies for all production stages across the full range of fertilizers. As a licensor, Casale can offer clients a choice of different technologies from its portfolio at various stages of the production process. Additionally, Casale can manage all stages of a project in-house, from project development through engineering, procurement, construction, and both off-site and on-site services. Together, the client and Casale select the technology that best meets the client’s needs, market requirements, and local regulations.

Casale holds a unique market position, offering technologies to produce ammonia, methanol, urea, melamine, nitrates, and phosphates. This unique feature allows for optimal integration among different processes and a tailored approach to any issue involving various areas of the client’s complex. Casale provides a full line of technologies from ammonia to final products.

This article provides an overview of Casale’s finishing technologies for various processes and grades. Granulation production processes for urea, enhanced urea, nitrates, as well as granular ammonium sulphate fertilizer are highlighted.

Urea finishing applications

Fluidised bed granulation

With the acquisition of Green Granulation Technology (GGT), Casale’s portfolio includes urea fluidised bed applications with over 20 references in a wide range of capacities. The optimised fluid bed dynamics (OFBD) have proven to be innovative and industry changing. The focus on energy efficiency, that has been directing the urea synthesis process developments during the last decades, was brought to the finishing process by the introduction of the OFBD. Casale’s R&D capabilities have further refined the fluidised bed technology, resulting in a broader range of design options by adapting proven design features from other Casale technologies and introducing new, innovative developments. Therefore, depending on the client’s requirements, the focus of a new fluidised bed process for urea fertilizer production can be based on capex or opex drivers or a perfect mix of features. These innovations have led to higher design flexibility and the ability to produce special grades such as automotive urea and cattle feed grade urea.

As an alternative, or as an additional feature, the fluidised bed process can be designed to produce DEF-grade urea. The granulation unit must operate without the addition of a granulation additive (zero formaldehyde or others), and the biuret content must be kept low enough to enable remelting without exceeding the maximum allowed biuret content of AdBlue. Therefore, the feed concentration to the granulator must be free of contaminants, such as formaldehyde, typically used as a granulation additive for fertilizer grade, and the urea feed concentration must be relatively low to guarantee low biuret content. These factors result in a feed composition likely to lead to poor spraying conditions in the granulation process, high dust production, and short run lengths. Casale’s expertise in the urea field can provide solutions characterised by a urea feed concentration with very low biuret content that matches with the requirements for DEF-grade granulation, including a limited distance between the synthesis and the granulation buildings. Alternatively, a dedicated evaporation section within the granulation battery limits, operating under deep vacuum and low temperature conditions, can be foreseen. Both enable sending a feedstock to the granulator that falls within the parameters for water content, guaranteeing a high-quality final product.

In the absence of a granulation additive and at low biuret content, the granulation process depends entirely on optimised conditions in the subsequent spraying zones in the fluidised bed. Casale relies on the performance of specially designed hydraulic spray nozzles that are self-atomising without high atomisation air requirements. The Mark II and newly developed Mark III hydraulic spray nozzles produce a very homogeneous spray pattern with a narrow size distribution of droplets at low atomisation air pressure. The atomisation air merely blows the produced droplets deep into the fluidised bed layer, creating a maximum spray zone height, increasing efficiency, and ensuring a continuous flow of fresh particles towards the spray zones. The OFBD principles adopted in every Casale (and GGT) unit ensure smooth and predictable movement in the bed, providing an optimum alternation of accretion and drying phases during the granulation process. Unlike a bubbling bed granulator, the Casale OFBD operates at a low bed level, reducing the pressure drop over the system and thus reducing the unit’s power consumption.

Recent technological innovations focusing on minimising the pressure drop over the product coolers and exhaust air scrubbers have further reduced the specific power consumption. Urea, as a commodity, still accounts for the largest market share of fertilizer applications worldwide. Therefore, Casale continues to focus on further development, deeper research, and finding marginal gains to keep the technology at the top of the innovation pyramid. In 2025, the first application of the new and improved Mark III liquid nozzle with higher operational reliability (fewer splits) and higher operational flexibility will be implemented.

Enhanced urea finishing applications

Urea + AS in the double granulator

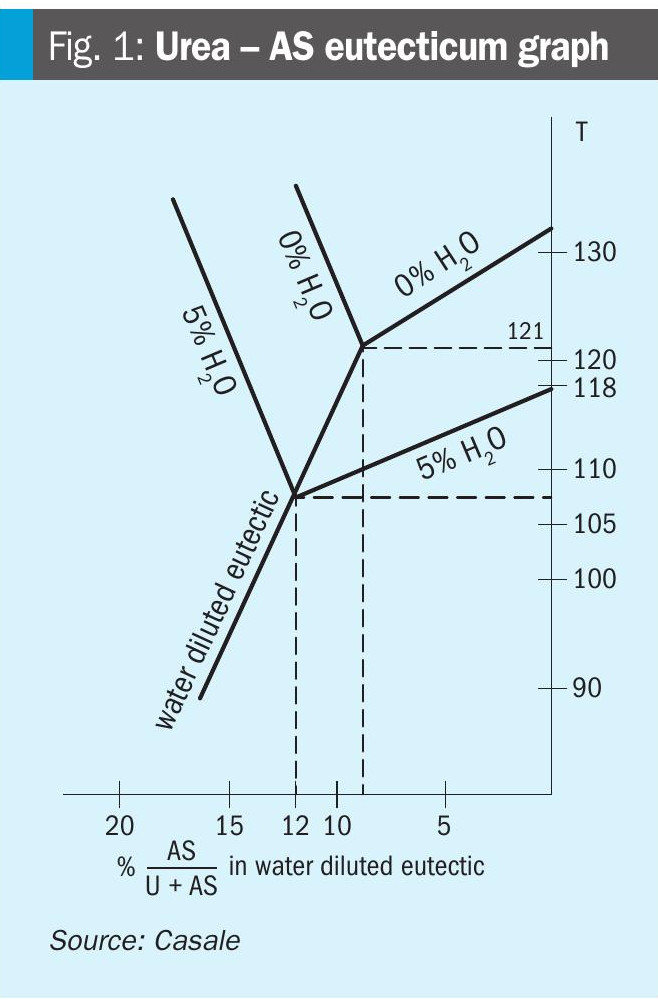

Meanwhile, the fertilizer market is shifting towards products that offer more than just a nitrogen source. Adding a sulphur source to urea is a straightforward step to increase efficiency and application field of general fertilizers. Ammonium sulphate (AS) is widely available, even as a by-product of other production processes, such as the ammonia abatement system in the scrubbing section, and it is a low-cost sulphur source. The main challenge when solidifying a mixture of urea and AS is the presence of a eutectic point, where the crystallisation temperature of the mixture drops by approximately 10°C (see Fig. 1). Under such conditions, the temperature in the fluidised bed must be reduced by 10°C to allow proper crystallisation. Lowering the bed temperature would normally lead to poor water evaporation inside the bed and poor drying of the granules, resulting in off-spec product.

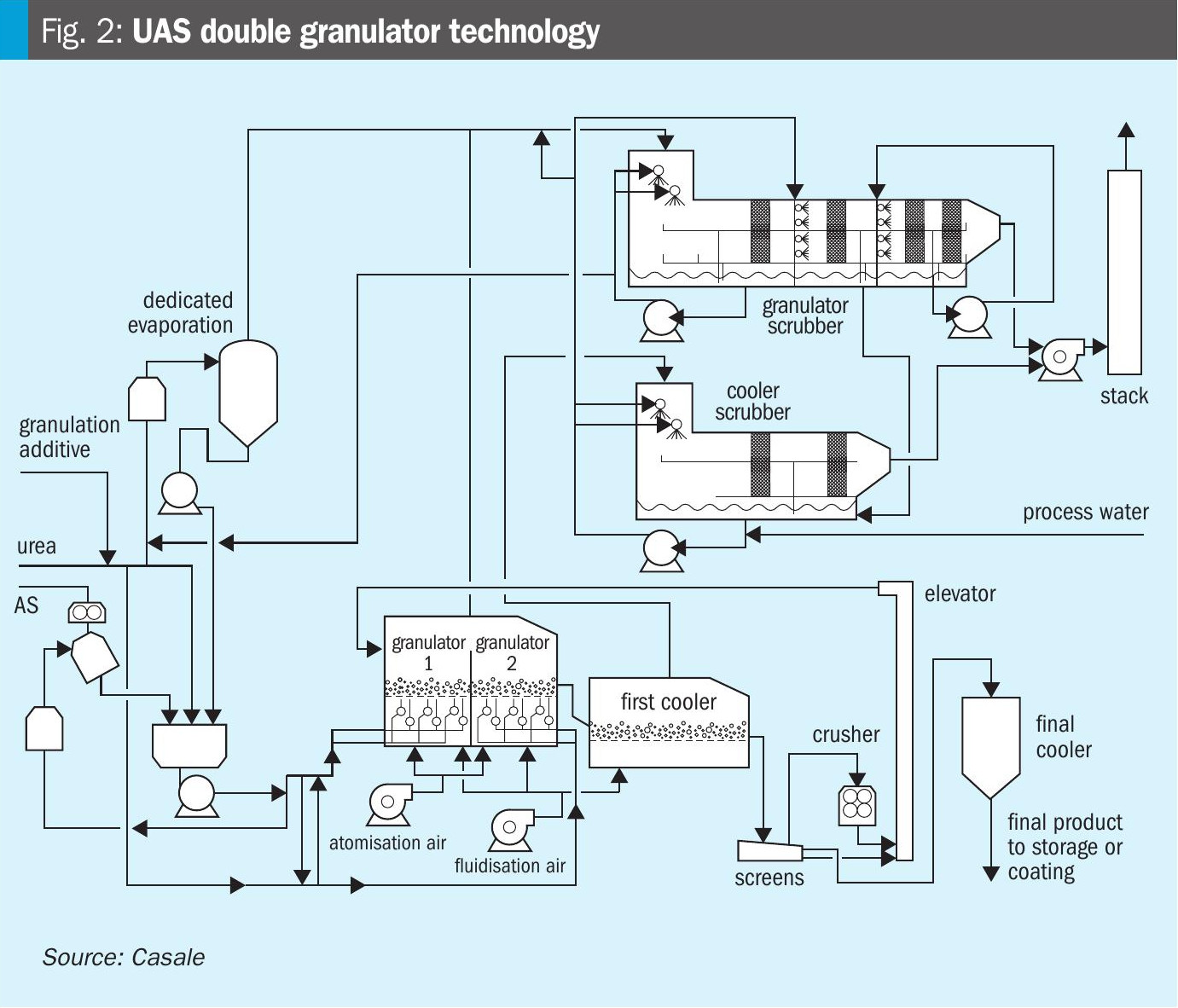

Casale has therefore developed and patented the “double granulator” principle, a specific fluidised bed production process for UAS that offers the flexibility to produce standard urea granules or any grade of UAS from 0 to 25% ammonium sulphate content without any loss of quality features and without the need to reduce the bed temperature at any feed composition. The “double granulator” principle allows feeding different melt compositions to different granulator sections, avoiding the eutectic mixture of urea and AS and enabling the production of any UAS composition under optimal granulation conditions, ensuring top-quality product. This flexibility also allows clients to continue production even if the AS supply is compromised or reduced.

AS contents higher than 10 wt-% in the urea feed concentration (>96%) are no longer soluble and lead to slurry rather than solution spraying inside the granulator. Therefore, the liquid sprayers must be specially designed to handle the crystals. The scrubbing section can handle a large quantity of crystals and inerts in the airstream without upsetting the process. A dedicated evaporation section ensures that no AS is recycled to the upstream synthesis plant and is designed to prevent AS crystallisation in the evaporation heater. It also offers the advantage of adjusting the final water content in the UAS feed, influencing the crystallisation point and providing a second tool for fine-tuning the system to guarantee optimal conditions in the granulator (Fig. 2).

The first-of-a-kind double granulator plant for UAS production has been commissioned in the first quarter of 2025. The 1,200 t/d unit will be able to operate on both urea and UAS, with AS contents ranging from 0-20 wt-%. The commissioning on urea went smoothly. The AS storage and preparation section are being installed and AS addition is to be expected in Q3 of 2025.

Enhanced urea application in the pre-granulator

Intense farming over long periods depletes the soil at high rates. Available farmlands are being stripped of valuable elements that crops need to grow sustainably. Standard general fertilizers add macronutrients such as nitrogen, phosphate, potassium, sulphur, etc., to the field, which plants need for growth. Growing crops also absorb micronutrients such as iron, boron, copper, zinc, etc. These elements are essential for vegetation, even in small amounts. Each harvest reduces the content of minerals in the soil. Casale offers technology to produce nitrogen-based fertilizers containing micronutrients in various compositions for wide applications or tailor-made ends.

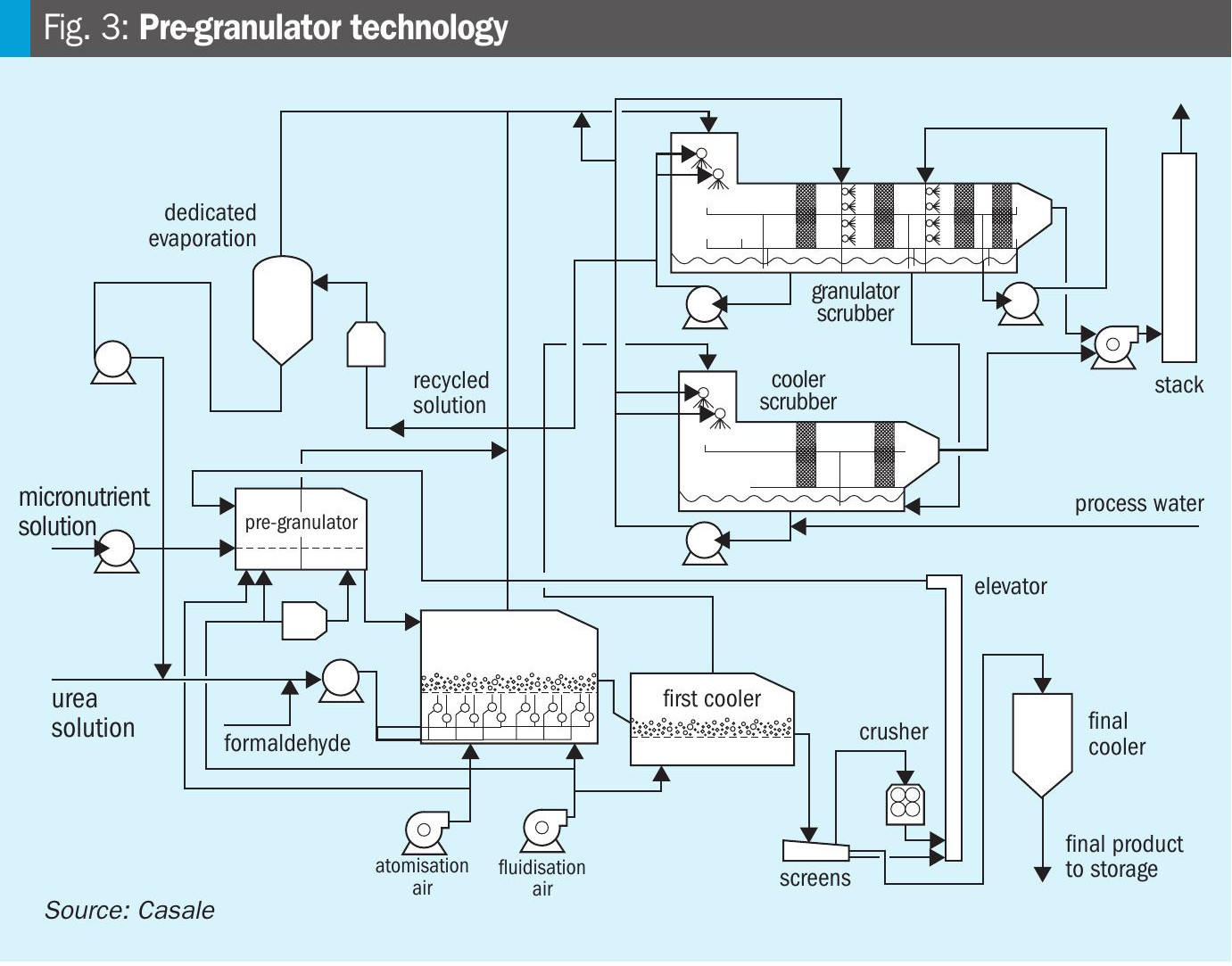

The pre-granulator technology (Fig. 3) adds micronutrients or other additives to the core of the granule rather than coating the granule. This is achieved by spraying small amounts of additive on the seeds produced by crushing oversize granules or adding specific seeds to the pre-granulator and covering them with a protective layer to shield them from heat impact in the further process. Adding specific elements to the granule’s core greatly improves the additive’s efficiency and eliminates premature wash-off in the field. The pre-granulator allows adding the additive under mild bed temperature conditions, preserving the additive’s integrity.

