Fertilizer International 527 Jul-Aug 2025

7 July 2025

Crop nutrient product innovation

Fertiberia, OCP Nutricrops, GoudenKorrel and Omnia provide an update on the latest offerings in their product portfolios.

FERTIBERIA

Impact Zero – decarbonisation starts now

The agri-food industry stands at a pivotal moment, facing urgent challenges such as climate change and food security. In this context, Fertiberia has made a strong commitment to contribute to the decarbonisation of the sector through innovation. As a result of this commitment, Impact Zero was born – a lower-carbon solution to crop nutrition that, says the company, represents a paradigm shift in fertilizer production.

Impact Zero is the world’s first fertilizer range to replace natural gas with green hydrogen in the ammonia synthesis process, while also incorporating cutting-edge technologies that enhance nutrient efficiency. The result is products that significantly reduce the greenhouse gas emissions from fertilizer use and also enrich the local soil microbiome. This dual breakthrough delivers a substantial reduction in crop carbon footprints combined with a simultaneous increase in agricultural productivity.

Impact Zero is a cornerstone of Fertiberia’s sustainability strategy and has already been successfully implemented in collaboration with well-known agri-food brands, generating tangible progress in decarbonising their value chains.

The combination of state-of-the-art technology and a strong environmental commitment has made it possible to achieve a milestone for the sector: progressing toward more efficient, responsible agriculture that fully aligns with the UN Sustainable Development Goals – without compromising agronomic performance.

Success Stories – brands driving change

Impact Zero is already transforming the agri-food value chain from the ground up, thanks to Fertiberia’s collaboration with leading brands committed to a more sustainable agricultural model.

On an international level, Marks & Spencer has taken the bold step of incorporating Impact Zero in its UK dairy farms, fertilizing over 10,000 hectares of pastureland. Meanwhile, in France, the cooperative Vivescia has also begun applying the product range to its cereal crops.

In Spain, Fertiberia has built a strategic network of partnerships with farmers, cooperatives, suppliers, and operators across various agricultural regions, enabling Impact Zero to make a real and measurable impact on sectoral decarbonisation.

One of the most noteworthy collaborations is with Heineken España, which is implementing smart farming practices in its malting barley crops in Andalusia. The results are clear: up to a 62% reduction in the carbon footprint of the crop and a significant increase in the average yield of participating plots.

Grupo Gallo has adopted the product range in the cultivation of durum wheat – its main raw material – working closely with leading farmers and cooperatives to reduce its greenhouse gas emissions.

In a large-scale initiative, PepsiCo has applied Impact Zero across more than 3,000 hectares of potato and corn crops in Spain and Portugal. As a result, the first Lay’s and Ruffles potatoes grown with sustainable fertilization are now on the market, with emissions reductions of 15% for potatoes and 20% for corn.

Grupo IberoPistacho has incorporated Impact Zero as part of its decarbonisation strategy, as has Primaflor, an Almería-based company specialising in vegetables. Primaflor has introduced these products at its most advanced greenhouses, integrating their adoption with fertigation and water efficiency technologies.

Conesa Group, a European leader in tomato processing, has also started applying Impact Zero to its crops in Spain. The company aims to fertilize 250 hectares by 2025 and exceed 300 hectares by 2026, extending this practice to its associated producers.

Real change underway

These collaborations show that, together, innovation and environmental commitment are not only compatible, they also generate real transformation. Impact Zero is mobilising key players in the agricultural sector toward production that is more efficient, low-emission, and focused on the future.

Fertiberia is committed to a responsible agricultural model that improves the chemical, physical, and biological quality of the soil – firm in the belief that the transformation of food production in future begins with changes to the present.

OCP NUTRICROPS

OCP Nutricrops Green Solutions – sustainable solutions for green agriculture

Ethiopian farmer inspects his crop. OCP Nutricrops is on a mission to help farmers restore their soils and build more sustainable, productive agricultural systems.

Agriculture accounts for about 24% of global greenhouse gas (GHG) emissions, a level comparable to industry or transport. As global food demand grows, fertilizers remain essential for boosting yields, but also contribute significantly to emissions, particularly due to misuse or overapplication. To keep global warming below the 1.5°C limit set by the Paris Agreement and meet global food demand, agriculture must become a scalable lever for decarbonisation.

Ambitious low-carbon solutions

As a leading global phosphate fertilizer producer, our mission is to help farmers restore their soils and build more sustainable, productive agricultural systems. Through our commitment to sustainability, we continuously improve our offerings to ensure the world’s growing population can be fed nutritiously without impacting the planet.

OCP Nutricrops has launched its Green Solutions Business Unit – an initiative dedicated to shaping the future of sustainable farming. This new unit is focused on developing and deploying solutions addressing five key challenges: GHG emissions, water management, waste management, soil degradation, and deforestation.

The Green Solutions Business Unit complements OCP Nutricrops existing fertilizer offering by integrating carbon, water, and digital solutions to tackle sustainability challenges. These complementary solutions are designed to help stakeholders across the value chain. We work with farmer cooperatives and plan to engage with the wider agri-food sector to meet sustainability, traceability, and nutrition needs with tailored, responsible fertilization.

Two flagship initiatives

The Green Solutions Business Unit is advancing two flagship low-carbon initiatives; responding to the EU’s Carbon Border Adjustment Mechanism (CBAM), as well as supporting the goals of the Science Based Targets initiative (SBTi) being adopted by fertilizer users, from distributors and cooperatives to consumer goods companies.

• Closing the loop. This encompasses carbon capture from fertilizer production and waste valorisation. OCP Nutricrops aims to capture up to 80% of CO2 emissions from its phosphoric acid units, repurposing the recovered carbon as feedstock for new products. This approach fully aligns with a circular economy approach, turning emissions into resources and closing the industrial loop.

• Green fertilizers powered by green hydrogen: By 2027, OCP Nutricrops aims to produce up to three million tonnes of green fertilizers, using green hydrogen from electrolysis powered by Morocco’s abundant solar and wind energy, positioning the company as a leader in green ammonia and fertilizers.

Beyond carbon: circular and responsible operations

OCP Nutricrops is also transforming its operations by:

- Cutting Scope 1 and 2 emissions by 2030 and Scope 3 by 2040.

- At Group level, producing 1 million tonnes of green ammonia by 2027 and 3 million tonnes by 2032.

- Covering 100% of production water needs with non-conventional water by end-2025 – over 90% is already achieved at our Jorf and Safi plants.

- Aiming for 100% renewables by 2027 – over 80% of electricity today is generated in-house at our Jorf and Safi plants.

Triple superphosphate – a proven solution for sustainable agriculture

Alongside new low-carbon products, OCP Nutricrops promotes triple superphosphate (TSP), a phosphate fertilizer with about 46% P2 O5 , as a proven sustainable solution. TSP has a lower carbon footprint and offers several agronomic and environmental benefits:

• Soil health: Balances phosphorus in deficient soils and supports soil carbon and microbes.

• Water efficiency: Boosts root growth and drought resilience for better water use.

• Lower emissions: As a pure phosphorus source, TSP does not generate direct on-farm GHG emissions.

• Targeted delivery: Supplies the right phosphorous at the right time for healthy early roots.

• Environmental protection: Improves nutrient efficiency and cuts runoff, protecting ecosystems.

These benefits make TSP a smart choice for precise, efficient, and sustainable fertilizer use.

Committed to a sustainable future

Through the Green Solutions Business Unit, OCP Nutricrops is innovating in industrial processes and investing in circular, low-carbon technologies – delivering solutions that produce nutritious food, improve crop productivity, and strengthen climate resilience.

GOUDENKORREL

Taking Polyhalite further

GoudenKorrel S.A. is a Polish manufacturer specialising in multi-mineral compound fertilizers, with a strong focus on the innovative use of polyhalite as a core ingredient. The company is known for developing tailor-made, sustainable formulations that deliver immediate and measurable results – especially in vegetable and horticultural crops.

Going global in 20+ countries

GoudenKorrel now has a presence in more than 20 international markets, with strong sales performance in countries like India, Brazil, China, Vietnam, Colombia, and Senegal. Its polyhalite-based fertilizers have been widely embraced by farmers and agri-businesses, says Misael Machado, the company’s Export Sales Director, thanks to their proven effectiveness, sustainability, and crop-specific results.

New and upgraded nutrient formulations

GoudenKorrel is transforming the performance of polyhalite fertilizer via upgraded formulations, comments Machado, including the addition of water-soluble nitrogen and phosphorus.

“Five years ago, we began this adventure in partnership with ICL, our trusted supplier of polyhalite,” says Machado. “The idea was simple: take polyhalite further.”

For GoudenKorrel, ‘taking polyhalite further’ has involved transforming the mined raw mineral into a portfolio of advanced, high-performance fertilizers – these being designed to meet the specific needs of a diverse range of crops and different soil conditions. Today, the company offers four unique formulations, with Polyhalite Complex emerging as its flagship product – a product that’s proving particularly successful in key agricultural markets like India.

Polyhalite Complex is a polyhalitebased NPK compound fertilizer. It provides 11 crop nutrients in total – in contrast to standard granulated NPKs – containing additional Ca, Mg, Na and S alongside micronutrients (B, Fe, Mn and Zn), as well as being fully water-soluble and effectively chloride-free.

New crop trial results

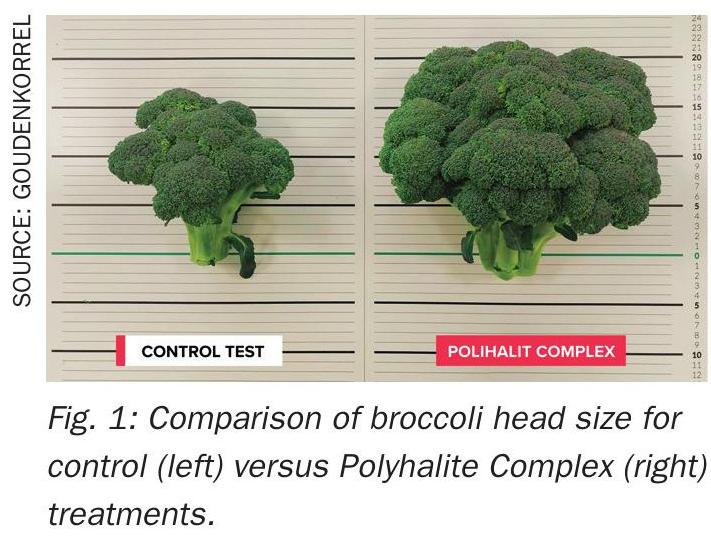

Recent trials with Polyhalite Complex have shown outstanding results in broccoli cultivation. In comparison to the control, its application pushed bud setting forward by 8–10 days and increased broccoli head weight by up to 59% (Figure 1).

The higher head weight shows that Polyhalite Compex provided the crop with a timely supply of necessary mineral nutrients, contributing to better yields and increased farm productivity. By promoting the development of aboveground parts, this polyhalite-based fertilizer improved both broccoli yield and the quality of the main edible organs.

Plants exhibited healthier, darker green colouration, indicating higher chlorophyll levels and better overall plant vitality. These improvements translate into higher yields, stronger plant resilience, and faster harvests.

