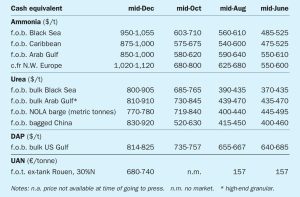

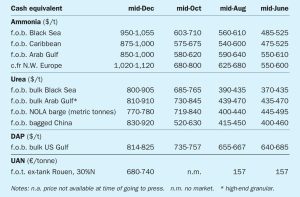

Price trends

Market Insight courtesy of Argus Media

Market Insight courtesy of Argus Media

Stamicarbon offers advanced scrubbing technologies for fertilizer granulation plants and prilling towers. This article describes the technology and experience with the second operational MMV scrubber, which is installed at the Dakota Gasification Company’s (DGC) urea granulation plant, and highlights the successful pilot test with its JV scrubbing technology.

The consistency and integrity of fertilizer granules are key when producing a high-quality product for crop nutrition. Granulation aids help achieve this by increasing crush strength, improving size distribution and reducing recycling volumes during manufacturing. Christina Konecki of Arkema-ArrMaz outlines how their performance can be properly evaluated.

Market Insight courtesy of Argus Media

Conventional fertilizers can be transformed into enhanced efficiency fertilizers (EEFs) using coating agents and inhibitors. Greater use of EEFs, by preventing nutrient losses and avoiding excess nutrient supply, can help global agriculture become more sustainable, as Urvi Mathur of Neelam Aqua explains.

Yield, quality and profitability are the primary focus for the modern potato grower. But these objectives need to be balanced against the need to reduce the environmental impacts that result from cultivating the world’s fourth-biggest food crop. Fertilizer International talks to David Marks of Levity Crop Science about how its unique approach to product development is helping farmers adopt more sustainable agricultural practices.

New innovations and the latest equipment options from FEECO International, Casale, thyssenkrupp Fertilizer Technology and Eirich are helping to perfect the fertilizer finishing process.

Market Insight courtesy of Argus Media

A detailed rain and wastewater concept is an important part of a urea plant to meet current stringent environmental standards. Wastewater can originate from the process reaction or from outside the process equipment. In order to optimise the wastewater system of a urea plant, both the amount and type of contamination need to be known. With this knowledge, non-contaminated rainwater as well as process drains can be kept separate as much as possible to minimise the amount of wastewater to be treated, saving costs and energy. Wastewater treatment concepts from thyssenkrupp Industrial Solutions and Toyo Engineering Corporation are described.

Every urea plant continuously fights again corrosion. The intermediate product ammonium carbamate is extremely corrosive under synthesis conditions. The applied materials of construction require oxygen to form a protective passive layer of chromium oxides. The ammonium carbamate solution will continuously dissolve the passive layer, therefore it is vital to continuously supply oxygen, typically in the form of air, to maintain the passive layer. During blocking-in conditions of the synthesis section it is not possible to add air and the oxygen present will be consumed as a result of the passive corrosion reactions, while at the same time the passive layer dissolves in the ammonium-carbamate solution. At a certain point, the oxygen content in the solution becomes too low to assure a passive layer. At that moment active corrosion will start with much higher corrosion rates than passive corrosion. The picture on the left side shows the passive layer (blue, brown, grey surface) and the picture on the right side shows active corrosion (a shiny silver surface). It is important to realise that once active corrosion starts it cannot be stopped, adding more oxygen at this stage, for example, will not work. Active corrosion will continue, leading to the risk that the protective layer will be severely damaged. The only way to solve this situation is to drain the synthesis section and re-passivate the surfaces.