Nitrates finishing applications

Fluidised bed granulation

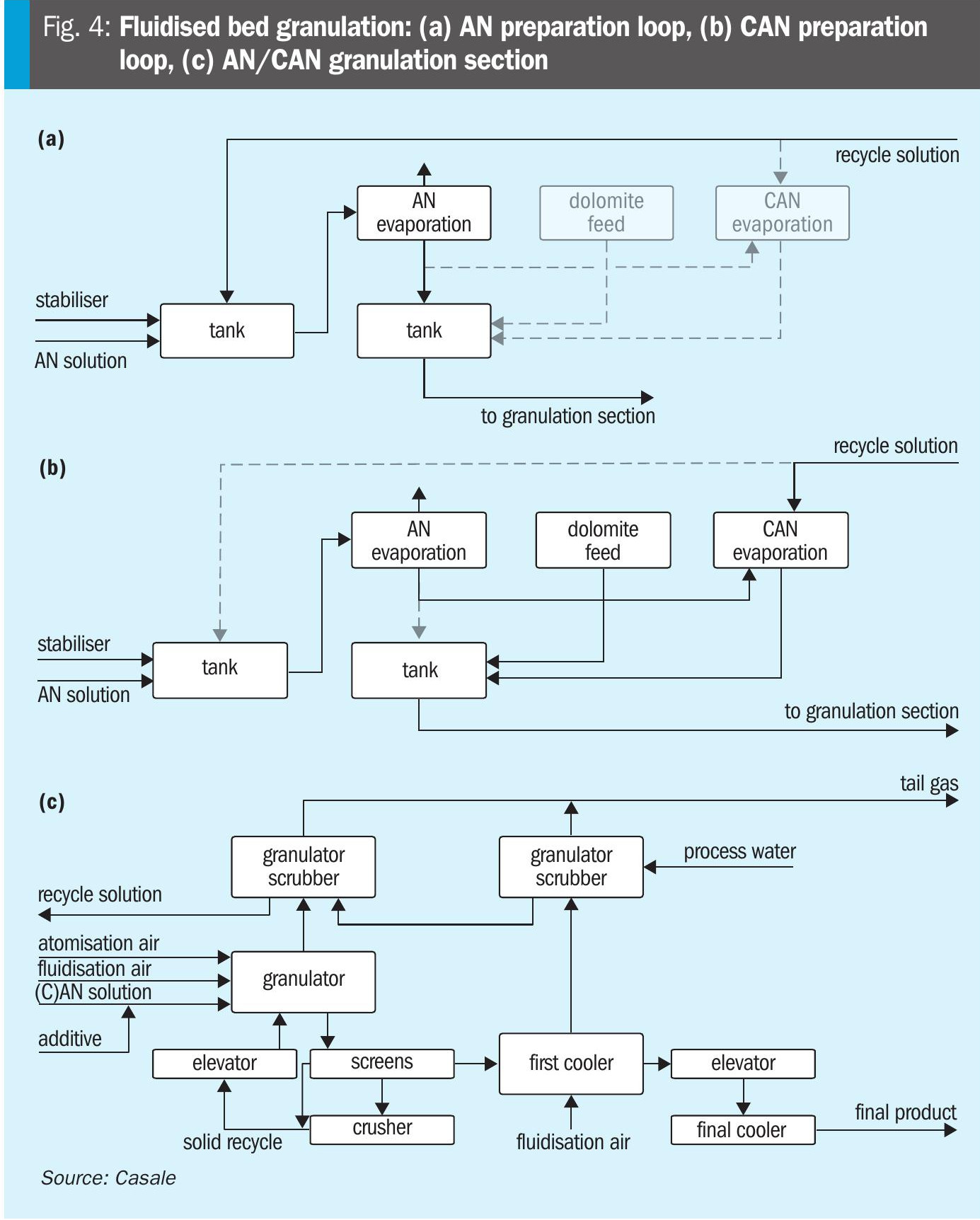

With the acquisition of Green Granulation Technology, Casale has also acquired a reference in AN/CAN fluidised bed granulation. The 1,015 t/d AN – 1,300 t/d CAN plant was constructed and commissioned during the COVID-19 pandemic and has been in operation since. This unit features the unique combination of AN and CAN in a fluid-bed-based plant and can be operated with different granulation additives and stabilisers. Hydraulic liquid spray nozzles ensure prime quality product features and low dust production during the granulation process. The step-by-step cooling is designed to preserve granule integrity throughout the process and prevent hazardous temperature cycling during production, which may compromise product density and eventually crumble the granules, making them vulnerable to atmospheric pickup or organic contamination. The different crystal transition points of AN and the different influences of product stabilisers on these transition points are accounted for in the process design. Anti-backmixing features and flexible cooling ensure smooth crystallisation of the melt or slurry and controlled cooling to appropriate storage temperature.

The process consists of two melt preparation loops that may or may not be integrated depending on the end product. When producing AN grade, the AN loop provides the melt directly to the granulation section without passing through the CAN loop. When producing CAN grades, the AN melt prepared in the AN loop is sent through the CAN loop and brought to appropriate concentrations before being sent to the granulation section. Switching from AN to CAN can be done on the run. For a switch from CAN grades to AN, the system needs to be rinsed and cleaned, with the collected wash liquid stored in a shutdown tank for future CAN runs.

Temperatures in the preparation section are kept moderate to ensure safety while handling hot AN melt. The process stays safely away from the 180°C upper limit, with a safety trip initiation to ensure safe operation.

The fluid bed granulation plant (Fig. 4) is usually preferred when large capacity is required (usually above 1,500-2,000 t/d) and it can be designed for capacities up to 5,000 t/d in a single train configuration.

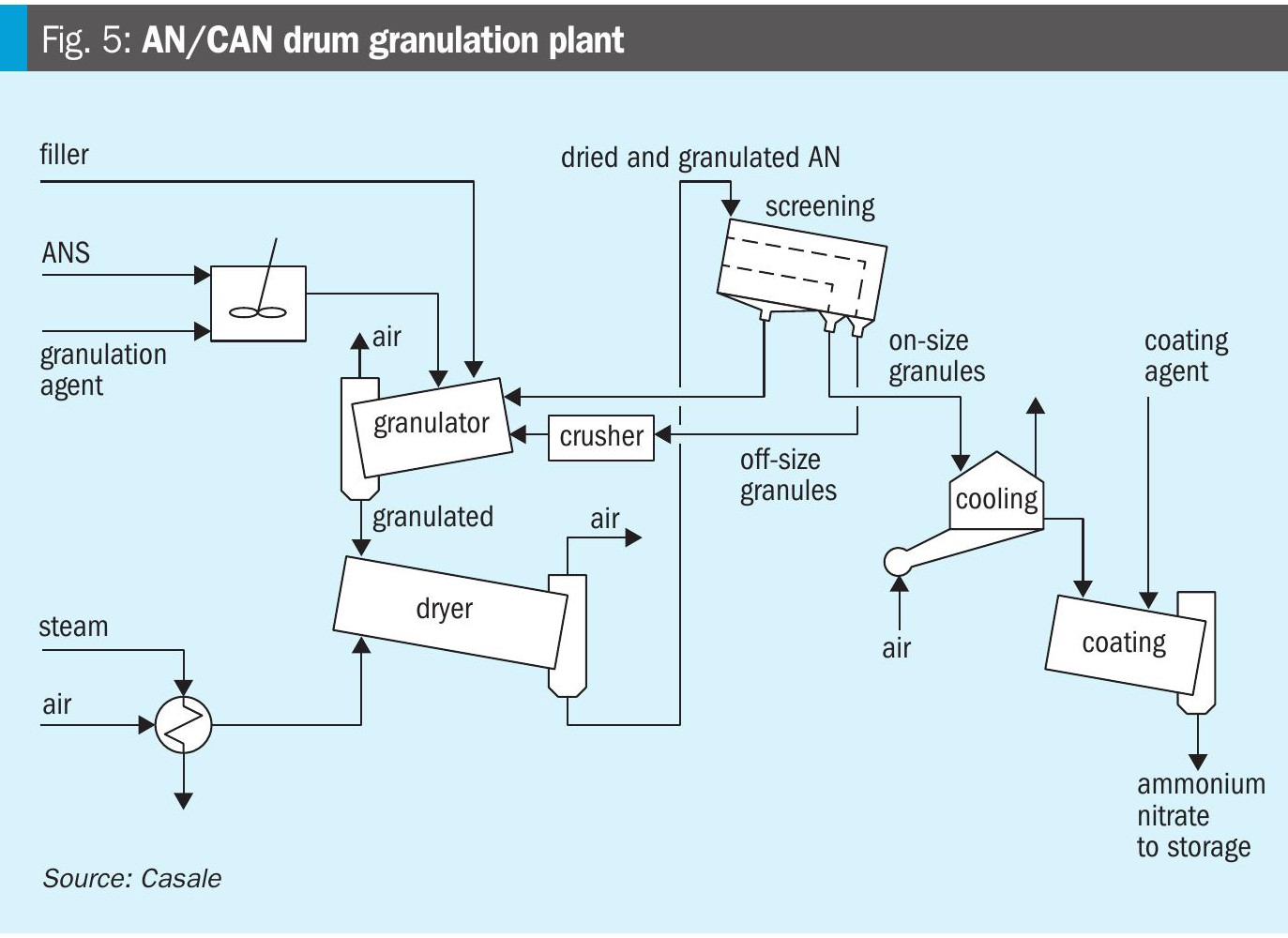

Drum granulation

In addition to fluidised bed technology, Casale also offers a flexible drum granulation loop technology for production of high-quality granules with uniform size and durability, well-suited for modern wide spreading on agricultural fields. The drum technology (Fig. 5) is used in over 50 plants worldwide and is very versatile, capable of producing a wide range of different AN-based fertilizers like ammonium nitrate fertilizer (HDAN), calcium ammonium nitrate (CAN), ammonium nitrate sulphate (ANS), etc., in the same plant. The resulting granules are well-suited for modern, wide spreading on agricultural fields. In view of the above characteristics, drum granulation is preferred when high product versatility and lower plant capacity are requested. Typically, drum granulation can achieve a capacity up to about 2,500 t/d in a single line.

Together with ammonium nitrate, various raw materials such as dolomite, limestone, calcium sulphate, ammonium sulphate, etc., can be added to obtain different types of AN-based fertilizers. This allows easy granulation of 33.5% N ammonium nitrate, 26-27% N ammonium nitrate (such as CAN), ammonium nitrate sulphate (ANS), and 34.7% ammonium nitrate for technical uses.

Additionally, nitric or sulphuric acid can be used in the acid scrubbing section to drastically reduce ammonia emissions to the atmosphere. Finally, a granulation agent and coating agent(s) can be used to improve granulation efficiency and guarantee optimal final product quality.

The plant is designed to achieve the lowest recycling ratio, depending on product grade, selected raw materials, and the ratio between solid and liquid phases.

The plant comprises the following major items:

- a rotary drum granulator, in which ANS is sprayed over a moving bed of recycled particles consisting of fines, dust, coarse ground grains, part of recycled final products, filler (e.g. limestone or dolomite) and solid raw material, if required (e.g. ammonium sulphate or calcium sulphate).

- a rotary dryer with hot air to decrease the residual moisture in the final product.

- a screen to separate the on-size product from the small and the oversize one. The latter are crushed, mixed with the former and fed back to the granulator together with a portion of the final product to keep a constant recycled flowrate.

- a fluidised bed cooler for the on-size product. A coating agent is added in a dedicated drum, to prevent caking. The product is then sent to storage.

- a dedusting and scrubbing system, which recovers ammonia and dust from all the gaseous effluents, to prevent pollution and minimise losses.

Villeta project

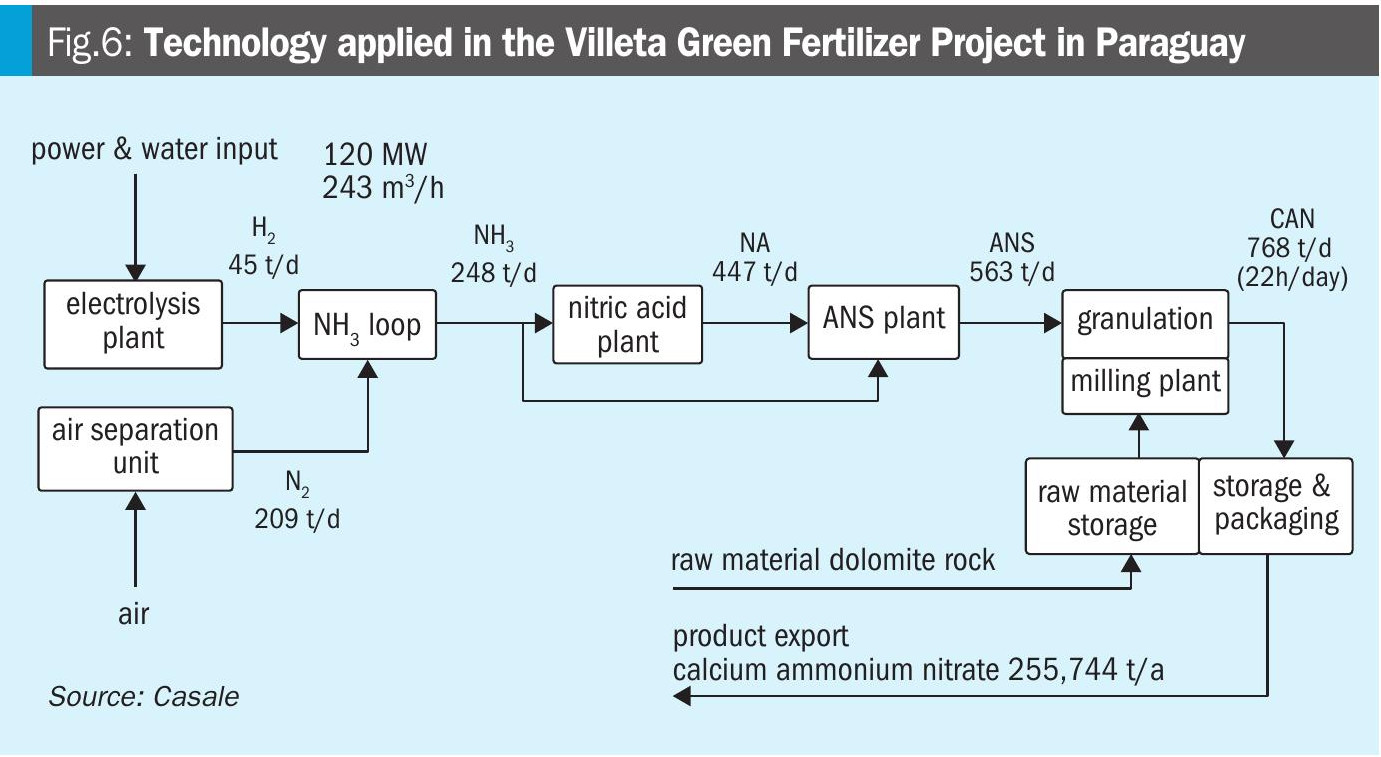

The Casale drum granulation technology has been recently selected and applied in the Villeta Green Fertilizer Project in Paraguay (Fig. 6).

Located 35 km from Asunción along the Paraguay River, the Villeta project utilises Paraguay’s abundance of hydropower to establish a world-scale production facility for green fertilizers. This project aims to meet domestic and international fertilizer demands while significantly reducing greenhouse gas emissions, exemplifying a model for sustainable industrial development.

Key features include:

• a 145 MW power purchase agreement with ANDE;

• advanced production facilities capable of producing over 250,000 t/a of calcium ammonium nitrate (CAN);

• zero-carbon production processes are powered entirely by hydropower.

The Villeta project stands out for its reliance on advanced technologies, ensuring high efficiency and sustainability.

Drum granulation technology further applications

In addition to AN-based fertilizers, the drum granulation loop technology is applied by Casale for both complex fertilizers (i.e. NPK) and the production of granular AS fertilizer. This concept allows the possibility to design a single granulation loop able to produce a very wide range of different fertilizers completing all the needs requested from the market.

The Casale multi-granulation plant is a single drum granulation plant equipped with all necessary equipment for AN-based fertilizers, NPK complex fertilizers and granular AS fertilizers. It includes dual pipe reactor technology (GPR+DPR), an AS pre-neutraliser, an ANS concentration section, and a common scrubbing system that can work with nitric acid, sulphuric acid or phosphoric acid.

Ammonium sulphate drum granulation

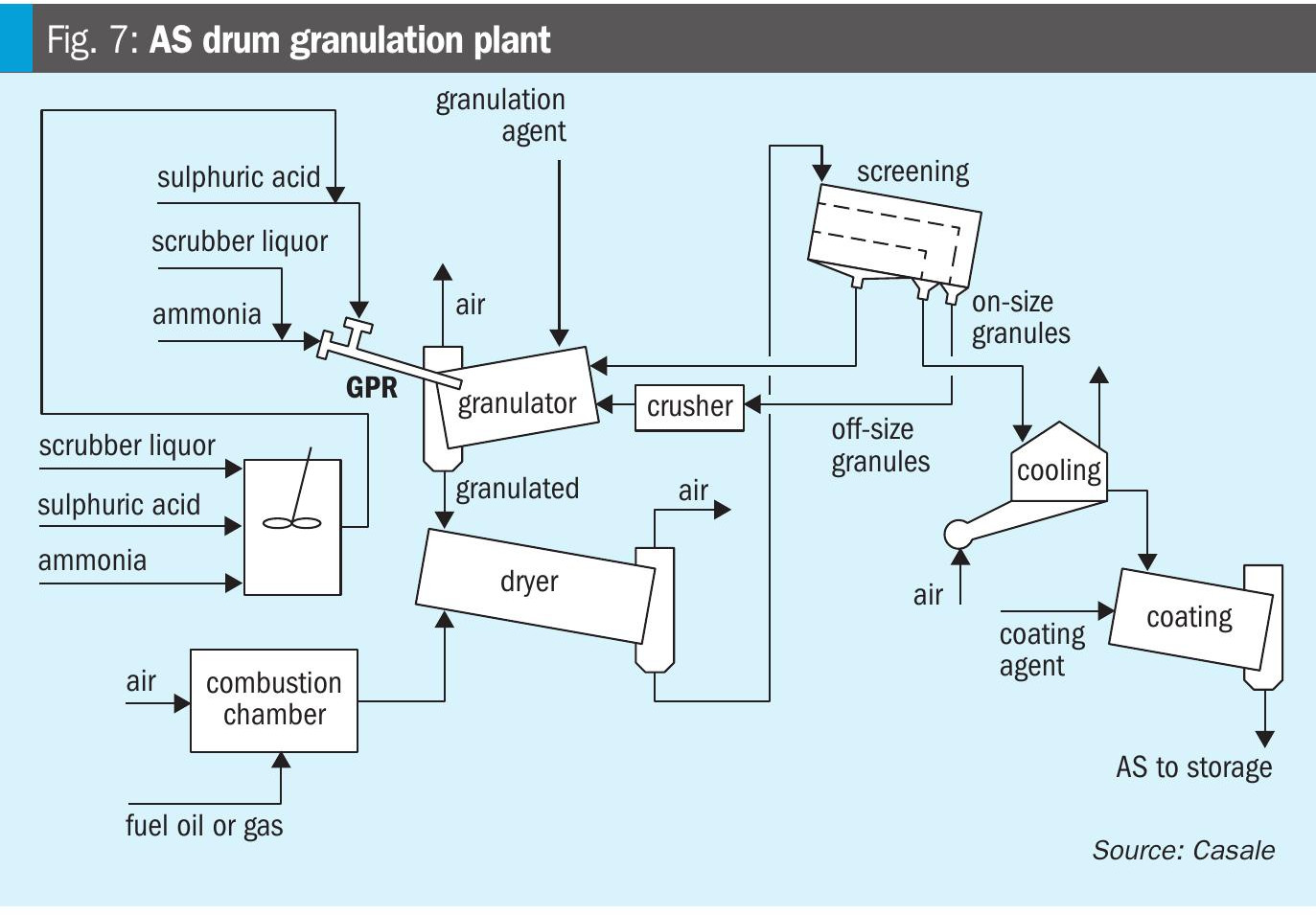

Casale’s drum granulation technology suited for the direct production of fertilizer grade granular ammonium sulphate is illustrated in Fig. 7.

AS is produced by the direct reaction between sulphuric acid and ammonia that takes place in the pre-neutraliser and the granulator pipe reactor.

Sulphuric acid is also added in the acid scrubbing section to minimise ammonia emissions to the atmosphere. Finally, a granulation agent and coating agent(s) are used to improve granulation efficiency and guarantee optimal final product quality.

The plant configuration and H2SO4/ NH3 split between the pre-neutraliser and the granulator pipe reactor is designed to achieve the lowest recycle ratio, minimising the equipment dimensions and therefore the plant investment cost.

The plant comprises the following major items:

- pre-neutraliser + pipe reactor installed in the granulator drum: ammonium sulphate is produced by the chemical reaction between ammonia and sulphuric acid. The reaction takes place in two different pieces of equipment. The first reactor is an agitated vessel, called the pre-neutraliser (PN), and the second reactor is the pipe reactor installed in the granulator drum (GPR). The PN is fed by a portion of ammonia and sulphuric acid; the product is fed to the GPR together with additional raw materials. Ammonia is, thus, split between the PN and GPR. The remaining stoichiometric amount of ammonia is injected directly into the drum granulator through the ammonia sparger. The water, mainly the recycled scrubbing liquor, is mostly fed to the PN to maintain good fluidity of the ammonium sulphate slurry. The balance of the water is fed to the GPR.

- rotary drum granulator, where AS slurry from the GPR is sprayed over a moving bed of recycled particles consisting of fines, dust, coarse ground grains, part of recycled final products.

- rotary dryer fed with hot air to decrease and control the residual moisture in the final product.

- screens to separate the on-size product from small and oversize product. The latter are crushed, mixed with the former and fed back to the granulator together with a portion of the final product to keep a constant recycled flowrate.

- fluidised bed cooler for the on-size product. A coating agent is added in a dedicated drum, to prevent caking. The product is then sent to storage.

- dedusting and scrubbing system, where ammonia and dust from all the gaseous effluents are recovered, to prevent pollution and minimise losses.

Turkmenistan project

Casale drum granulation technology for granular AS production has been recently selected and applied for Turkmenhimiya, the state-owned chemical company of Turkmenistan, and will be built in Turkmenabat.

Once completed, the new complex will produce:

- 100,000 t/a of ammonium sulphate (AS)

- 350,000 t/a of granular single superphosphate (SSP).