Nitrogen+Syngas

31 January 2017

Problem No. 40: Medium pressure absorber in Saipem urea plant

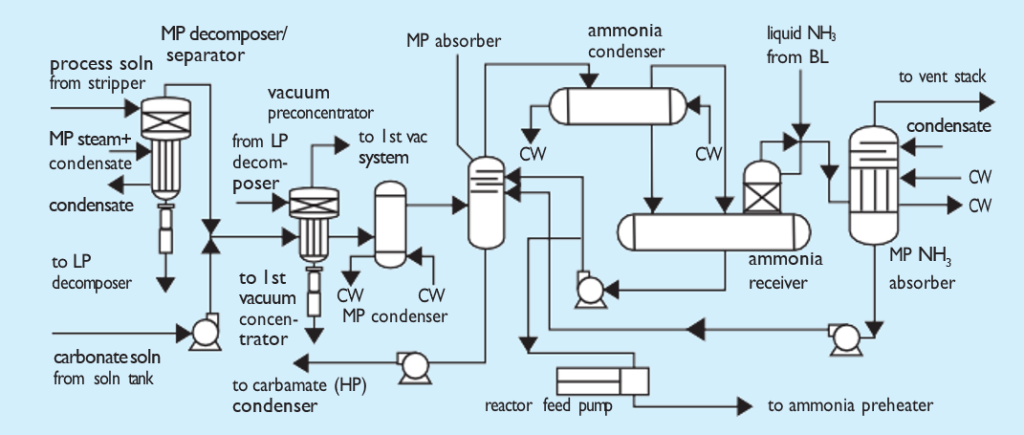

The function of the medium pressure (MP) absorber is to separate pure ammonia from ammonium carbamate before both of these streams are recycled to the synthesis section. Control of the process conditions of the MP absorber is one of the key control parameters in a Saipem urea plant. CO2 carryover to the ammonia receiver is not permitted in the process as it will create corrosion problems and upset conditions in the ammonia recovery and pumping system. This round table discussion considers the problems and solutions in this process section.

Nasir Hussain from Pak Arab Fertilizers Multan, Pakistan starts the round table discussion: Please tell me about problems with the medium pressure absorber in a Saipem urea plant. What is the allowable CO2 carryover to the ammonia receiver?

Siddharth S from TATA Chemicals ltd, India replies: High temperatures above the first tray and high levels and/or partial choking of the trays may cause CO2 carryover from the MP absorber. If the problem persists there could also be some passing between the joints of the tray segments and inlet pipe sparger joints (gasket may be damaged). Proper sealing on the joints is a must. This may be checked during shutdown by observing the water retention period on the trays (normal retention time for water should be more than 20 minutes). During normal operation there should be no CO2 carryover to the ammonia receiver.

Girish Prakash from TATA Chemicals Ltd., Babrala, India shares more experiences: Level fluctuations in the column during start-up/upset conditions are very common for this equipment. You need to pay attention to the actual liquid level in the column.

Mohd Saiful Mohd Sofian from PC FK, Malaysia raises a question: Has anyone implemented any improvements in this unit? There is a patented technology claiming to be able to eliminate this problem. Does anyone have any more information?

Girish Prakash from TATA Chemicals Ltd., Babrala, India explains what he has done in his plant: We have made internal improvements without any external help. If you have any particular thing in mind, please share so that we can also benefit.

Azad Panchal from GNFC, India asks a question: Can anyone tell me why the upstream temperature is kept as high as 88-90°C in the MP absorber? Prem Baboo from National Fertilizers Ltd, India answers the questions and shares some documents: The MP absorber is the heart of the Saipem urea synthesis section. This is the vessel where pure excess ammonia is separated from ammonium carbamate. To operate at the right temperature is key for good performance of this absorber. The top temperature must be maintained at 42-43°C, while the bottom temperature is maintained at about 72-80°C. If the bottom temperature is below 70°C the ammonia will not evaporate and goes to the HP carbamate pump leading to cavitation risks. For the complete troubleshooting process refer to the UreaKnowHow.com website.

Muhammad Umar Munir from Pakarab Fertilizer, Pakistan provides more information and asks another question: The MP absorber (C-1) at our plant has a bottom temperature of ~82-84°C. The middle tray temperature is also high i.e. 60°C but the top tray temperatures are okay. I have requested the lab results and will share them with you but according to the sheet prepared by Prem Baboo, there is a probability of CO2 carryover. The corrective action recommends checking the E-7 temperature. I carried out this check and it is running at 82°C (E-7 outlet).

My question is: What is the optimum temperature at the E-7 outlet? Also, is there any other reason that could contribute to this observation?

Prem Baboo from National Fertilizers Ltd, India replies to the question and shares a valuable document: Good question. The bottom temperature 82-84°C is not a problem – it is slightly higher than the design temperature of 75°C. It is beneficial because the higher the temperature the more ammonia is evaporated from the bottom to the top and the less recycle there is. The top temperature is OK. The 2nd tray temperature being higher is not a problem and is likely due to the fact that you have more water going to C-3 (inert washing column). This ammoniacal water is increasing the 2nd tray temperature.

The E-7 (MP condenser) process outlet design temperature is 78°C and the cooling water outlet design temperature is 66°C. E-7 is the critical equipment item, where control of sedimentation of the cooling water is important which is influenced by the opening of control valve TV 101. If the TV 101 opening is reduced there is a chance of sedimentation and scaling of phosphate/silica. In this case you must control the flow by opening TV 105.

Below are some points for your attention:

- Ensure sufficient cooling water flow in E-7, to avoid sedimentation.

- The cooling water outlet temperature of E-7 should not exceed 66°C as at higher temperatures scaling takes place.

- The inlet temperature of the cooling water to E-7 should be no less than 35°C to avoid crystallisation on the shell side (carbamate solution).

- The outlet temperature of E-7 (process) is optimum at about 78-80°C.

- The bottom temperature of C-1 should be 75-82°C.

Recently we carried out a modification to C-3 (inerts washing col- umn): ammoniacal water was taken from E-8 (LP condenser). The following advantages were noticed:

- C-1 temperature control;

- reflux to C-1 reduced by 2 m3/hr. i.e. reduction of recycling flow;

- LP pressure control and the total cold water flow to C-4 (LP inerts washing column) is stopped;

- V-3 (L.P carbonate solution tank) level control;

- P-7 (inerts washing ammoniacal pump) now stopped the solution transfer by deferential pressure of MP and LP;

- power saving due to stopping the motor.

Muhammad Umar Munir from Pakarab Fertilizer, Pakistan provides more figures and information: That clarifies a lot. I’ll come back once I get lab results, but in the meantime I would like to show you the operating conditions from this morning:

The tray temperatures are okay so I am not expecting any carry over and the higher middle temperature is probably due to the same phenomenon as the bottom one.

| Temperature, °C | Design | Operating |

| Bottom | 70-75 | 82.0 |

| Middle | 45-50 | 55.0 |

| Tray 1 | 45-50 | 49.0 |

| Tray 2 | 40-46 | 45.0 |

| Tray 3 | 40-45 | 42.0 |

| Vapour overhead line | 40-45 | 47.0 |

These are the results of the MP absorber bottom effluent: NH3 44 wt-%, CO2 26.7 wt-%, H2O 29.3 wt-%.

The tray temperatures corresponding to these results are:

Bottom: 86°C; Tray 1: 54°C; Tray 2: 47°C, and other temperatures are the same as given by you.

Apparently, there is an increasing trend of C-1 bottom temperatures. Moreover, the water content seems to be on the high side with relatively less ammonia. This means there is minimal chances of P-2 cavitation but what impact does a higher water content have?

Prem Baboo from National Fertilizers Ltd, India shares more information: The higher percentage of water may be due to disturbances in the common section. If your top temperature of C-1 is maintained there is no problem at all. The main sources of water for the ammonium carbonate solution tank are:

- Common section (waste water section) reflux accumulator ammonia wt-% is low: design is 35 wt-% but in practice 32-35 wt-%.

- Your LP section pressure is low resulting in water carryover to V-3 (ammonium carbonate tank), the pressure/temperature equilibrium not matching.

- Distillation tower (C-2) feed check ammonia wt-%

- Check water balance of vacuum section (i.e. steam to booster ejector)

- Cold water to C-3/E-11 (inerts washing column) is increased.

- Check also upstream.

If you have sufficient margin in TV 101 then reduce the outlet temperature to 70°C. But the inlet temperature must be watched – design is 40°C but you reduced to 35°C.

Shahbaz Soomro from FFC, Pakistan joins the discussion: What about flushing of the C1 trays? Were there no problems of C1 trays choking after this modification?

Prem Baboo from National Fertilizers Ltd, India replies: After this modification the temperature of the 3rd tray (from top) came down drastically. High temperature favours the carryover of CO2. To date, there is no problem of choking and this modification is recommended by Saipem. In India, two plants have been implemented with this scheme.

Manikanta Vema from Kribho Fertilizers, India asks for further information: Thank you for the information about your C3/E-11 modification. I would like to know what the overall effect is on the total steam as a result of this modification apart from the power saving of the P-7 motor?

Prem Baboo from National Fertilizers Ltd, India replies:

The following advantages were observed:

- Water reduced in the process by 1.0-1.5 m3/hr.

- Reflux reduced in C-1 (MP absorber) by about 2.0-3.0 m3/hr.

- Overall (steam to distillation, steam to LPD, etc.) LS (low pres- sure steam 4.0 bar) reduced 2.0-3.0 t/hr. Also LS generation in E-5 (HP carbamate condenser) increased by 1+1 =2 t/hr.

- Waste water feed reduced by 1.5 to 3.0 m3/hr.

- KS (105 ata) reduced by 0.5 to 1.0 t/hr.

The above modification was only carried out in line-II Plant (expan- sion), line-I modification approval under progress.

Manikanta Vema from Kribho Fertilizers, India asks a new question: After this P-7 modification, have you faced any problems with C-1 tray temperatures, because the P-7 water helps to flush the trays to avoid partial choking?

Prem Baboo from National Fertilizers Ltd, India answers to the question: After P-7 (aqueous ammonia pump) stopped we did not experience any problems of trays choking. This ammoniacal water was taken from tray No 2 (from top). Due to absorption the temperatures of the 2nd, 3rd & 4th trays (from the top) were running higher, so the possibility of CO2 carryover was greater than now. Due to the higher tray temperatures the reflux quantity was also higher.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |