Another lesson from an SRU shutdown

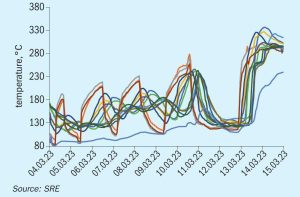

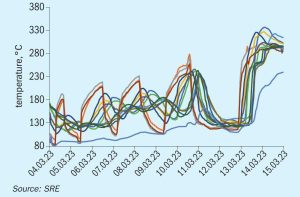

Sulfur Recovery Engineering shares the lessons learned from an emergency shutdown of an MCRC sulphur recovery unit in the middle of a cold Canadian winter.

Sulfur Recovery Engineering shares the lessons learned from an emergency shutdown of an MCRC sulphur recovery unit in the middle of a cold Canadian winter.

SO2 breakthroughs remain an ever present threat to the successful operation of reductive, quenchamine-based tail gas clean-up units (TGUs). Optimized Gas Treating presents a case study which demonstrates how SulphurPro's detailed reaction kinetics and mass transfer rate model can be used to analyse integration techniques and mitigation methods.

The world has seen a number of hydrogen explosions in double absorption plants mostly in the intermediate absorption tower (IAT). To review this increase and to determine the causes, an International Hydrogen Safety Workgroup was formed including major acid plant contractors, major acid producers, and consultants in the sulphuric acid arena. Davis & Associates Consulting explores some of the findings.

Operating plants in extreme environments can present unique challenges. If these challenges are not anticipated and addressed in design and commissioning, the plant will not be able to start up nor meet its specification. This article examines the challenges faced in commissioning amine plants operating in three diverse environments (extreme heat, extreme cold, and offshore) and the technical and procedural solutions employed to resolve them. Mike Sheilan, Ben Spooner, Kaiyr Tekebayev, and Philip le Grange , Amine Experts.

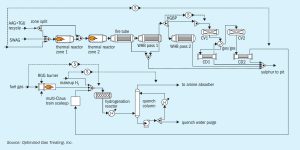

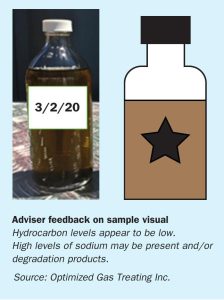

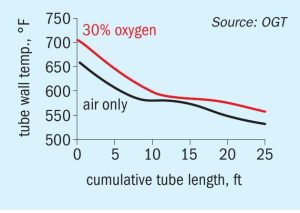

N. A. Hatcher, D. R. Jensen , and P. L. Ott of Optimized Gas Treating Inc. provide a technology overview of ProBot™ – a unit monitoring system developed by OGT to digitalise the sulphur processing assets in a facility in a manner that facilitates knowledge retention, rapid optimisation, and plant troubleshooting. ProBot™ has been built to allow rapid access to a virtual plant platform that provides advice, training and, monitoring to enable more efficient, safe, reliable, and environmentally friendly plant operations.

Process and simulation models can be valuable tools when troubleshooting to solve operational issues in sulphur recovery units. Two examples are provided. In the first case study it is shown how a tuned model was useful in troubleshooting an SRU that was experiencing lower than expected recovery efficiency and apparent channelling in the first catalytic converter. In the second case study an SRU simulation tool is used to investigate sulphidic corrosion in a waste heat boiler.

Troubleshooting and root cause analysis help to identify and solve problems in the operation of nitric acid plants and to prevent future reoccurrences. Johnson Matthey, Casale and Sabin Metal Corporation discuss their approach to solving problems in nitric acid plants to improve plant reliability and efficiency and to avoid unplanned shutdowns, costly replacement of equipment and loss of production.

Weir Minerals has the global engineering expertise to tackle the world’s harshest and most extreme mine and quarry environments. These range from Canada’s frozen north to tropical Indonesia and the remote deserts of Chile, Mongolia and Australia. This expertise extends to Florida’s phosphate mining district, where a dedicated multi-disciplinary team is delivering an integrated approach to some tough mining challenges.

As existing facilities grow older, service requirements increase. Equipment needs to be low maintenance and back in operation quickly after service and repair. Technology licensors are expanding their technical services with new digital tools, using digitalised expertise with real time insights and data driven analytics to boost chemical production and ensure that equipment operates reliably and efficiently, while maintaining product quality.

Now in its second year, SulGas 2020, South Asia’s only conference on gas treating and sulphur recovery, took place 3-4 February 2020 at the Novotel – Juhu Beach, in Juhu, Mumbai, India.