Nitrogen+Syngas 319 Sept-Oct 2012

31 October 2012

Problem No 14: High synthesis operating pressure

Operating at the wrong synthesis operating pressure is always a tricky situation for any urea plant operator, knowing that operating at too high a pressure will lead to the pressure safety valves blowing off. Such an incident would not only cause a significant environmental impact but also a forced shut down of the plant as typically the pressure safety valves no longer close properly after blowing. Servicing these valves becomes necessary and plant down time can be a costly incident. On the other hand, operating at too low a synthesis pressure will lead to lower conversion figures, higher carbamate recycle streams and higher energy costs.

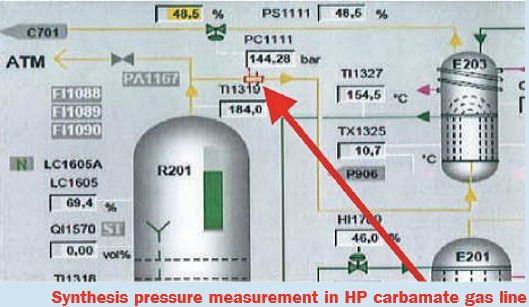

The key is to measure the synthesis pressure in a reliable way. In an ideal situation, the synthesis pressure would be measured as close as possible to the pressure safety valves, e.g. in a high pressure carbamate gas line. Until recently this was not possible because of the risks of crystallization and corrosion so the synthesis pressure has mostly been measured at locations where these risks are absent or less likely.

Now LESER, together with SKW Piesteritz, has developed a reliable solution to measure the synthesis pressure in the high pressure carbamate gas lines. But what should others do who don’t have reliable synthesis pressure indication?

Mr Kumar Srivastava of Notore Chemical Limited in Nigeria starts up a discussion about a high synthesis operating pressure: Our urea plant is based on Stamicarbon CO2 stripping technology. We are facing problems of high synthesis pressure when we try to go to a load of approximately 122%. My observations are as below:

- In our plant the synthesis loop pressure reference is taken from upstream of the high pressure ammonia ejector (in the ammonia feed line) and the instruction is to maintain the synthesis pressure at 150 kg/cm2 based on this HP ejector upstream pressure. The ejector pressure control valve is kept fully open. However, from the ejector data sheet we can learn that at normal plant load the differential pressure across the ejector is 15.5 kg/cm2.

- My concern is that carbamate may be building up, leading to a false high synthesis pressure indication and poor reactor conversion due to the low reactor pressure (seeing differential pressure), which increases the water recycle in the system, thus reducing reactor conversion even further due to the high water ratio.

- In our plant there is no gas chromatograph (or molar N/C ratio analyser).

- I am seeking help: When keeping the HP ejector pressure control valve fully open, is it possible to maintain a differential pressure across the HP ejector as per design value? This HP ejector is installed in the HP ammonia pump (7 plunger reciprocating type) discharge line. Is it possible to throttle the HP ejector valve to increase the driving pressure, which may help to create a higher differential pressure, which in turn will help to reduce the supposed build up of carbamate from the HP ejector?

Mr Salam M. Maleh from North Fertilizer Complex in Iraq replies: You can control the differential pressure (18 bar) by controlling the HP ejector throttle valve (close ejector throttle valve for example 5%).

Kumar asks for further clarification: Does your plant have the same technology? I don’t know the capacity of your plant or if you have a HP ejector in your plant. I understand the concept of the HP ejector very well, but I don’t have the HP ejector performance curve.

Mr Shoaib Minhas of FFBL in Pakistan contributes to the discussions with his experience: We have a centrifugal type HP ammonia pump and we manipulate the ejector valve to control the back-pressure (ammonia pump discharge pressure). You may also wish to consider this as you have a reciprocating type pump.

Mr Muhammad Farooq of Agritech in Pakistan shares his view: In a Stamicarbon urea plant it is more important to control the N/C ratio and reactor top temperature to control the synthesis pressure.

Mr Majid Mohammadian of OCI Nitrogen in the Netherlands requests more details: Can you tell us the following?

- Plant nameplate capacity

- Capacity you are limited to

- Synthesis pressure

- Pressure upstream of the HP ejector

- Scrubber overflow line temperature and level

- Feed ratio and if possible N/C on reactor downcomer

- Top temperature of the reactor

- Gas outlet temperature of the HP scrubber

- Is it a vertical HP carbamate condenser or pool condenser type?

