Fertilizer International 528 Sep-Oct 2025

11 September 2025

Award-winning Sulvaris – Canada’s technology innovator

FERTILIZER TECHNOLOGY SHOWCASE

Award-winning Sulvaris – Canada’s technology innovator

At a time when nutrient use efficiency, sustainability, and profitability are paramount, Sulvaris is aiming to transform low-value by-products into high-performance, field-ready premium nutrient products – enabled by scalable and innovative technology. Mark Howell, Head of Agronomy & Product Development at Sulvaris, introduces the company’s technology portfolio.

Sulvaris was founded in Calgary, Alberta, Canada, with the vision of building bridges between industries by adding value to by-products that would otherwise be considered waste or a liability. Alberta, for example, is a region that generates large tonnages of elemental sulphur from its sizable oil and gas sector. Sulphur in this form can supply valuable agricultural end-markets globally – although it does require careful processing to become usable as a crop input.

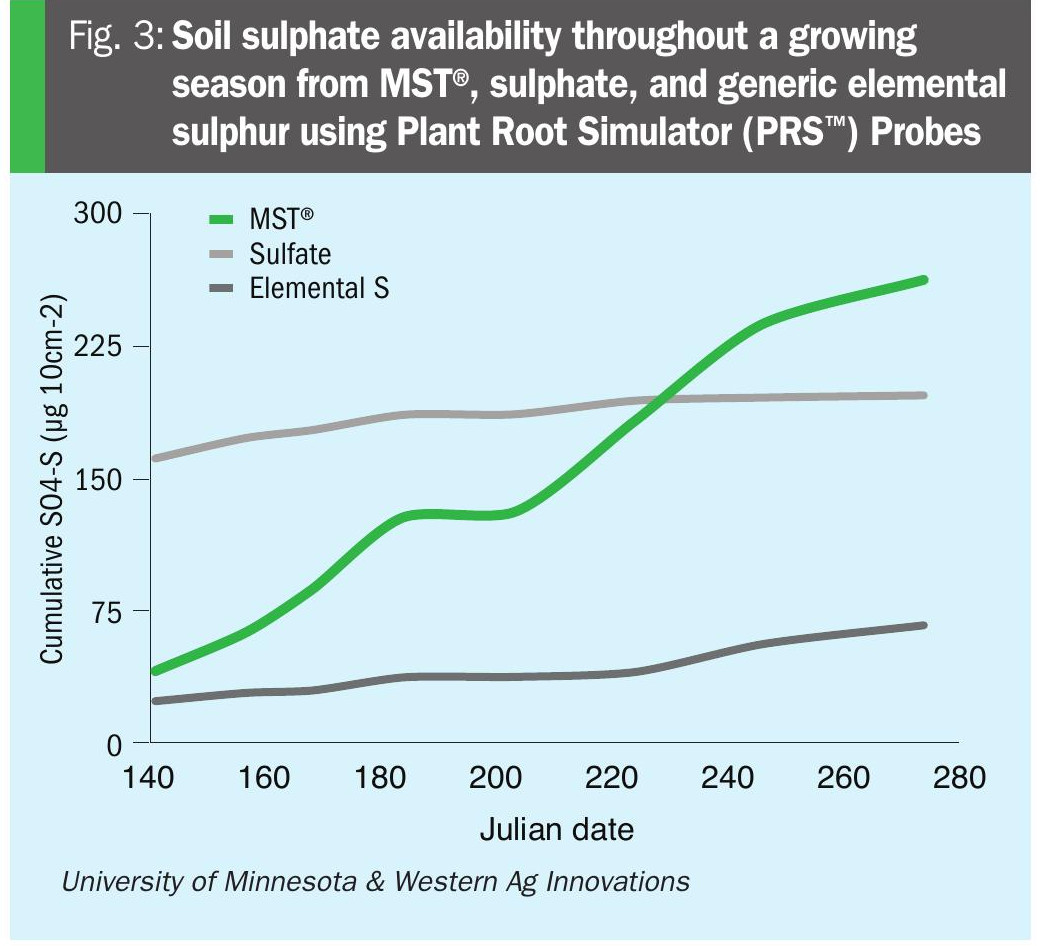

Crops are, in fact, unable to directly take up elemental sulphur. Instead, it needs to be converted into sulphate (oxidised) by soil microbes before plants can absorb it as a nutrient. The good news is that the oxidation of sulphur into plant-available sulphate can be accelerated by using finer particles to dramatically increase the surface area accessible to soil microbes. Indeed, the exposed surface area of elemental sulphur increases exponentially as particle size decreases.

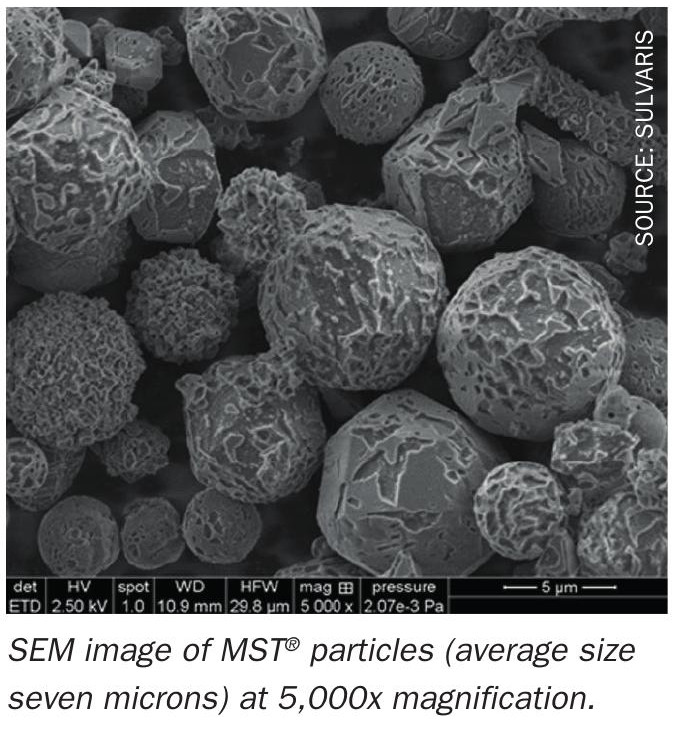

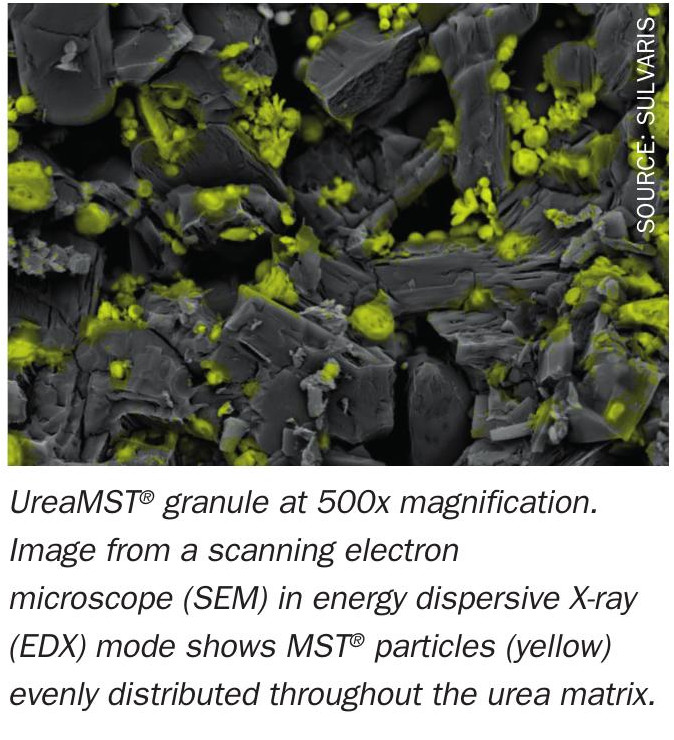

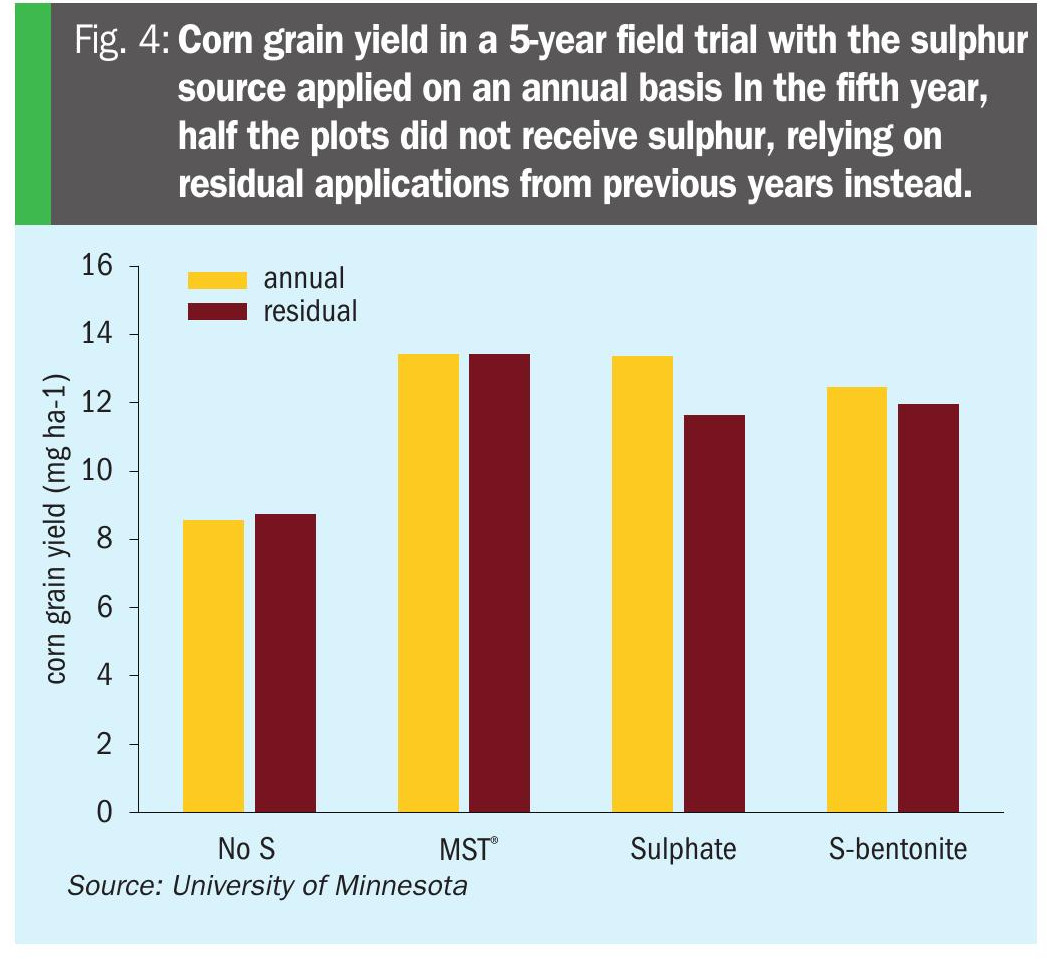

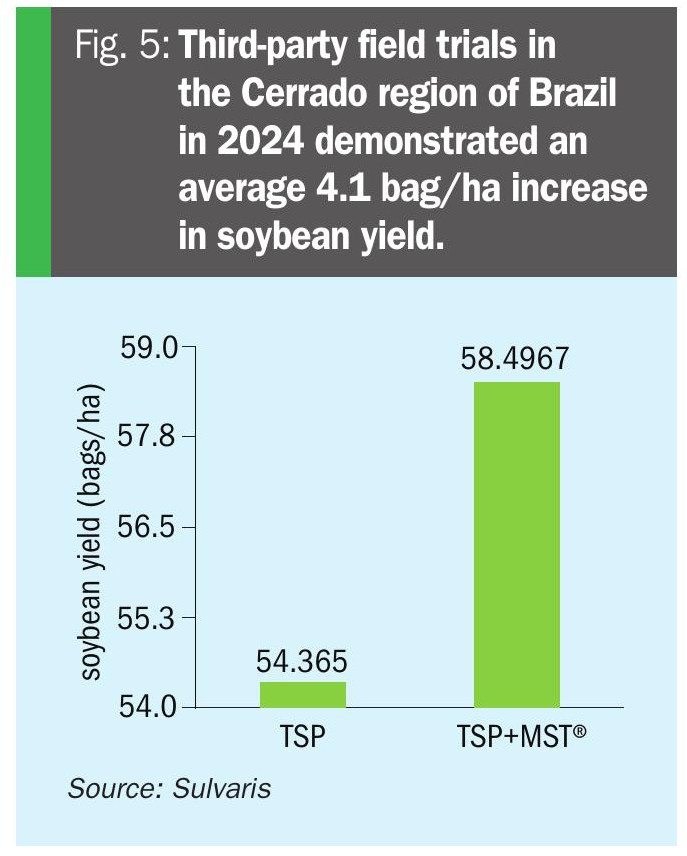

Sulvaris has developed Micronized Sulfur Technology (MST® ) for the crop nutrition market. This patented process engineers sulphur particles to a small and consistent size of seven microns (95% range 1-12 microns) – the smallest scale that is economically feasible in commercial fertilizers today (see black and white photo). Unlike standard elemental sulphur that oxidises very slowly, or sulphate sources that are susceptible to leaching, MST® strikes a balance by oxidising steadily as soils warm, maintaining a supply of sulphur in the root zone throughout the growing season.

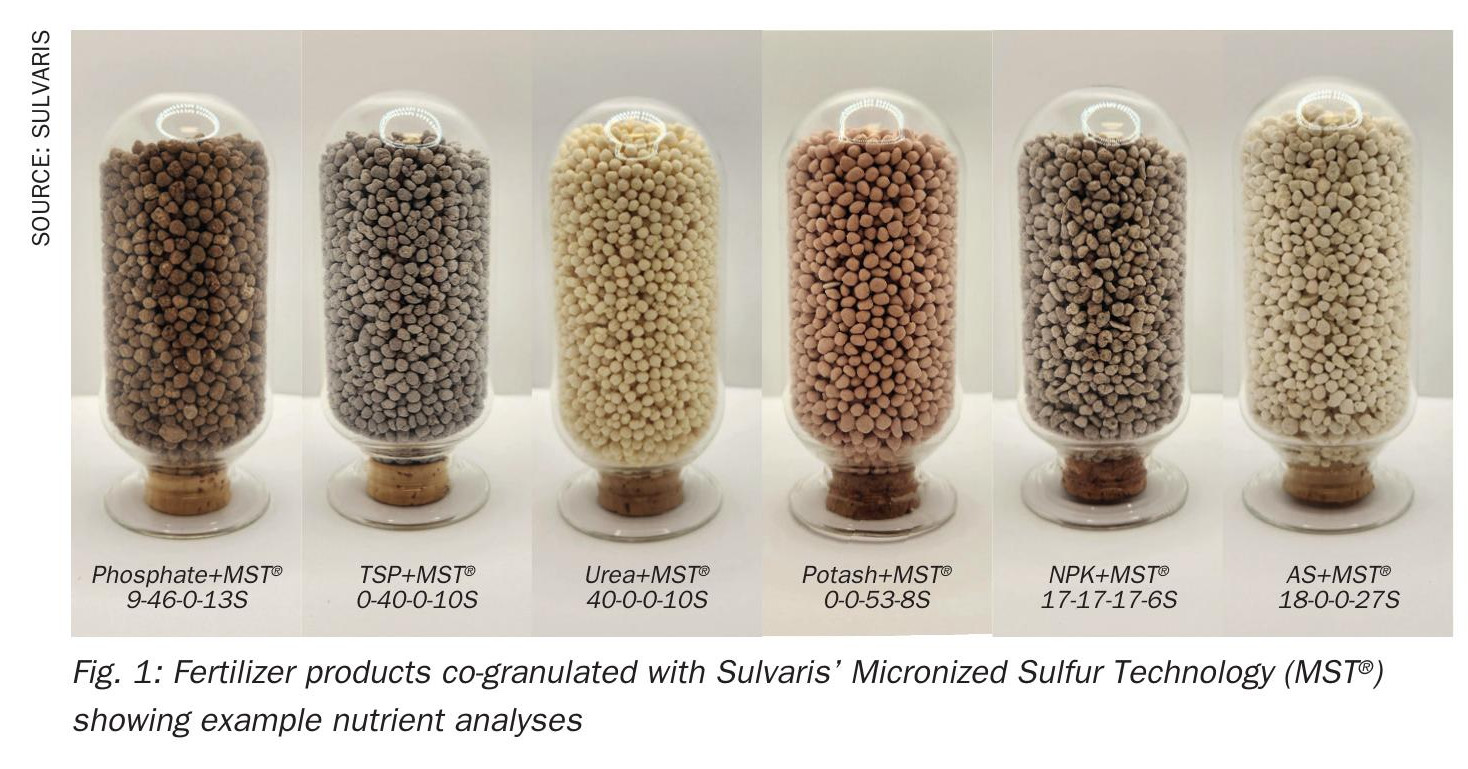

In a key point of differentiation from other technologies, Sulvaris offers MST® to producers and distributors as an integrated production option for a full portfolio of nitrogen, phosphorus, potassium, and compound NPK fertilizers (Figure 1). Furthermore, Sulvaris has developed a liquid MST® offering for fertilizer applications. Liquid MST® also functions as an amendment for high soil pH and sodic soils. It is also an economic and effective foliar-applied fungicide.

Sulvaris technologies allow fertilizer producers and distributors to capture premium margin opportunities by enhancing agronomic value. Instead of selling commodity products, licensees can integrate Sulvaris technology into their existing production processes – boosting nutrient delivery, improving product handling, and delivering higher-return products to distributors and growers.

Sulvaris’ principal technology offerings include: the award-winning Micronized Sulfur Technology (MST®), Carbon Control Technology (CCT®), and its latest Sulvaris Advanced Granulation Engine (SAGE™) platform.

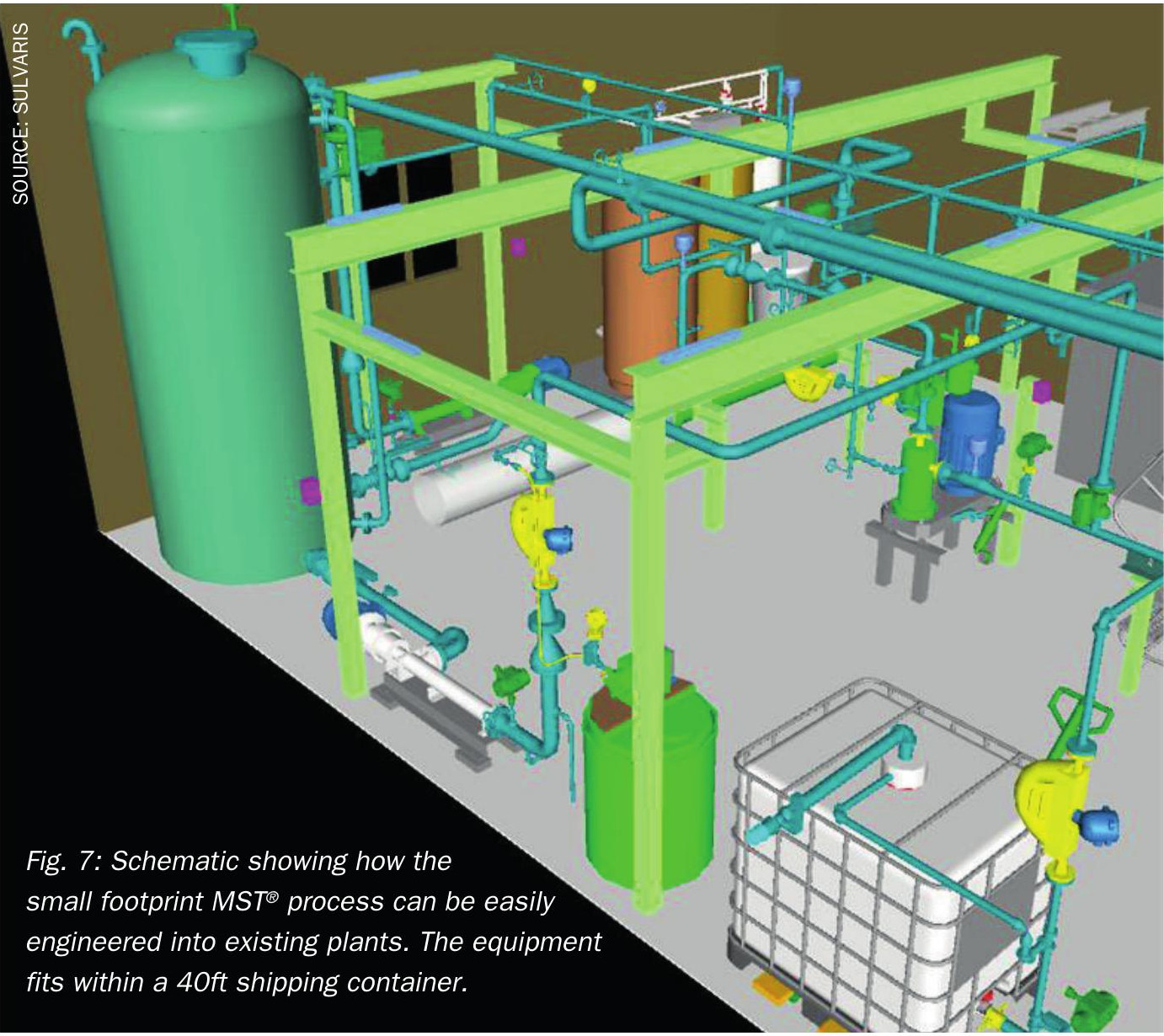

Licensing lets industry players enter sulphur markets with upgraded products without the capital burden of developing their own technology, while gaining the added certainty provided by a de-risked commercialised product. The ‘bolt-on’ nature of these technologies means very low capex investments and minimal production disruption, plus a small equipment footprint – with a process that is highly scalable and designed to meet the needs of a variety of clientele including producers and distributors.

Agronomic and environmental dividends

Sulphur (S) is essential for amino acid and protein formation, chlorophyll synthesis, and enzymatic processes. Yet global agriculture is increasingly confronted with sulphur deficiency. Factors such as cleaner air and declining SO2 emissions, widespread use of high-analysis fertilizers lacking S, more intensive cropping systems, and losses to leaching have all led to a decline in sulphur supply.

Globally, CRU estimates that only about half of the sulphur required by crops is currently supplied by fertilizers, with the largest deficits in India, Sub-Saharan Africa, and the CIS. Even in high input regions such as East and South Asia, sulphur deficits remain at 46 % and 62 %, respectively.

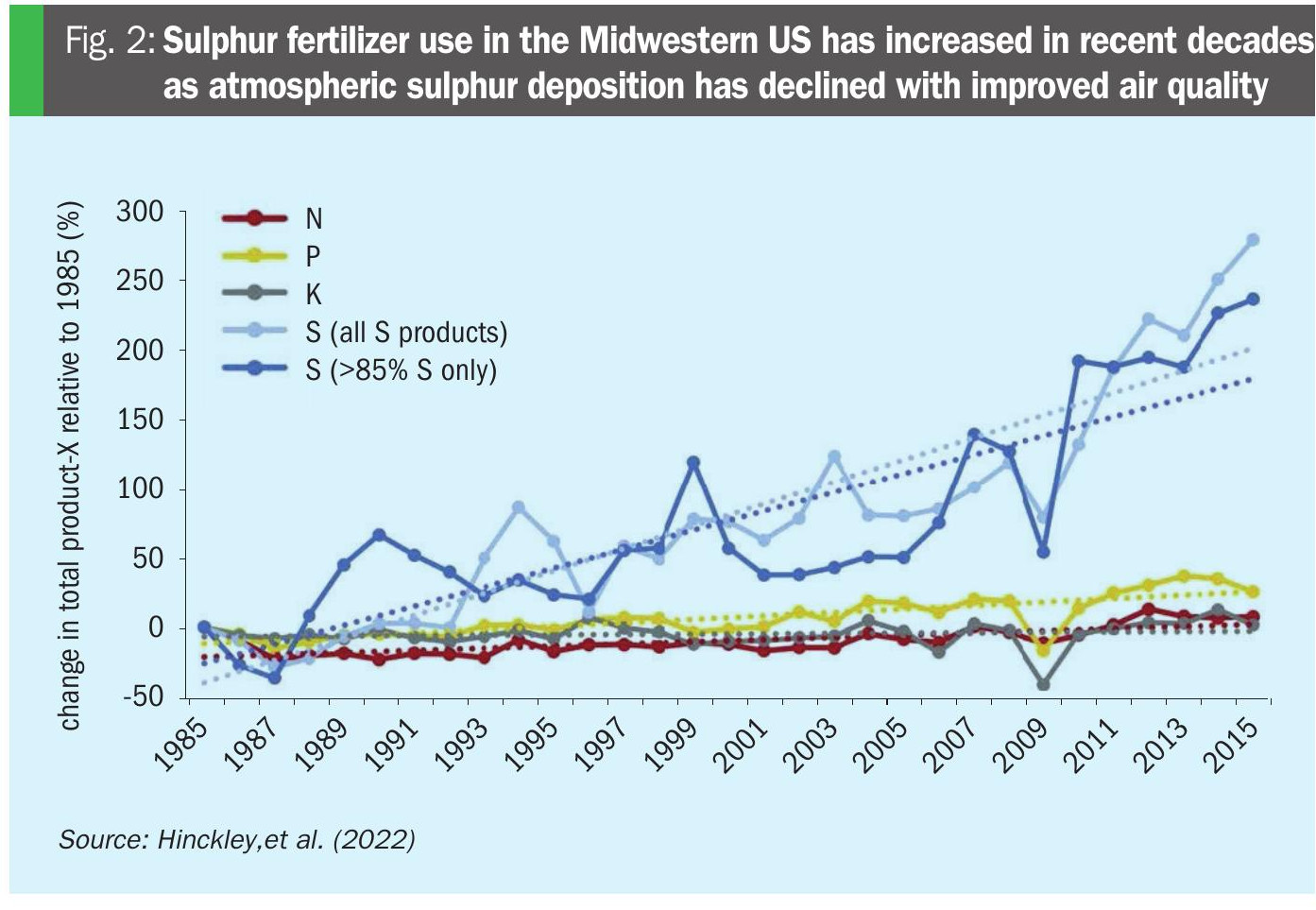

In particular, declining atmospheric deposition from industry has removed what used to be a ‘free’ sulphur source for agriculture. To counterbalance this decline, sulphur fertilizer applications in North America have increased annually by 7.7% since 1985, versus the much lower 1-2% growth rate in nitrogen, phosphorous, and potassium applications (Figure 2).

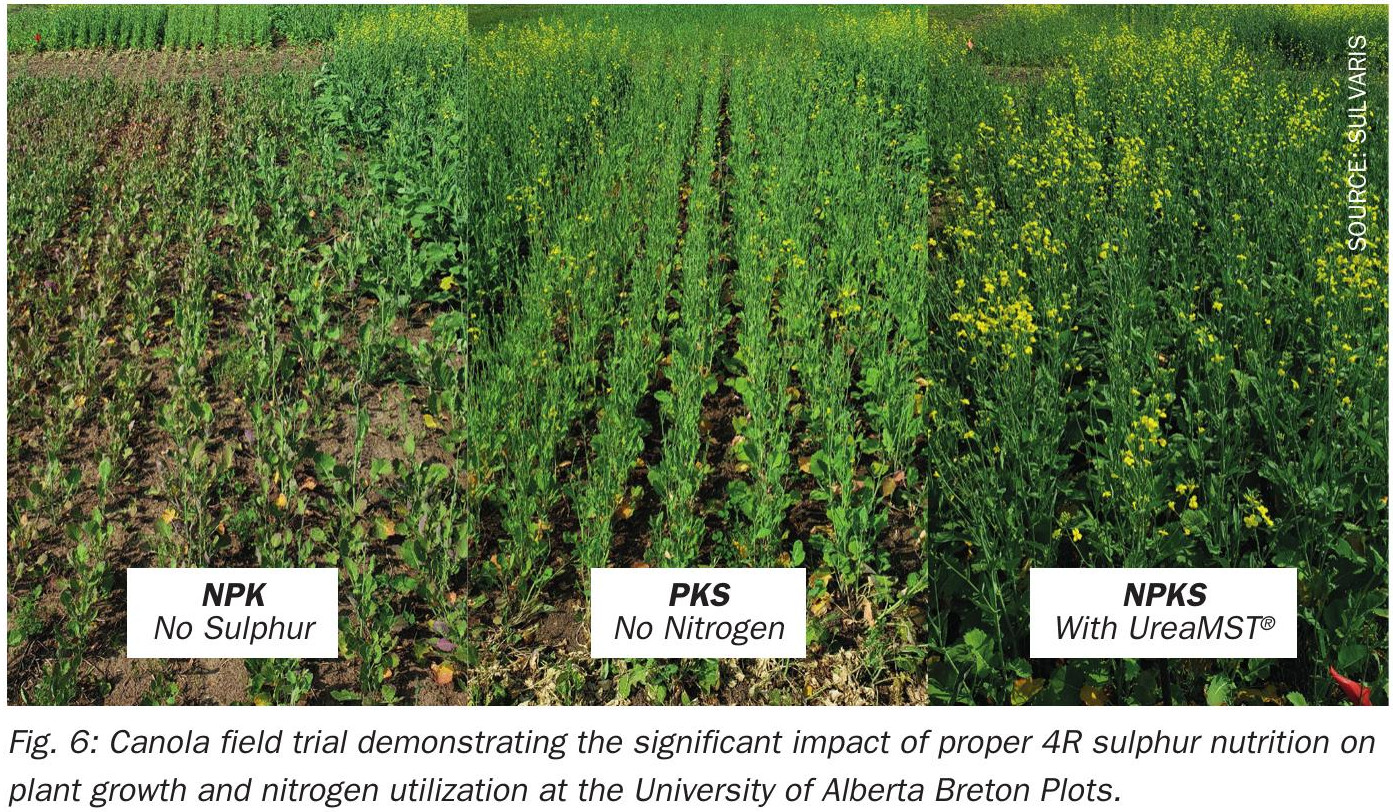

When sulphur nutrition is insufficient, crops will not attain their full yield potential and, consequently, will not maximise uptake of other applied nutrients like nitrogen. This exacerbates inefficient nutrient use with negative environmental consequences, such as leaching losses to waterways and greenhouse gas emissions.

Perhaps one of the most striking examples of this is for canola (Figure 6) – where sulphur is a cornerstone nutrient and necessary to unlock protein synthesis. Consequently, a lack of sulphur can lead to poor nutrient uptake and toxic accumulations of nitrates in the crop. Long-term plots have also demonstrated that – in addition to lower yields – insufficient sulphur lowers soil organic matter accumulation and increases the potential for greenhouse gas emissions.

Milestone moment – the IFA Science Innovation Award

In April 2025, Sulvaris captured global attention by winning the inaugural International Fertilizer Association (IFA) Science Innovation Award in the Novel Fertilizers category. Selected from 22 global submissions, the award recognised MST® as a groundbreaking fertilizer technology that is a novel, practical, scalable and sustainable. Satish Iyer (co-founder) and Mark Howell (Head of Agronomy) accepted the award on behalf of Sulvaris at IFA’s Cultivating Tomorrow conference in Barcelona.

This international accolade recognises MST® as a leading process option globally for producers wishing to address sulphur deficiencies.

As Alzbeta Klein, IFA’s CEO, highlighted: “[Sulvaris] stood out to our judging panel because of their ability to find a robust technological solution to both sulphur deficits and losses in agricultural systems, leveraging scientific expertise with accompanying evidence of implementation and impact.”

This comes at a time where IFA and The Sulphur Institute (TSI) are recognising sulphur as the ‘fourth plant macronutrient’ alongside N, P, and K, having recently launched an initiative to assess sulphur deficiencies and applications globally. Sulvaris, alongside other key industry players and academia, will contribute data and expertise to a global crop nutrient database. This will help identify areas where crop quality and yields can be improved with better nutrient management including sulphur applications.

Fertilizer producers, faced with margin pressures and regulatory demands, need scalable technologies that provide product differentiation and improve nutrient use efficiency. MST® offers a simple, efficient process that integrates into existing production lines with minimal downtime, low capex, and a compact footprint (Figure 7) – making it a practical and accessible ‘bolt-on’ option for both fertilizer producers and distributors.

These valuable characteristics have been further validated, de-risked and commercialised in Nutrien’s Smart Nutrition MAP+MST® product, currently available in the North American market. Overall, the MST® process is highly scalable and, to meet the needs of a variety of clientele, is suitable for producers looking to augment commodity fertilizer production and generate premium products at volumes from 15,000 tonnes to several million tonnes.

Building on the IFA award and the recognition it provides, Sulvaris continues to add to its intellectual property (IP) portfolio and enhance its global relevance as a technology provider. This notably includes recent patent submissions for MST® integration and CCT™ production.

Looking ahead: scaling impact with innovation

Sulvaris is building a series of innovations to meet emerging tech and sustainability imperatives in the fertilizer industry:

• Micronized Sulfur Technology (MST®) addresses sulphur deficiency with precision and season-long efficacy with upgraded premium fertilizers.

• Carbon Control Technology (CCT™), by sequestering carbon and improving nutrient use, embeds sustainability properties within the structure of fertilizers.

• The Sulvaris Advanced Granulation Engine (SAGE™) offers an adaptable manufacturing system for premium products that provides balanced crop nutrition to a distributed market.

Sulvaris, through its licensing business model, has shown that providing licensees with transformative fertilizer technologies delivers high-margin potential. With MST®, the company offers the market a novel, highly functional product that seamlessly integrates into existing production systems and delivers proven yield, handling, and environmental advantages.

Now, with CCT™ and SAGE™, Sulvaris is setting the stage for a new generation of fertilizer technologies. For producers and distributors looking to migrate beyond standard commodity fertilizer offerings, this is a gateway into enhanced-efficiency, sustainable products that meet regional agronomic demands and ESG goals alike.

CCT™ – a circular economy solution

While MST® unlocks the sulphur market and provides an entry for fertilizer producers, Sulvaris is also advancing its Carbon Control Technology (CCT™), a platform that elevates the capacity to deliver multi-nutrient, sustainable fertilizers in a carbon-rich matrix. CCT™ is a patented innovation that integrates and enriches biomass by-products with crop nutrients to form a stable carbon structure.

CCT™ provides a circular economy solution by valorising biomass or crop residue waste streams as feedstocks. Generated by our Sulvaris CCT reactors, these products have demonstrated enhanced nutrient delivery with slow-release nitrogen, yield improvements and, importantly, reduced greenhouse gas emissions, while simultaneously contributing to soil organic matter. Beneficially, this turns a liability (waste biomass) into a valuable agronomic input.

SAGE™ – moving beyond MST® and CCT™

The Sulvaris Advanced Granulation Engine (SAGE™) is a new production system designed to deliver enhanced-efficiency MST® fertilizers with low capex, fast cycle time, and scalability. SAGE™ enables producers and distributors to access Sulvaris technologies in a de-risked platform designed to create high-value products, while also maintaining their standard commodity output.

It offers the capability to produce co-granulated MST®-enhanced NPK granules with:

• Flexible granulometric control

• Uniform nutrient distribution

• Better performance over traditional blends

• Improved product handling

• An ability to develop market specific formulations adapted to regional needs.