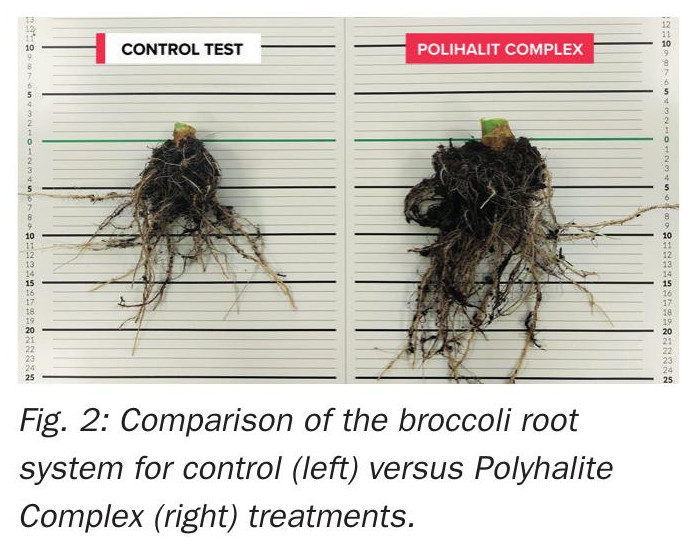

Measurements of the length and weight of the root system also confirmed the effectiveness of Polyhalite Complex in building stronger, more extensive roots (Figure 2). Root length increased by 36% and their weight increased by 43% compared to the control sample. These results testify to better uptake of water and nutrients, which is crucial for the stability and resistance of the plant to changing environmental conditions.

Another important effect of the polyhalite-based NPK fertilizer, versus the control, is the acceleration of the moment of setting of the broccoli heads. In the Polyhalite Complex treated crop, buds appeared 8-10 days earlier than in the control group, with broccoli plants showing a measurable improvement in their growth and development. The resulting faster maturity and earlier harvest makes the cultivation of broccoli more efficient.

Overall, Polyhalite Complex has proven to be an effective fertilizer for broccoli cultivation with significant positive impacts on crop development and quality. Higher head weight, a stronger root system, more intense colour and accelerated crop maturation are just some of the benefits of using this enhanced polyhalite-based fertiliser.

For GoudenKorrel, these results reaffirm our commitment to taking polyhalite further – by delivering tailor-made, sustainable formulations that boost crop performance while supporting more efficient, environmentally conscious agriculture.

OMNIA

FertiCoat – a unique biostimulant coating product

In an Australian wheat trial, the application of FertiCoat to the fertilizer increased yield by 16.5%, versus the control, without compromising crop quality.

In today’s economic landscape, growers face constant pressure to optimise their inputs and maximise crop yields. Nutrient use efficiency in particular – by indicating how well inputs are delivered to the crop – plays a pivotal role in measuring and enhancing the performance of applied fertilizers.

To help answer these farm productivity concerns, Omnia has introduced FertiCoat, an effective biostimulant coating for fertilizers. Designed for ease of application, its primary goal is boosting crop yields, and therefore farm profits, by improving fertilizer efficiency.

The unique combination of biostimulants present in FertiCoat – including seaweed, humates, fulvates and amino acids – promotes plant growth and enhances crop resilience to both biotic and abiotic stresses. FertiCoat also acts to increase plant nutrient uptake through the root system.

FertiCoat serves as an excellent granular coating for NP, NPK and urea, and also functions as an effective additive for liquid fertilizers like urea ammonium nitrate (UAN). Crucially, when added to urea, FertiCoat ensures that nitrogen stays in the root zone, preventing wastage and nutrient loss through volatilisation and/or leaching.

Preventing crop burn

When integrated with UAN, FertiCoat brings tangible advantages for both soil-applied or foliar applications. Moreover, its buffering effects on nitrogen content are conducive to microbial and mycorrhizal activity in soils.

For crops like wheat, UAN is commonly applied as a foliar solution. Under specific conditions, however, this may have a damaging effect on yield potential due to crop burn. Valuably, the addition of FertiCoat significantly reduces the likelihood of leaf burn or scorch by neutralising the harmful effects of biuret. The Humic and fulvic contents of FertiCoat also promote foliar uptake and minimise nitrogen volatilisation.

Ease of application

FertiCoat can be applied to granules using various equipment, such as granulation drums, coolers, coating drums, blenders, screw augers, or conveyors. Independent trials conducted on crops worldwide, both in the field and greenhouses, have consistently demonstrated FertiCoat’s superiority as a coating product, showcasing its ability to increase nutrient use efficiency and farm profitability.

Look out for a longer feature article on FertiCoat in the forthcoming September/ October issue of Fertilizer International.