Nitrogen+Syngas 310 Mar-Apr 2011

30 April 2011

Problem No. 5: H₂SO₄ injection in urea melt

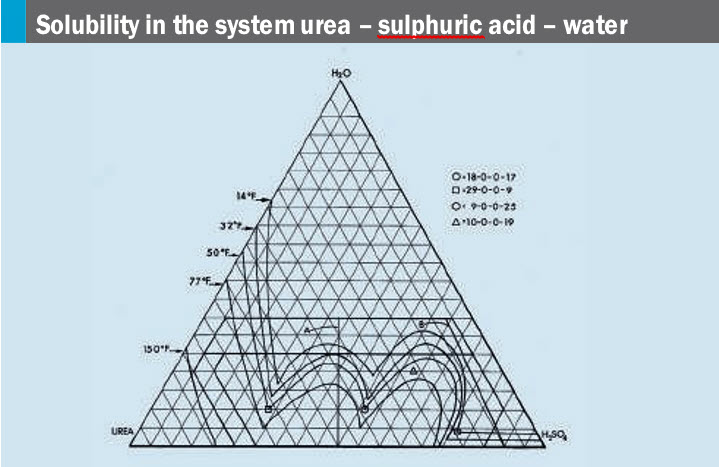

The urea industry continuously strives to reduce ammonia and urea dust emissions from urea plants. The previous reported Round Table discussion (No.4) collected different solutions actually being applied in urea plants to reduce gaseous ammonia and urea dust emissions. This time a new, interesting and challenging possible solution, injecting sulphuric acid (H2SO4) in the urea melt, will be discussed. This solution was tested at Phu My Fertilizer plant in Vietnam and immediately prompted a lively discussion in the UreaKnowHow.com Round Tables. The mixing of urea with sulphuric acid was already the subject of research programmes in the early 1980s and the information available in the public domain was helpful in gaining a better understanding of the phenomena observed.

Mr Le Ngoc Ban from Operations at Phu My Fertilizer plant in Vietnam posts an interesting experiment in the Round Tables:

Today I injected sulphuric acid (H2SO4 98 wt-%) into the urea melt solution at the top of the prill tower. The injection point is at the suction of the urea melt pump. The problem is that the current and discharge pressure of the pump are gradually decreasing when the acid flow rate is gradually increasing. What happens with the melt pump? Does it cavitate? Does anyone have experience of this?

Mr Muhammad Farooq of Pak-American Fertilizer Limited in Pakistan asks for some clarifications as this experiment is quite unique in the industry:

Can you tell us why 98 wt-% H2SO4 has been injected into the urea melt? What are the expected benefits? Please provide more details of your experiment.

Mr Mark Brouwer of UreaKnowHow.com in The Netherlands also requests additional information and provides some initial suggestions:

An interesting experiment!

How much sulphuric acid did you inject?

Do you want to reduce the ammonia emission from the prill tower or do you want to produce urea/AS product?

I would expect the formation of ammonium sulphate, which is able to dissolve in a urea melt up to a certain percentage. I guess the density increases when injecting H2SO4 which should lead to a higher current at the same flow rate, but maybe gas formation occurs. Did the flow decrease when you injected H2SO4? Did the temperatures change?

Mrs Saima Abdul Rasheed of Pak-American Fertilizer Limited in Pakistan replies with valuable information:

The reaction between sulphuric acid and urea is highly exothermic (US Patent No. 4445925 and 4310343). Some vapour formation might have occurred.

Mr Le Ngoc Ban replies to the questions raised earlier:

To Muhammad Farooq: The purpose of this injection is to reduce the ammonia content in the prilling top as per environmental requirements.

To Mark Brouwer: The H2SO4 injection flow rate is 0.11 m3/h (design), but when I did this test, I increased the flow rate in three steps: 0.04 m3/h; 0.08 m3/h; 0.11 m3/h.

- Yes, I want to reduce the ammonia emission from the prill tower exhaust.

- Yes, the urea melt temperature increased by about 2.7 – 3°C resulting in a biuret increase!

When I increase the acid flow rate, the current of the melt pump decreases so I think the density of the urea melt decreases. You said that gas formation occurs, but what is the gas? When I stop the acid injection the current and discharge pressure of the melt pump increases again.

Steps: 0.04; 0.08; 0.11; 0.00 m3/h

Current: 117; 115; 113; 119 A

Discharge pressure: 13.4; 13; 12.8; 14.5 bar

Biuret content: 0.97; 1.07; 1.09; 0.95 wt-%

The plant load did not change.

Mr Muhammad Farooq suggests an alternative to bypass the problems:

I would like to suggest that you inject H2SO4 in the discharge line of the urea melt pump near the prilling bucket by using an acid dosing pump. Do you have any washing/scrubbing system at the top of your prill tower?

Mr Muhammad Naeem of the Technical Services Department of Pak-American Fertilizer Limited in Pakistan contributes to the discussion with a valid remark:

I think the proper way to inject any kind of fluid irrespective of whether it is UF-85 or H2SO4 is to inject it at the suction of the urea melt pump to achieve a better mixing of both fluids.

Mrs Saima Abdul Rasheed replies to Mr Le Ngoc Ban’s question:

The vapours formed are water and the acid.

Mr Mark Brouwer elaborates further:

Yes and urea can also decompose into NH3 and HNCO gases: this reaction might also be promoted when H2SO4 reacts with NH3. Plus, when the temperature increases, more vapours form. Mr Le Ngoc Ban raises some more questions:

Do you have any documents about H2SO4 injection into urea melt? What kind of side reaction happens in this solution? How do you explain the increase in biuret content?

And why does the urea melt pump cavitate?

Mr Mark Brouwer replies:

Please study carefully the patents indicated by Saima Abdul Rasheed. These patents mention exothermic reactions and even explosion risks. As by-products CO2, NH3 and toxic components like ammonium sulphamate and sulphamic acid are mentioned. Be careful, when the ammonia concentration reduces due to reactions with sulphuric acid, the biuret formation reaction:

2 urea <=> biuret + NH3 goes to the right side. This leads to more biuret. More gases cause cavitation of the pump.

Mr David Herrero from Operations at Fertiberia, S.A. in Spain gets involved in the discussion and provides valuable new information:

One can find several patents on the web regarding sulphuric acid injection into urea melt. They claim that the ammonia emission from the prilling tower could drop to 5 mg/Nm3 without fur ther air treatment. The biuret content will increase slightly and the final content of the ammonium sulphate would be around 0.5%. The water content would not be affected if 98% sulphuric acid is used. The point of injection is at the pump suction line to assure correct mixing and reaction with the free ammonia. If enough gases are present due to the reaction, cavitation, of course, will take place.

The ammonium sulphate content makes this urea only valid for agriculture (not industrial grade). As far as I know, there was limited real experience (I guess this would have been more widely practiced if it was very successful).

Did you run the trial for a long enough time to enable the ammonia emission to be measured? If so, what were the values you got?

Mr Ahsan Muhammad Sarfraz of Fatima Fertilizer Ltd in Pakistan asks a few more questions:

Really interesting experiment, but may I ask what the present level of ammonia emission at your prilling tower is that you are tr ying to control? In addition, what was the impact on the ammonia emission of the tower during the time you had dosed the acid (did you measured the impact?).

What emission level are you aiming for – TEC and Stamicarbon prill towers usually operate at around 25 mg/Nm3. We are operating at 14 mg/Nm3.

Mr Le Ngoc Ban replies:

The test lasted for 7 hours, from 9 am to 4 pm.

Steps: 0.04; 0.08; 0.11; 0.00 m3/h

NH3: 78; 49; 89; 94 mg/m3

Actually, the ammonia level at the prill tower depends on where you take the sample. In our case, the highest level is 94 mg/m3 and the lowest level is below 60 mg/m3. My target is to reduce the level of ammonia to below 60 mg/m3.

By the way, do you think the prill hardness could improve after H2SO4 injection?

Mr Basheer Al-Awami of SAFCO in Saudi Arabia contributes some new and interesting aspects to the discussion:

It is an interesting subject. Injection of H2SO4 or ammonium sulphate is going to improve the mechanical strength of the urea prills and also reduces the ammonia emission. However, one should be worried about the corrosion that may occur in the prilling tower structure. Also the colour of the final product may appear yellowish, which may be not accepted by farmers.

Mr Vedantam Srinivas of SAFCO in Saudi Arabia contributes to the discussions with an interesting alternative to reduce the ammonia emission:

You were doing a good experiment.

Do you have a dedusting arrangement in the prill tower top? What is the height of the tower and flow of air through the tower?

Based on the above, you may consider using water or H2SO4 as the scrubbing media. Ammonium sulphate can also be produced as a byproduct.

Mr Le Ngoc Ban replies:

We do not have a dedusting system in the top of the prill tower.

Mr Gh. Serpoush of R&D of Shiraz Petrochemical Company in Iran confirms the biuret increase and raises another question: OK, the urea melt temperature increases about 2.7-3°C, which increases the biuret content.

What is the ratio (mole H2SO4/mole urea) in your test or how many tonnes of urea were prilled during the test?

Mr Le Ngoc Ban replies:

The plant load when I did the test was about 99 t/h, you can calculate the H2SO4/urea mole ratio.

Now we are awaiting the result of the prill hardness test. We hope that the hardness will be improved.

| This series of discussions is compiled from a selection of round table topics discussed on the UreaKnowHow.com website. UreaKnowHow.com promotes the exchange of technical information to improve the performance and safety of urea plants. A wide range of round table discussions take place in the field of process design, operations, mechanical issues, maintenance, inspection, safety, environmental concerns, and product quality for urea, ammonia, nitric acid and other fertilizers. |