Kumar replies:

- Plant nameplate capacity: 1,500 t/d

- Capacity limitation: >90%

- Synthesis pressure: about 140 kg/cm2

- Pressure upstream of the HP ejector: 158 kg/cm2

We have a vertical HP scrubber. The solution outlet temperature is 165°C and the reactor vapour temperature is 168°C. This indicates to us high ammonia and we tried to increase the CO2 a little. Do you have level indication in your HP scrubber? I ask because in our plant there is no level indicator so we do not know if there is any level rise when there is an increase of carbamate flow. But the increased opening of the vent valve indicates that there is a level increase in the HP scrubber which is why I want to operate the HP ejector to increase differential pressure across the HP ejector.

Majid replies: Normally in our Stamicarbon plant there is a level indicator in the scrubber overflow line to control the level in the line because we need to prevent any gas passing or gas circulation in the synthesis section. Please provide the following information:

- With the synthesis pressure transmitter being located and as per your design what should the synthesis pressure be at 100% capacity?

- What is the temperature of the gas outlet from the scrubber?

- As per your PFD, what is the inlet and outlet pressure of the ejector at 100% capacity?

Mr Muhammad Kashif Naseem of SABIC in Saudi Arabia requests some further information: Please tell me the followings to help solve your problem:

- HP vent out temperature

- LP steam pressure

- Reactor top /bottom temperatures

- Stripper top /bottom temperature

- Stripper steam pressure

Kumar replies: We don’t have any level indicator in the HP scrubber vessel. Please send me the details for a level transmitter in the HP Scrubber such as the vendor and where it is mounted.

We also have level transmitter issues in the 2nd stage evaporator: Presently the level indicator is mounted in the suction line of the melt pump and is not working. We need to change this level transmitter. In your plant where is this level transmitter mounted and who is the supplier?

Mr Muhammad Adnan Hanif of Fauji Fertilizer Company Limited in Pakistan shares his experiences and asks for some clarifications: What is the reactor bottom pressure [any pressure transmitter or local PI installed downstream of the HP ejector or CO2 inlet line to urea reactor just downstream of the shut down valve]? Normally the pressure throttle valve installed on the HP ejector is utilised to regulate carbamate flow. If your plant N/C ratio is satisfactory or higher than required you can utilise this valve to increase the motive fluid i.e. ammonia pressure. However, please note that the delta-P of 15.5 kg/cm2 [Between HP ejector upstream and HP loop top vent] will not give you a true picture of the available head to move carbamate. You should take the reactor bottom pressure and the motive fluid pressure difference. Normally, in our plant [Saipem technology] it is > 60 kg/cm2 [Delta P between reactor bottom and ammonia header]. To check if there is any liquid passing to downstream sections through overflow of the HP scrubber, check its effect on downstream section e.g. sudden decrease in temperature, pressure excursions etc.

Mr Krishan Harit of Qafco in Qatar shares his experiences: Are you sure that your plant is facing a problem due to the HP ejector. Your synthesis pressure tapping is in the wrong location. If you reduce the HP ejector opening then the pressure upstream will increase and more carbamate from the HP scrubber will go to the HPCC, which is good.A HP scrubber level indication is not required; generally this indication is not working anyway.

The best method of control is to use the HP scrubber outlet temperature. If the temperature is low it means your HP scrubber level is high (166-168°C is a good temperature) but if the temperature is 165°C or less it means the HP scrubber level is too high and liquid is going to LP absorber. You can see this by the increase of the LP absorber level opening and the synthesis pressure increase, in which case a closer HP ejector opening will help.

The best place for the synthesis pressure indication is the HP scrubber overflow line or downstream of the HP ejector in the line to the HPCC.

Mr Mark Brouwer of UreaKnowHow.com in the Netherlands summarises the discussions so far: In order to have more efficient discussions it would be better to have more information from the start with regard to temperatures, pressures etc.

It is important to know the basic process technology one is referring to as in this case it is important to realise that the HP ejector in a Stamicarbon plant has a different function to that of the HP ejector in a Saipem plant.

The challenges to measure the synthesis pressure in a reliable way, without crystallisation and corrosion risks, is different for each technology. In both technologies one looks for places where these risks are minimal but these places differ between both technologies.

One can easily conclude that, in this particular plant, the pressure measurement, located upstream of the HP ejector, is far from ideal. Depending on plant loads and carbamate flows, the delta-P over the HP ejector can differ significantly (I have seen ranges from 15-35 bar). It is therefore important to have the datasheets for the HP ejector. For anyone considering a new pressure measurement in your synthesis, please note the presentation of LESER at the AICHE Ammonia Safety Symposium on September 13, 2012 in Chicago.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |