Nitrogen+Syngas 325 Sept-Oct 2013

31 October 2013

Problem No. 20: Unblocking pipelines after a urea plant shutdown (continued)

In several sections of a urea plant pipelines, and sometimes heat exchangers, can easily become blocked below a certain temperature and crystallisation can take place. In the evaporation section, urea melt is present which crystallises at about 133°C when in the pure form.

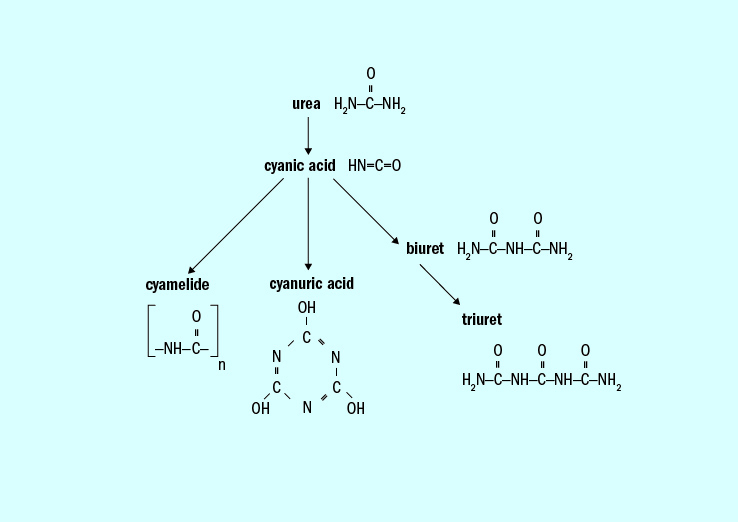

Urea can also polymerise to form biuret, triuret and polyurea with high crystallisation temperatures when urea is kept for a prolonged period at high temperatures.

Possible reaction products formed from urea during exposure to high temperature:

The internals of other equipment can also suffer from these problems (see picture below, showing poly-urea in the internals of a vacuum separator).

In the recirculation section, ammonium carbamate is present which crystallises at about 153°C maximum when in the pure form. In the high pressure synthesis section, urea and risk of lines and heat exchangers becoming blocked is small, however during a plant shutdown blocking can occur when the right measures are not taken.

In other industries, applying heat may be a normal procedure when solids block a pipeline or heat exchanger. In a urea plant it is a little more complicated when solid ammonium carbamate is heated up it decomposes into gaseous ammonia and carbon dioxide. When urea is heated up, however, it partly decomposes into gaseous ammonia and isocyanic acid and partly reacts to produce other products like biuret, triuret and other poly urea molecules, which have even higher melting points. Pure biuret, for example, has a melting point in the range of 185-192°C and pure triuret 231°C. Alternative measures are therefore required to unblock pipelines and heat exchangers. This discussion looks at which measures to take and what to do when a line is blocked and is a follow-up of an earlier Round Table Discussion.

Mr Manzoor Ahmad Taraqfdar of Bangladesh Chemical Industries Corporation in Bangladesh introduces the problem of blockages in urea plants after shutdown: After a shutdown, when we are ready to start-up, on several occasions we have experienced a line blockage. We are not sure whether the white material is ammonium carbonate or ammonium carbamate. Normally this blockage can be removed by hot water, but when water washing is not possible without dismantling the pipeline we have tried flame heating of the pipe from the outside by removing the insulation. However, most of the time it was unsuccessful and it was necessary to dismantle the pipeline. I would like to know the following:

- What is the white material?

- How to avoid its formation after a shutdown?

- What is the standard method for unblocking?

Previous discussions have provided a number of explanations to these questions:

The white material may be urea or ammonium carbamate, which solidify upon cooling or when they have sufficient time to solidify. Biuret, triuret and other poly-urea components are also white materials, so it is not possible to identify which solids are formed from the colour. A possible cause of blockages can be the improper flushing of the sections during the shutdown procedure. After shutdown, all sections should be thoroughly flushed with hot condensate.

To avoid blockages, it is always recommended that, in each shift, the drains of all critical lines subject to blocking are checked. If the line has tracing it should be in service and it should be ensured that the steam trap isolations are removed and they are in service.

One method to unblock lines is to heat either directly by injecting condensate or steam into the pipeline or by indirect heating via a flame or steam outside the pipeline. If the blockage can be located it can be targeted at that point. If the point of blockage is not known, the flanges in the line can be opened and direct heating can be applied. However, care should be taken when unblocking the pipelines in a urea plant by flame heating because overheating or localised heating may cause thinning and damage of the pipeline as has been experienced during the unblocking of a reactor drain line. Heating up austenitic stainless steels like 316L UG or 25-22-2 and duplex steels can adversely affect the corrosion resistance of these materials. For example, heating 316L UG above 500°C will increase the corrosion rate as chromium will form chrome carbides Cr23C6 with any carbon present in the steel along the austenite grains. This causes depletion of chromium from the austenitic grains, which reduces the protective passive film.

Another option is to dilute the solution (in cases where the solution is being held) with condensate.

Other critical areas where blocking can occur:

The same thing happens mostly in urea melt lines where solidification is quick after shutdown if the drain line is also found to be blocked.

Another critical area is high concentrated (99%) urea heat exchangers in the vacuum stage. Concentrated urea solution if allowed to remain stagnant at higher temperature in the heat exchanger can result in the pyrolysis of urea to form biuret/triuret. This problem can arise say if 99% urea pumps lose suction for any reason, steam to the heat exchanger is open and solution is stagnant in the heat exchangers for some time. Removal of this sort of blockage is not possible by steaming.

Other solutions for unblocking:

Mr Rajkumar Kularni of RCF LTD in India offered an interesting suggestion to identify areas where the temperature has dropped due to problems. He suggested providing skin temperature measurements for the most probable and difficult to access points. This is a low cost solution which can immediately detect any problem, and can also help in isolating/identifying the problem area (blockage) thus helping to solve the problem quickly.

Mr Jayant Panvelkar of Zuari Industries Limited in India introduces another solution: We have a melter in our urea crystallisation section and during shutdowns we circulate 10% caustic solution at 95°C to remove biuret deposition. Urea can react with caustic soda forming sodium cyanate, ammonia and water according the following reaction:

NaOH + (NH2)2CO → NaOCN + NH3 + H2O

Biuret, triuret and other poly-ureas also dissolve very well in urea melt and many urea plants apply urea melt flushing connections to get rid of this fouling. Of course these flush lines need an after flush of water to avoid urea blocking.

Follow up discussions:

Mr Tarun Batra of National Fertilisers Limited in India continues the discussion by sharing his experiences: We experienced a blockage problem in the second stage evaporator heat exchanger, following stagnant 99% urea melt at high temperature. Blocking is most likely due to condensation products of urea/polymerisation products.

Due to the low heat transfer caused by some completely blocked tubes, we can only manage operations with an increased steam pressure.

Mr Rajan Khular of Chambal Fertilisers & Chemicals Ltd. in India contributes with his experiences: The first thing that is taught to someone new to the urea plant is of course the crystallisation temperature of urea melt. Flushing and re-flushing to ensure clearance of all critical headers is a must for trouble free start-up of urea plants. Reaching a stage requiring local gas heating indicates total negligence immediately after plant stoppage. In fact the only two things of concern immediately after shutdown are the thorough flushing of the vacuum section and the discharge line of the carbamate feed pump. Typical carbamate blocking of the ammonia condenser in a Saipem urea plant, due to carryover of carbon dioxide from the medium pressure absorber, can be cleared by repeatedly filling and draining hot water on the shell side of the condenser.

Mr Waqas Habib of Engro Fertilizers Limited in Pakistan comes up with two possible causes: If the blockage has occurred, even after adequate flushing, consider the following:

- There may be an opportunity that allows the reaction of ammonia and carbon dioxide vapours even after the flushing is complete.

- The pipe is not steam traced or if it is traced, the tracing steam valve is either closed or its steam trap is blocked.

Mr Mark Brouwer of UreaKnowHow.com in the Netherlands draws attention to a related article in the E-Library of UreaKnowHow.com: “1931 Davis Ind Eng Chem Liquid Area of Urea-Ammonia-Carbon Dioxide System”, which indicates the crystallisation temperatures of various synthesis mixtures.

Mr Ease Norozipour of Khorasan Petrochemical Company in Iran provides recommendations and a new solution for unblocking: Besides the points already mentioned, I think the following items should also be considered:

- tracing and isolation must be checked and in service;

- flushing of lines must be performed carefully before and after each shutdown;

- check valves in the pipelines must be checked to ensure they are working properly;

- the isolation valves must be checked to ensure they are working properly;

- direct flame heating is not good for unblocking. We have used a thermal stress relief device to control the temperature.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |